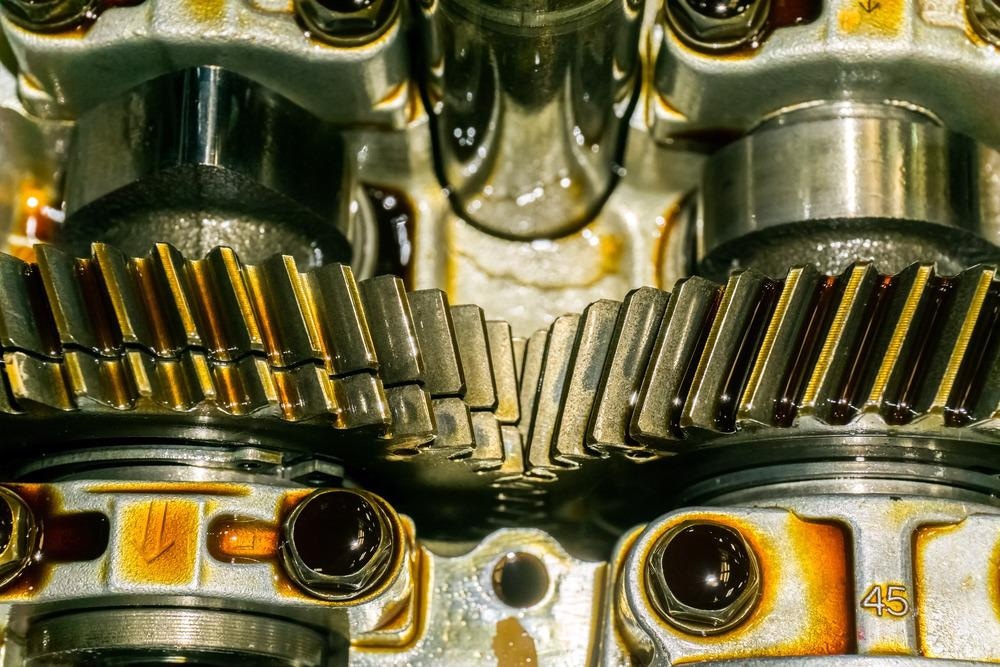

Lubricating oils and lubricants are essential for the design and development of machines and devices. Chromium nitride (CrN) coatings are capable of reducing friction between essential parts; scientists have studied the properties of different CrN coatings in order to identify those with the best wear-reducing properties.

Image Credit: jeab05/Shutterstock.com

The Environmental Impact of Mineral Lubricants

For the design and development of machines and devices, lubricating oils and lubricants create a layer in the form of a microfilm between moving elements of the device.

The presence of lubricants between these elements can minimize friction and corrosion, reduce scuffing of rubbing machine elements, provide cooling effects, as well as washing carbon deposits and microparticles.

Since most lubricating oils are produced from crude oil, their production is often dependent upon conventional oil refining processes.

Typically, crude oil is obtained by pumping liquid oil out of the ground through the use of drilling rigs and wells capable of accessing pockets of oil resources. Since many drilling oil rigs are set on platforms within the ocean, the risk of large oil spills capable of causing extensive environmental damage remains.

In addition to oil spills, the mismanagement or recycling of used lubricants can also lead to pollution of the environment through stormwater runoff or direct discharge on land or water.

Advantages of Glycerol Lubricants

In an effort to reduce the environmental impact of lubricating oils, several alternative biodegradable lubricating oils have been proposed.

In particular, vegetable-based oils have been found to exhibit higher biodegradability ranging from 70% to 100% as compared to other types of base oils.

Some of the primary ingredients of vegetable-based oils include triglycerols and their derivatives, of which include diacylglycerols, monoacylglycerols, free fatty acids, and liquid glycerol.

In addition to their environmental advantages, vegetable-based oils also exhibit high efficiency over a wide temperature range, as well as a high lubricity, viscosity index, and polarity.

Despite these advantages, vegetable-based oils are associated with low-temperature properties and oxidative stability, which has caused many industries to still rely on the use of certain additives to overcome these issues.

Notably, glycerol-based lubricants have emerged as highly desirable lubricating agents as a result of their improved low-temperature characteristics as compared to conventional vegetable lubricants.

Furthermore, glycerol exhibits much lower friction than conventional vegetable and mineral oils.

What are CrN-Based coatings?

One of the most prominent coatings that have been incorporated into the fields of cutting tools, automotive manufacturing, shipbuilding, and aerospace is chromium nitride (CrN) coatings.

Despite the excellent mechanical properties and wear resistance of CrN coatings, these materials are limited as a result of their large grain size, high friction coefficient (COF), high wear rate, and low corrosion resistance.

Image Credit: RossHelen/Shutterstock.com

Thus, several elements line titanium (Ti), silicon (Si), copper (Cu), and aluminum (Al) have been investigated for their ability to improve the tribological properties of these coatings.

CrCN-2A Coating with Glycerol

Aside from the addition of various elements, lubricating oils have also been studied for their ability to reduce the friction and wear of CrN coatings. With special attention on the environmental impacts of mineral-based lubricating oils, a recent group of scientists sought to investigate the compatibility of glycerol with CrCN coatings.

In their work, the researchers deposited CrCN coatings on a 304 stainless steel surface at three different currents of 1A, 2A, and 3A, thus leading each of these new coatings to be denoted as CrCN-1A, CrCN-2A, and CrCN-3A, respectively.

Glycerol lubrication of each of these coatings was then applied, followed by the evaluation of the COF values of these coatings under different loads.

Ultimately, the researchers found that the surface particles of the CrCN-2A were finer and more uniform, as compared to the irregular surfaces of the CrCN-1A and CrCN-3A coatings that exhibited large and irregular particles.

The CrCN-2A coating also exhibited the highest hardness value of 17.56, which is believed to be the result of the deposition current of 2A.

When the tribological performance of the CrCN coatings was assessed under glycerol lubrication, the researchers observed that the COF of the CrCN-2A coating could be stabilized to about 0.02 in 1,500 seconds (s). As the load increased, the COF of the CrCN-2A remained stable.

Industrial Applications

Taken together, the results of the discussed study find that glycerol exhibits excellent tribological properties on CrCN coatings.

The researchers anticipate that their novel material could effectively enhance the friction and wear properties of CrCN coatings that are often used on stainless steel surfaces in various industrial settings.

References and Further Reading

Nowak, P., Kucharska, K., & Kaminski, M. (2019). Ecological and Health Effects of Lubricant Oils Emitted into the Environment. International Journal of Environmental Research and Public Health 16(16). doi:10.3390/ijerph1613002.

Guidelines for Environmentally Sound Management of Used Oils in the Mediterranean [Online]. Available from: https://wedocs.unep.org/bitstream/handle/20.500.11822/7760/-Guidelines_for_environmentally_sound_management_of_used_oils_in_the_Mediterranean-2015guidelines_for_environmentally_sound_management_oil_eng.pdf.pdf?sequence=3&isAllowed=y.

Stimulating the lubrication behavior of glycerol – A green lubricant [Online]. Available from: https://nim.nsc.liu.se/projects/3454/.

Liu, N., Gao, J., Xu, L., et al. (2021). Effect of Carbon Target Current on Ultralow Frictional Behavior of CrCN Coatings under Glycerol Lubrication. Coatings 11(10); 1155. doi:10.3390/coatings11101155.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.