Ceramic powder is used extensively across a variety of application areas, whose particle size distribution significantly impacts product performance. This article introduces the importance of particle size distribution in the ceramic industry.

Ceramics. Image Credit: Bettersize Instruments Ltd.

Measurements for particle size of ceramic powder were conducted where the high resolution and excellent repeatability of the particle size analyzer were evident.

The Significance of Particle Size Distribution in the Ceramic Industry

In 26,400 BC, the first ceramic statue made from clay was fabricated in Brno, Czech Republic. Early examples of pottery emerged in Eastern Asia tens of thousands of years later (16,400 BC) in the Xianrendong cave in China.

One of the first significant advances in the manufacturing of ceramics was the invention of the wheel in 1,900 BC by the Sumerians in Mesopotamia.

Modern ceramics has progressed to the point that state-of-the-art ceramic coatings are now applied to car bodies, and ceramic processing is taking advantage of nanotechnology. These advances allow manufacturers to introduce materials and products with atypical properties, such as ductile ceramics, transparent ceramics, hyperelastic bones and microscopic capacitors.

Each of these innovations played a significant role in society and helped the ceramics world market reach USD 133.20 billion in 2018, which is projected to grow to USD 243.12 billion by 2026.

The performance of ceramic products is deeply impacted by numerous factors such as sintering temperature and time, dispersion degree or particle size distribution of ceramic powder.

The control of particle size distribution of ceramic powder is vital in a number of applications, e.g., reduction of particle size and controlled dispersion are key areas in the electronic materials area for enhancing the electrical properties.1

Particle size distribution knowledge is a crucial requirement when manufacturing ceramic components and is absolutely necessary for the prevention of structural microvoids. Generally speaking, the control of powder particle size is of utmost importance to the ceramic industry.

Ceramic Powder. Image Credit: Bettersize Instruments Ltd.

Worthwhile Partner for Your Quality Control

The Bettersizer ST is a world-leading particle size analyzer found in quality control laboratories across the globe. The Bettersizer ST’s rugged and compact design is enhanced by the built-in efficient wet dispersion system.

It has the increased benefit of generating fast QC measurements, which assists rather than impedes the manufacturing process. An SOP function ensures the rapid acquisition of measurements which in turn provides accurate and repeatable results.

Finally, and most importantly, economical, easy maintenance gives the user a cost-efficient particle size analyzer with extremely low running costs.

Measurement of Particle Size Distribution

As technology advances, various techniques can be applied to better measure particle size: Amongst these techniques, the laser diffraction technique that the Bettersizer ST uses is the best option for both the measurement of the particle size distribution of ceramic materials as well as for the detection of coarse/grit particles in a generally fine distribution.

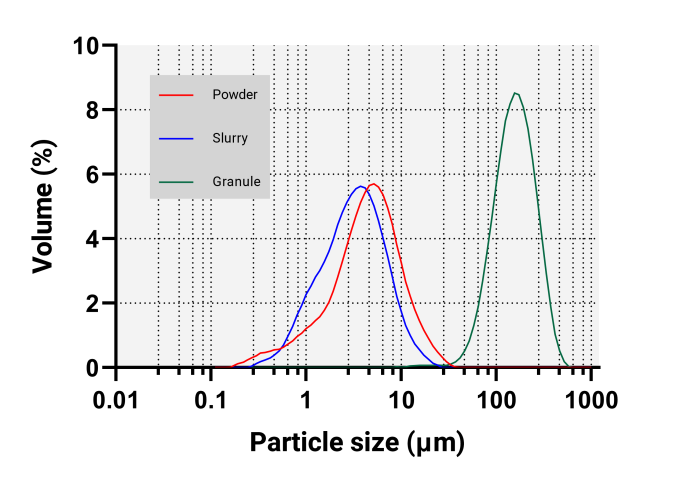

Aluminum oxide is a prime example of ceramic material, and it is available in the following forms - powder, pellets, tablets, sputtering targets and nanoparticles. In this study, the Bettersizer ST was used to measure the particle size distribution of commercially purchased aluminum oxide powder, slurry and granules.

An aluminum oxide slurry is produced through the wet milling of the raw material. Granules can be produced from the slurry with the presence of a spray dryer, and they can be deemed an agglomerate of the powder.

The measurement results of the powder, slurry and granules are displayed in Figure 1. As to be expected, the particle size distribution of the granule is greater than those of the powder and slurry.

Figure 1. Particle size distributions of powder, slurry and granule of alumina measured with the Bettersizer ST. Image Credit: Bettersize Instruments Ltd.

The particle size distribution of the powder and slurry are almost identical but these two samples can be identified on the comparison graph, which is displayed in Figure 1; the powder being marginally coarser reveals the high resolution of the Bettersizer ST.

Rapid and accurate measurements of various process samples throughout the manufacturing process can be achieved with relative ease using the Bettersizer ST, thus ensuring the quality of the product.

Repeatable Results Provided by the Bettersizer ST

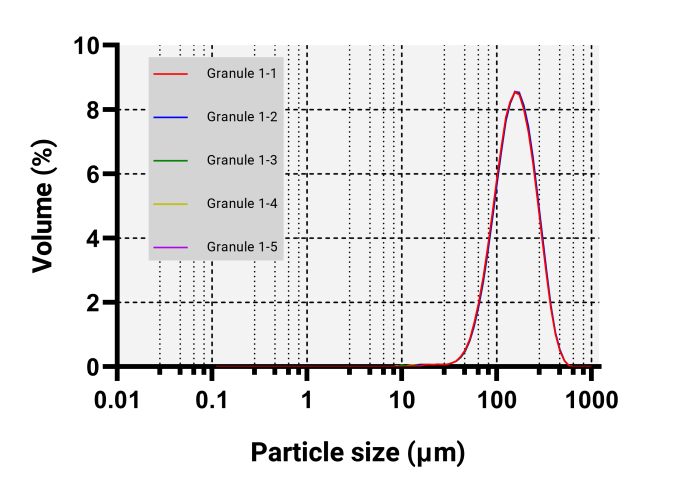

Throughout manufacturing, a particular application-specific particle size distribution is necessary where the granular powder is concerned.

Such a sample was acquired from aluminum oxide granules and measured five times with the Bettersizer ST, whose particle size distributions, D10, D50 and D90 values are exhibited in Figure 2 and Table 1, respectively.

The near-perfect overlapping of the five particle size distribution curves and first-rate repeatability calculated demonstrate that the Bettersizer ST has the capacity to deliver repeatable results that can be trusted.

Figure 2. Particle size distribution of five measurements of granule. Image Credit: Bettersize Instruments Ltd.

Table 1. Comparison of D10, D50 and D90 of five measurements of granule and corresponding repeatabilities. Source: Bettersize Instruments Ltd.

| Sample |

D10 (µm) |

D50 (µm) |

D90 (µm) |

| Granule 1-1 |

75.18 |

146.62 |

70.7 |

| Granule 1-2 |

75.99 |

148.42 |

73.6 |

| Granule 1-3 |

76.12 |

148.92 |

74.2 |

| Granule 1-4 |

75.48 |

148.12 |

73.2 |

| Granule 1-5 |

76.38 |

149.12 |

74.2 |

| Repeatability |

0.65 % |

0.67 % |

0.53 % |

Conclusion

Three forms of aluminum oxide, specifically powder, slurry and granule, were evaluated using the Bettersizer ST. Exceptional repeatability was exhibited by the measurements of the most difficult of these samples – the granule sample.

In conclusion, the Bettersizer ST can be an invaluable partner for product quality control from both a repeatability and accuracy perspective.

Reference

Deb Shechter (Sep 8, 2015) Particle Size Reduction & Distribution in the Ceramics Industry. Available at: https://www.beei.com/

This information has been sourced, reviewed and adapted from materials provided by Bettersize Instruments Ltd.

For more information on this source, please visit Bettersize Instruments Ltd.