Over the past few years, the production of biofuels from renewable feedstock has grown exponentially. As it can be produced from (renewable) raw materials rich in starch and sugars, bioethanol is one of the most interesting alternatives for fossil fuels.

Image Credit: Metrohm Middle East FZC

Fermenting corn starch to generate ethanol for fuel is a complex biochemical process that requires the monitoring of numerous parameters to ensure optimal production.

Measuring these parameters using traditional laboratory methods is a limiting step for increasing plant capacity and efficiency and takes about an hour to complete. Near-infrared spectroscopy (NIRS) can replace routine laboratory analysis, increasing plant efficiency and capacity and decreasing operating costs.

Producing High Quality Ethanol as a Fuel Additive

In the worldwide fuel market, ethanol is an increasingly vital component as countries look to reduce their greenhouse gas emissions relative to fossil fuels and secure domestic fuel supplies. Brazil and the United States lead global bioethanol production and make up 83% of the supply.

Image Credit: Metrohm Middle East FZC

In 2020, around 26 billion gallons (almost 100 billion liters) of ethanol were produced worldwide.1 Due to the global pandemic crushing demand for gasoline and ethanol, this was slightly down from a 2019 peak.

As the United States increases the adoption of E15 blends (15% ethanol in gasoline), the demand for corn to transform into ethanol is still likely to grow.2 With countries such as China implementing an E10 fuel standard for motor vehicles, ethanol for export is also likely to grow in demand.

Increasing plant capacity is one of the key ways to meet increasing product demand while maintaining price competitiveness. Yet, for growing a production site or improving its efficiency, the standard laboratory analytical workflow for monitoring the different parts of the fermentation process can be a limiting factor.

The seasonal and even regional variation of feedstock quality is another consideration, needing ethanol producers to closely monitor the fermentation process to ensure the same quality product is achieved.

A report from the National Renewable Energy Laboratory estimated that nearly 40% of the production cost of fuel ethanol from corn comes from supplies, labor, overhead and variable operating costs.3

Optimization of these costs, which include regular maintenance of the fermenters and distillation towers, routine quality checks of the fermentation broth and triaging process upsets in a timely manner, results in higher profitability of the ethanol production facility.

Laboratory limitations must be overcome to maximize bioethanol production and profitability. Near-infrared (NIR) spectroscopy is a proven rapid, economical and operator-friendly way to overcome common laboratory limitations.

Some background information about the production of bioethanol is outlined below before moving on to how to optimize the process.

Image Credit: Metrohm Middle East FZC

Ethanol Process: Wet vs. Dry Milling

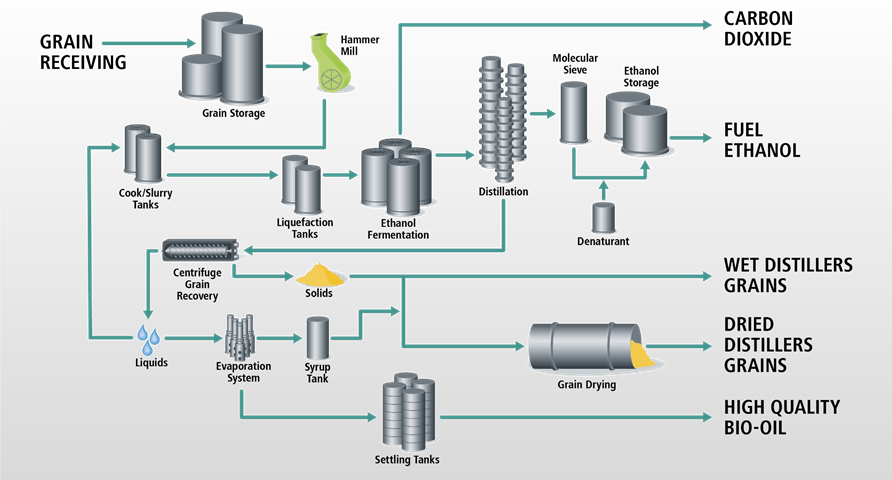

When it comes to creating ethanol from starches and sugars from starting materials such as corn, there are two main production processes: the wet milling process and the dry milling process, as seen in Figure 1.

Figure 1. Schematic representation of the dry mill ethanol process. Image Credit: Metrohm Middle East FZC

Almost all ethanol produced for fuel in the U.S. (the largest bioethanol manufacturer in the world) is made by utilizing the dry mill process.2 Firstly, grains are ground into smaller, more homogenous particles in the dry milling process, which enables the husk or shell to be penetrated more easily.

Enzymes and water are then added to create a slurry known as a mash. The mash is heated to specific temperatures to facilitate the conversion of starches to sugars, then cooled before yeast is added.

The yeast does the work of creating ethanol from the converted sugars via the process of fermentation. Yet, the percentage of ethanol is still quite low, and to obtain the concentration and purity necessary for fuel additives, the solution must be distilled and dehydrated.

Wet milling differs from this process by first soaking the grains before grinding and separating out the various components. Just as with dry milling, the starches are then converted to sugars which are utilized for the fermentation process.

Lab Analysis Shortfalls

The lab serves many functions, but monitoring the progress of the fermentation in each fermentation tank is one of the key functions. Usually, this requires many different technologies, as a number of parameters must be checked to ensure that fermentation is on track.

Tight monitoring and control over the different sugars present (e.g., glucose, maltose, DP3, etc.) throughout the fermentation process is needed to understand the breakdown pathway of the starch (glucose generation) present in the mash and optimize ethanol production.

Understanding this pathway permits the proper dosage of enzymes and yeast to the mash in the slurry tanks to accelerate breakdown, as seen in Figure 1. So, optimizing the yeast and enzyme blend is vital for this process.

These are the highest consumable costs for ethanol production and significantly influence the rate of production and final yield of ethanol. Table 1 shows some of the most common analytical instruments and their use cases.

Table 1. Typical instruments and parameters that are measured during fermentation of corn to ethanol. Source: Metrohm Middle East FZC

| Parameter |

Measurement technique |

Analysis time (min) incl. sample prep. |

| Dissolved solids (°Bx) |

Refractometer |

3–5 |

| pH |

pH meter |

3–5 |

| Solids (non-volatiles) |

Infrared balance |

15–20 |

| Ethanol |

HPLC |

30–45 |

| Sugar profile (DP2, DP3, DP4+, glucose, total sugar) |

HPLC |

30–45 |

| Glycerol |

HPLC |

30–45 |

| Lactic acid |

Ion chromatography |

30–45 |

| Acetic acid |

Ion chromatography |

30–45 |

| Water content |

Karl Fischer titration |

5–10 |

It can easily take an hour and six different pieces of equipment if all the properties in Table 1 are to be measured. The time for a routine fermentation analysis increases when factoring in conditioning steps and reference scans to ensure proper calibration.

This can take over 55 hours for a single corn fermentation, an hour to carry out the analysis and six hours between each measurement. Yet, increasing the number of concurrent fermentations to four or six means that measurements from the different tanks will start to overlap.

For bioethanol producers, the overlapping instrument demand combined with long analysis times leads to a variety of different challenges. First, if scheduled sampling times overlap, then samples must age while waiting for analysis or sampling must be delayed.

Second, the long analysis time means that data is no longer current, but by the time it has been communicated to the plant control center, it is minimally one hour or older, which lowers its ability to deal with deviations. For manufacturers, neither of these situations are ideal as time is money.

Image Credit: Metrohm Middle East FZC

Infrequent measurements and long laboratory analysis times decrease the ability to carry out interventions or to adjust other critical parameters (e.g., process temperature or enzyme addition rate). Furthermore, such long wait times can impede the decision to end fermentation early and begin anew if the batch is judged to be beyond recovery.

Faster Measurements Equal Higher Profits

The most obvious way to overcome measurement time challenges is to add automation and/or to increase the number of tools in the lab. Yet, this method has costs in time; twice the sample preparation increases operating expenses and still fails to provide high-speed feedback to the plant operations team.

Using near-infrared spectroscopy (NIRS) is a better way to overcome measurement time delays. It can perform all of the traditional laboratory measurements with one piece of equipment, simultaneously in under five minutes.

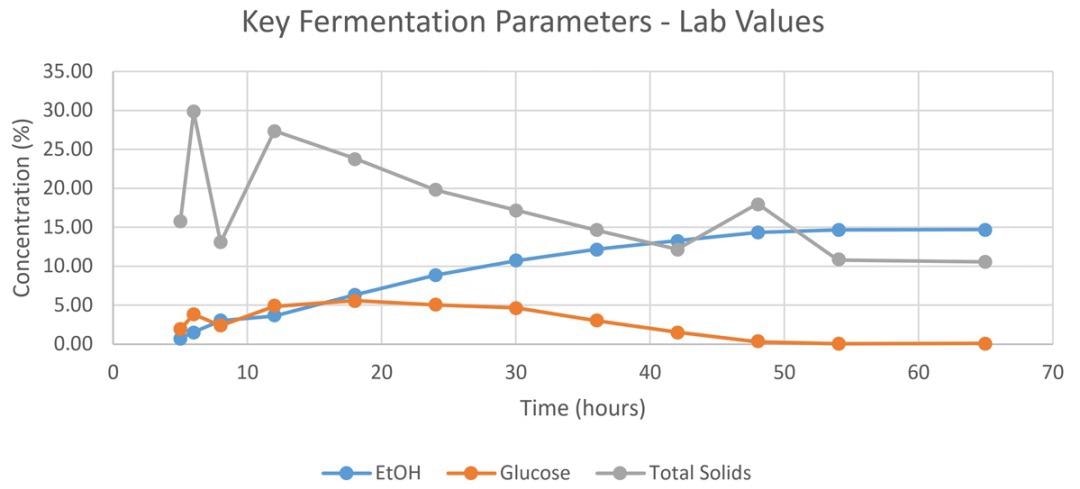

The average ethanol concentration from HPLC measurements during numerous fermentations from one plant is shown in Figure 2. In the first 12 hours, the data demonstrates apparent discontinuities, with spikes in dissolved solids and glucose.

Figure 2. Key parameters measured for corn fermentation to ethanol as reported by the primary analysis methods listed in Table 1. Image Credit: Metrohm Middle East FZC

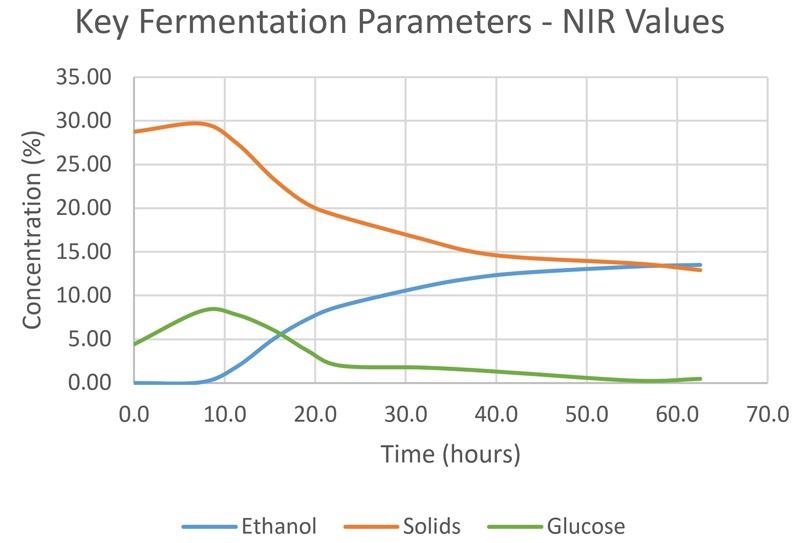

It is also clear that the total solids measurement at 48 hours is erroneous. Yet, this spike is ignored instead of retested as the lab data takes so much time to gather. The NIRS alternative to traditional measurements displayed in Figure 3 is of a single fermentation monitored in near real-time.

This high-speed analysis is possible because sample preparation is trivial for NIRS. Compared to the combination of HPLC and other analytical techniques, which takes around an hour of operator time per sample, NIRS measures the same parameters and gives a quality result in around a minute.

The ability to gather many NIR spectra in the early stages of the fermentation process supplies a higher fidelity picture, permitting more timely interventions to maximize ethanol production.

By growing the number of batches and revenue, as displayed in Table 2, the higher speed NIRS analysis can be used to increase the total plant throughput. With traditional analysis, the fermentation is permitted to run for 62–65 hours, depending on the final laboratory results (Figure 2).

Figure 3. Corn fermentation to ethanol as measured by near-infrared spectroscopy. Image Credit: Metrohm Middle East FZC

This fermentation is complete in approximately 56 hours with NIRS analysis, as seen in Figure 3. Over the course of a year, decreasing fermentation time by six hours expands the potential number of batches by 13, representing a potential plant capacity increase of 10%.

Table 2. Comparison of the apparent fermentation time based on primary lab analyses vs NIRS analysis. Source: Metrohm Middle East FZC

| |

Traditional Lab Analysis |

NIRS analysis |

| Total measurement time |

12 hours |

5 hours |

| Number of measurements |

12 |

62 |

| Fermentation end point |

~62 hours |

56 hours |

| Batch capacity |

37,850 L |

37,850 L |

| Batches per year |

129 |

142 |

Near-Infrared Spectroscopic Solutions for Ethanol Producers

To make analysis easier and optimize production, Metrohm provides a number of NIRS solutions for ethanol producers. The DS2500 Solid Analyzer seen in Figure 4 is ideal for the fast laboratory analysis of numerous critical quality parameters in the fermentation process.

Furthermore, Metrohm also makes NIRS instruments for measurements directly in the process, circumventing the requirement for removing samples and transporting them to the laboratory. Measurements collected using this method are the most representative of actual process conditions and so supply the highest quality data to operators.

Data communication between the control room and process analyzer enables a direct overview of current conditions without delays and provides the possibility of integrating warnings when readings are out of specification or informing operators when the fermentation process is deemed to be complete.

Figure 4. The Metrohm DS2500 Solid Analyzer. Image Credit: Metrohm Middle East FZC

Summary

For in-process fermentation samples, near-infrared analysis lowers measurement time by approximately 90%, from one hour to five minutes. Quicker measurements enable the fermentation process to be followed much more closely, saving operator time to decrease costs and to optimize process conditions and plant operations.

Capacity enhancements of 10% are viable by being able to stop the fermentations based on the rapid determination of the different parameters in the fermenter with NIRS instead of by slower traditional laboratory techniques.

NIR methodology can supply advantages across the ethanol plant beyond fermentation monitoring to measure the performance of other plant components such as a centrifuge or dryer, making it a valuable tool to improve operations across the facility.

References

- Annual Fuel Ethanol Production U.S. and World Ethanol Production. Renewable Fuels Association: Washington, DC, 2021. https://ethanolrfa.org/statistics/annual-ethanol-production/

- Essential Energy: 2021 Ethanol Industry Outlook. Renewable Fuels Association: Washington, DC, 2021. https://ethanolrfa.org/wp-content/uploads/2021/02/RFA_Outlook_2021_fin_low.pdf

- Determining the Cost of Producing Ethanol from Corn Starch and Lignocellulosic Feedstocks. National Renewable Energy Laboratory (NREL): Golden, Colorado, USA, 2000. https://www.nrel.gov/docs/fy01osti/28893.pdf

Acknowledgments

Metrohm Middle East FZC (MME) based out of Sharjah, UAE is the Regional Support Centre for Metrohm AG (Switzerland) which is responsible for sales, service and calibration of lab & process analytical instruments from the following countries –

UAE, KSA, Kuwait, Bahrain, Oman, Qatar, Egypt, Jordan, Lebanon, Iraq, Bangladesh, Pakistan, Sri Lanka, Ethiopia, Ghana, Sudan, Syria, Yemen, Somalia, Iran, Cyprus, Malta, Eritrea, Djibouti & Afghanistan.

Produced from materials originally authored by Dr. Adam J. Hopkins and Dr. Alyson Lanciki Metrohm International.

This information has been sourced, reviewed and adapted from materials provided by Metrohm Middle East FZC.

For more information on this source, please visit Metrohm Middle East FZC.