The analysis and monitoring of lubricant oil formulations play a critical role in lubricant oil manufacturing and in understanding the performance of lubricant oils over time.

Image Credit: Waters Corporation

Here, the RADIAN ASAP System was utilized for the fast analysis of lubricant oil, with little sample preparation needed and the deployment of a thermal gradient to help deconvolute the complex sample.

By using this approach, the key compounds in the additive package and the base oil itself were identified easily. This simple technique can be used by analytical lubricant technicians or scientists to quickly observe changes in the components of their lubricant oils, as well as speed up the decision-making process in formulation design.

Benefits

- Fast and easy to use, with a simple “dip and analyze” approach

- Minimal sample preparation is required

- Temperature ramping functionality allows for thermal deconvolution of complex samples

- Within minutes, data is made available, enabling accelerated business decisions to be made

- With no need for an additional separation system and a small instrument footprint, the deployment of laboratory real estate can be maximized

Lubricant oils have an array of industrial applications, including vehicle engines and process machinery – any circumstance where surfaces come into contact and wear could be a potential problem.

To ensure proper performance for a specific application, lubricant oils are formulated from the base oil and an additive package. The additive package is created specifically for its application, conforming to particular performance characteristics required by the lubricant oil.

currently, several different methodologies and tests exist for lubricant oil additive analysis, but these have varying limitations.

Some only focus on specific elements, e.g., zinc in zinc dialkyl dithiophosphates (ZDDP) using ICP-AES,1,2 whilst others are non-specific, e.g., FTIR that identifies the presence of specific functional groups but cannot identify the exact molecules of interest.3

This article demonstrates the benefits of utilizing rapid and direct analysis with mass detection to discover and monitor lubricant oil additives.

Results and Discussion

A domestic car engine lubricant oil that is commercially available was analyzed in triplicate using the RADIAN ASAP System. The oil was dissolved in 9:1 toluene:methanol with 0.1% formic acid, making a final solution of 1 mg/mL.

Before analysis, 1 mL of the solution was pipetted into an ACQUITY vial, producing a solution of a known depth and volume.

For each analysis, a new glass-sampling rod (capillary) was used. Using the RADIAN ASAP System, each glass capillary was cleaned using a fast, automated “bake-out” procedure.

This procedure exposes the tip of the capillary to a stream of high-temperature gas, burning off any residual contaminate that may have been transferred from the glass capillary packaging.

A simple “dip and swirl” technique was used to sample the solution for 15 seconds for each analysis. By pipetting 1 mL into the ACQUITY vial and then sampling for identical amounts of time, it was ensured that the exposure of the glass capillary to the analyte was reproducible throughout the entire experiment.

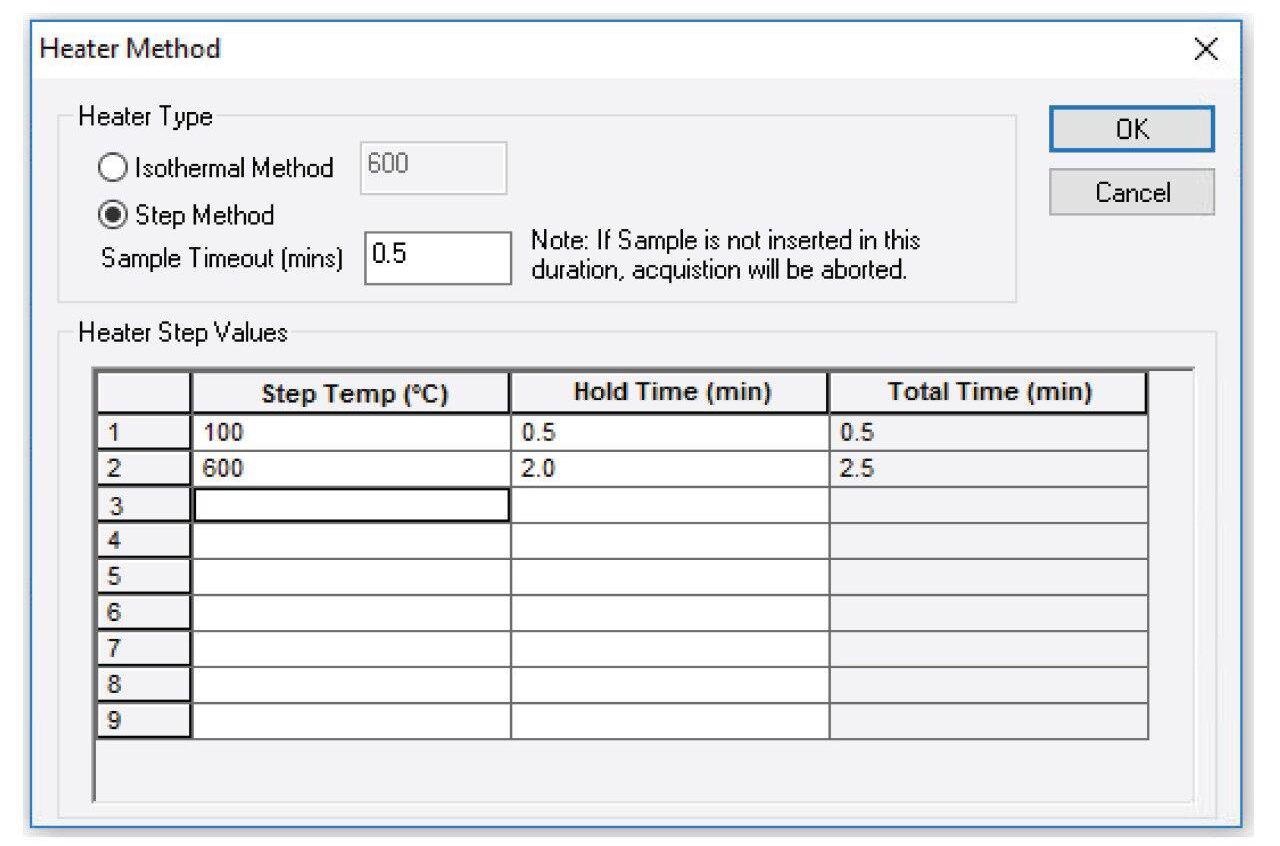

The data was collected using an automated ballistic temperature ramp from 100 °C to 600 °C, over two minutes; this was pre-programmed in MassLynx instrument control software (Figure 1).

Figure 1. The pre-programmed temperature ramp used for the analysis of domestic car engine lubricant oil. Image Credit: Waters Corporation

The use of a temperature ramp facilitated a degree of deconvolution of the complex sample as different components emerged at different boiling points. Additionally, this ensured the rapid evolution of information-rich data.

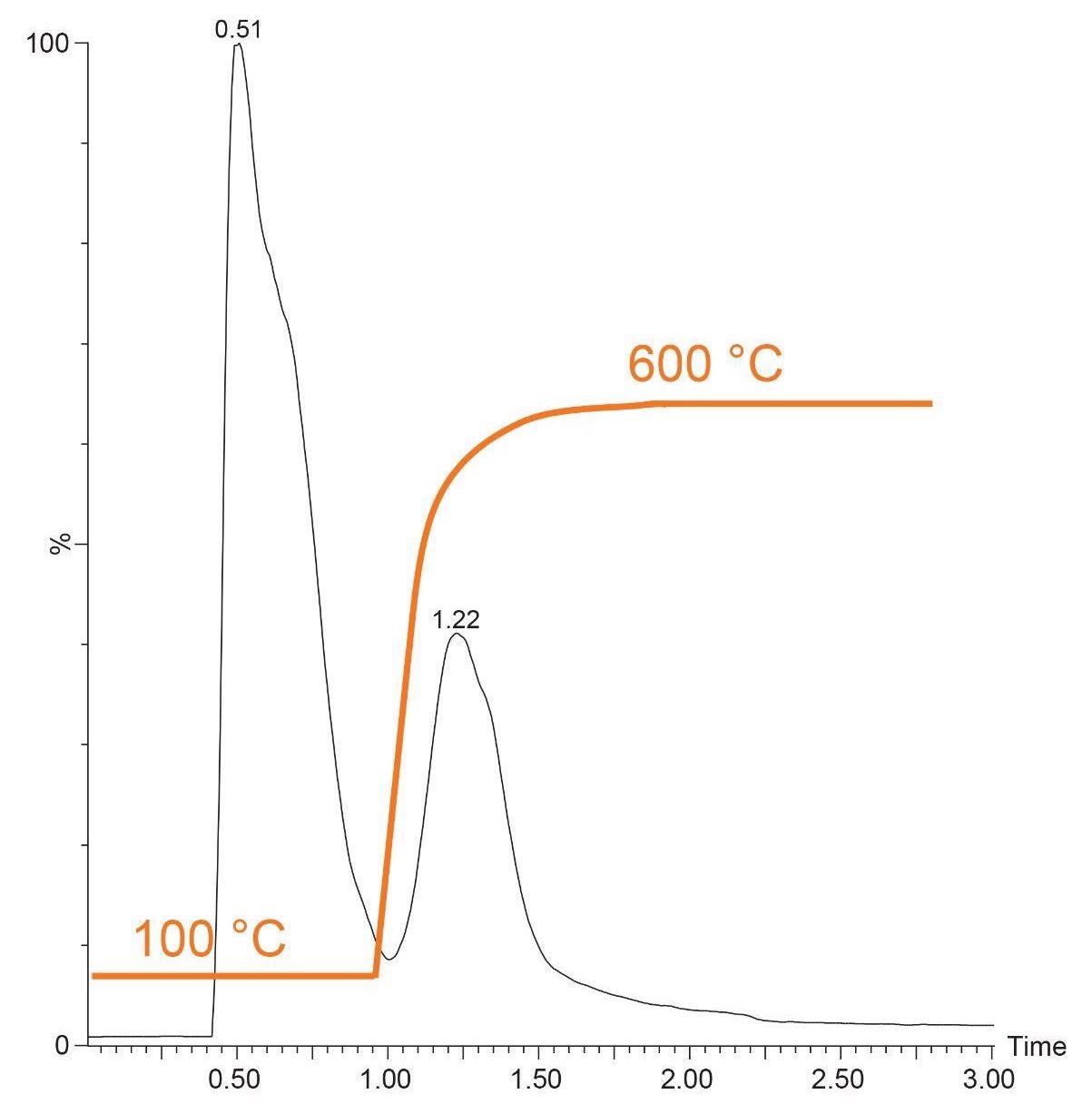

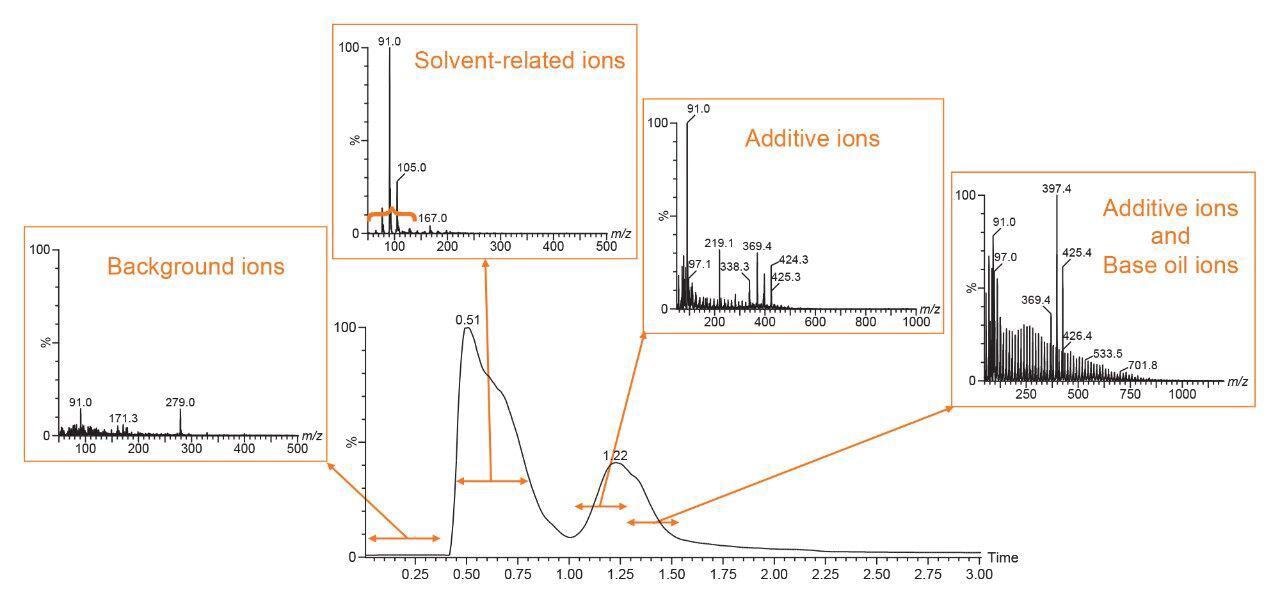

Figure 2 denotes the resultant thermal profile generated as different ions are produced with the applied temperature ramp overlaid. Figure 3 shows the mass spectrums generated at varying points in the thermal profile.

Figure 2. The thermal desorption profile (black line) resulting from the temperature ramp, with an overlay showing the temperature gradient profile (orange line). Image Credit: Waters Corporation

Figure 3. Spectra showing the ions evolved at different stages during the temperature ramp. Image Credit: Waters Corporation

As a result of the ionization approach used by the RADIAN ASAP, the components of the lubricant base oil and the lubricant oil additive package can be distinguished.

Lower mass (smaller) species, including solvent-related species, were observed to evolve at lower temperatures shortly after initial insertion of the capillary, and higher mass (larger) species evolved as the temperature increased.

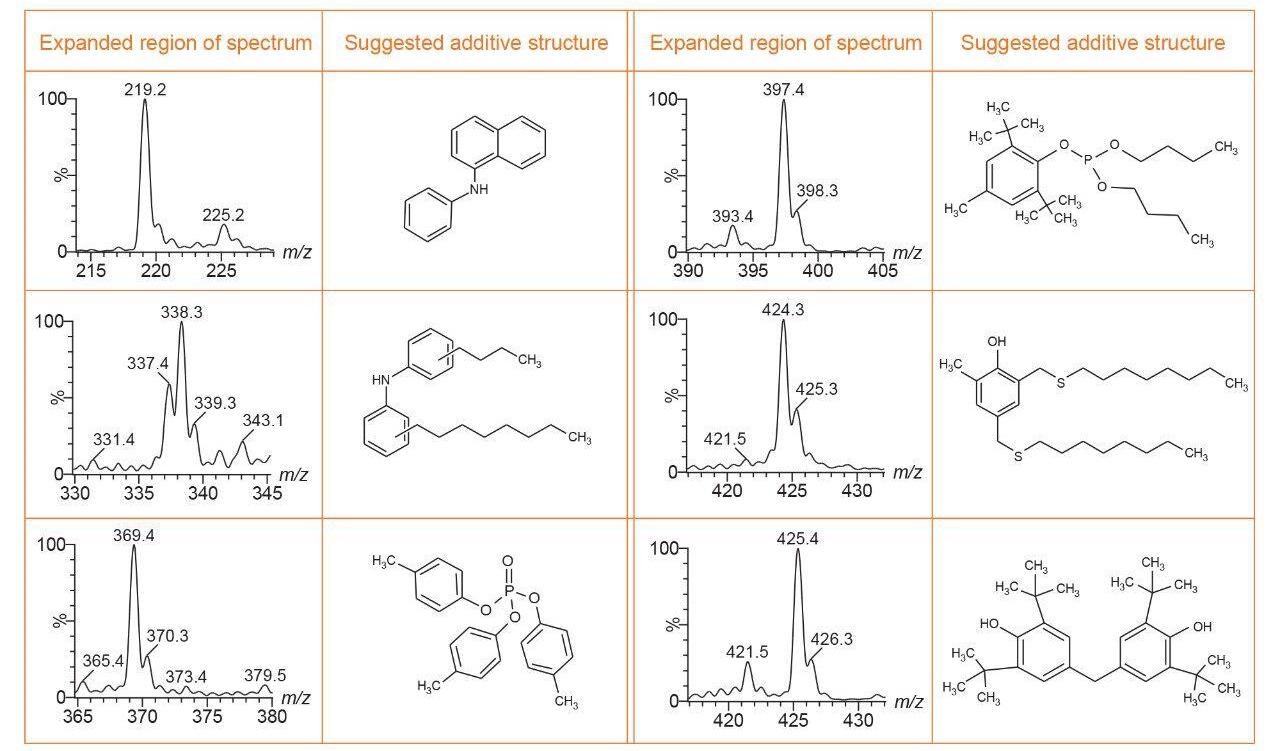

Figure 4 illustrates magnified regions of the mass spectrum that correspond with examples of additive species identified in a sample of the commercial car engine lubricant oil and the associated proposed chemical structures.

Figure 4. Selected expanded regions of the spectra are shown in Figure 3 with associated suggested additive structures. Image Credit: Waters Corporation

These ions can be then be monitored, ensuring the constant presence of essential additive components.

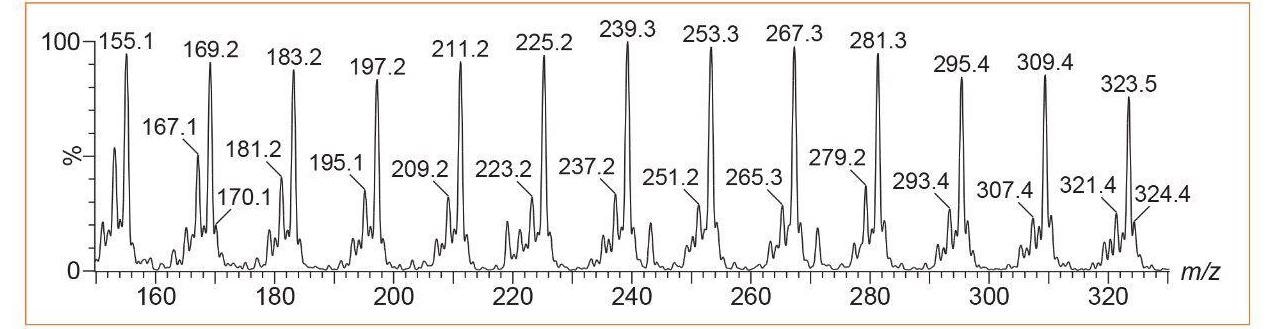

Figure 5 denotes a series of ion clusters that are typically produced by the base oil. This demonstrates that this methodology is useful for monitoring the additive package, the base oil, or both.

A single technique is used, rather than an array of instruments, to determine the full picture of the lubricant oil sample, resulting in a streamlined approach to the analytical workflow.

Figure 5. Expanded region of the spectrum produced at higher temperature showing series of ion clusters related to the base oil. Image Credit: Waters Corporation

Conclusion

The RADIAN ASAP System is a valuable tool for monitoring the components of lubricant oil. The lubricant base oil and lubricant oil additives were readily detected using a very quick and easy analysis protocol.

This system incorporates valuable features, for example, the programmable temperature ramping to aid deconvolution of complex samples and the automated cleaning of the glass-sampling capillary via a bake-out button.

In addition, the system offers the power of mass spectral sensitivity and selectivity in a small instrument footprint. The fast production of information-rich data provides a platform on which key business decisions can be made rapidly.

Acknowledgments

Produced from material originally authored by Eleanor Riches and Caitlyn Da Costa from Waters Corporation.

References

- Neikov OD, Yefimov NA. Handbook of Non-Ferrous Metal Powders. 2nd ed. Amsterdam (Netherlands): Elsevier Academic Press; 2019. Chapter 1, Powder Characterization and Testing; p. 3–62.

- Fox B. Elemental Analysis of Lubricating Grease by Inductively Coupled Plasma Atomic Emission Spectrometry (ICP-AES). Journal of ASTM International, 2005; 2(8): 1–9.

- Al-Ghouti MA, Al-Degs YS, Amer M. Application of Chemometrics and FTIR for Determination of Viscosity Index and Base Number of Motor Oils. Talanta, 2010; 81: 1096–1101.

This information has been sourced, reviewed and adapted from materials provided by Waters Corporation.

For more information on this source, please visit Waters Corporation.