The analysis and monitoring of additive chemical profiles play a critical role in advancing polymer formulation, manufacturing, research and development.

Image Credit: Waters Corporation

The RADIAN ASAP System was utilized for the fast analysis of a polymer formulation, with little sample preparation needed and the deployment of a thermal gradient to help deconvolute the complex sample.

By using this approach, the processing additives and the polymeric material were identified easily.

This simple technique can be used by formulation engineers or analytical scientists to observe the components of their advanced materials, as well as speed up the decision-making process during formulation design activities.

Benefits

- Minimal sample preparation is required

- Temperature ramping functionality allows for thermal deconvolution of complex samples

- Complementary data to traditional polymer property measurement techniques, for example, rheology and thermal analysis

- Facilitates mass-based chemical identification without recourse to central analysis labs or through lengthy liquid or gas-chromatographic or MS techniques

- APCI-based ionization offers information on intact analytes, removing the need for comparison with the NIST spectral database

- Within minutes, data is made available, enabling accelerated business decisions to be made

During the manufacturing and development stages of advanced polymer formulations, chemists, engineers and materials scientists use multiple complementary data streams from an array of measurement techniques. This data is synthesized into information, providing a deep insight into their products.

For the analysis of physical and chemical properties, techniques such as DSC, TGA, GC- or LC-MS, spectroscopic methods and Rheology are of great importance. These are not only implemented for traditional QA/QC tests but also for the optimization of production workflow and innovation in formulation research and development.

However, in the majority of cases, the lead-time in data generation can range from several hours to several days. This includes the sample preparation, measurement runs, treatment of raw data, analysis and reporting.

Strategic decisions can be made faster by compressing this lengthy process to the scale of minutes. This compression will also help reduce the gap between information and impact.

This article illustrates the benefits of using rapid and direct analysis with mass detection to discover and monitor polymer formulation additives. This method could serve as a complementary technique to traditional materials property measurement techniques, such as rheological profiling or thermal analysis.

Results and Discussion

A polymer formulation made up of four polymer-processing additives and PEG 600 was analyzed in triplicate using the RADIAN ASAP system. The formulation was dissolved in 9:1 toluene:methanol with 0.1 % formic acid, making a final solution of 1 mg/mL.

Before analysis, 1 mL of the solution was pipetted into an ACQUITY vial, producing a solution of a known depth and volume.

For each analysis, a new glass-sampling rod (capillary) was used. Using the RADIAN ASAP system, each glass capillary was cleaned using a fast, automated “bake out” procedure.

This procedure exposes the tip of the capillary to a stream of high-temperature gas, burning off any residual contaminants that may have been transferred from the glass capillary packaging.

A simple “dip and swirl” technique was used to sample the solution for 15 seconds for each analysis. By pipetting 1 mL into the ACQUITY vial and then sampling for identical amounts of time, it was ensured that the exposure of the glass capillary to the analyte was reproducible throughout the entire experiment.

A degree of separation is beneficial when working with highly complex samples. RADIAN ASAP offers many features, including the ability to apply a thermal gradient or temperature ramp, allowing the separation of components based on their different boiling points.

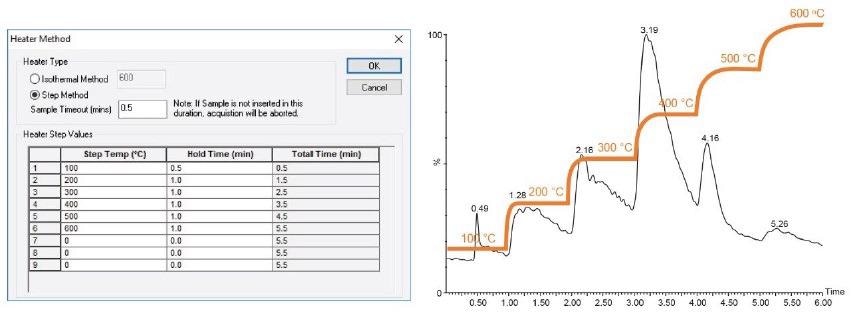

Figure 1 denotes the stepwise temperature gradient method as built-in MassLynx control software.

Additionally, the total ion chromatogram (TIC) of the analyzed formulation is overlaid with the observed temperature gradient. The chromatogram traces all of the ionized species identified by the system throughout the six-minute temperature gradient.

Figure 1. Stepwise Temperature Gradient Method in MassLynx Software and the resultant TIC overlaid with the observed temperature profile. Image Credit: Waters Corporation

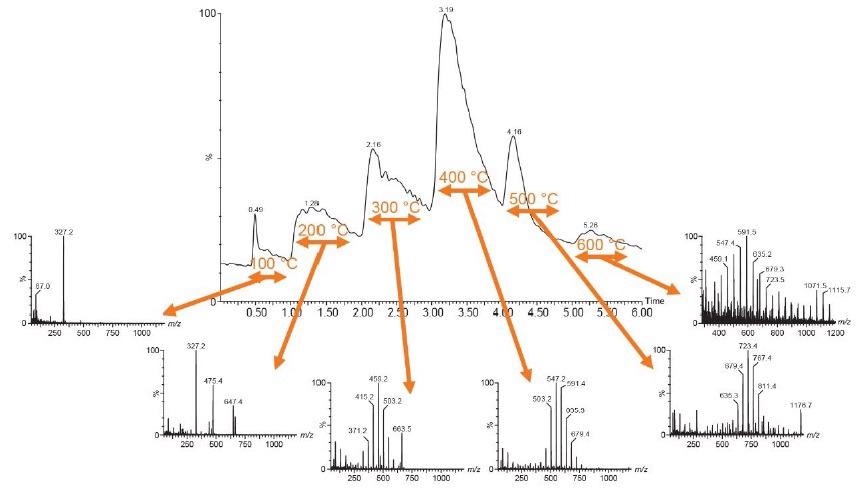

Figure 2 also displays the resulting thermal profile TIC from the pre-programmed temperature ramp, offering a view of the recorded spectra evolved at different temperatures along with the temperature ramp experiment.

Key components emerge as each boiling point is met in the thermal gradient. Usually, lower mass (smaller) species emerge at lower temperatures, with heavier mass (larger) species emerging at higher temperatures. This facilitates deconvolution of complex samples and a degree of separation.

Figure 2. TIC from analysis of the polymer formulation showing spectra evolved at different temperatures along the temperature ramp experiment. Image Credit: Waters Corporation

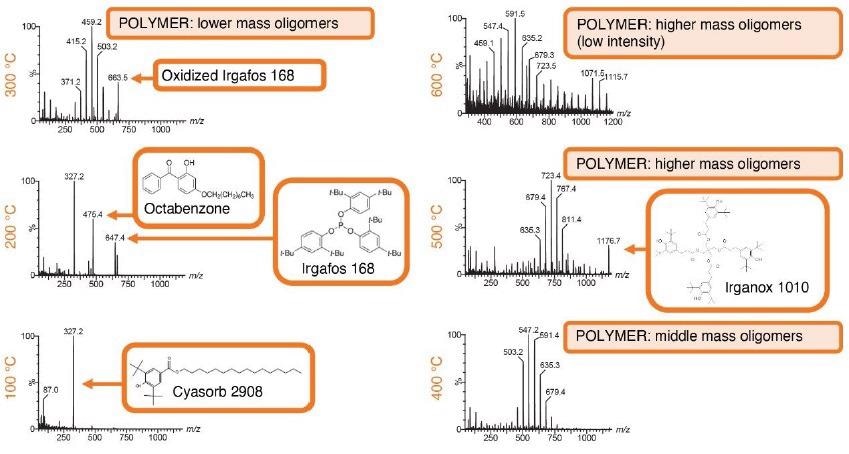

Figure 3 allocates each spectrum with the structures of the additives or names of species detected at each stage of the thermal ramp. In this case, the important polymer additives emerge at lower temperatures, except for the higher mass additive Irganox 1010 observed at 500 °C.

The polymer itself emerges at higher temperatures – starting at 300 °C and increasing to 600 °C.

The APCI-based ionization technique employed by RADIAN ASAP permits increased transmission of intact analyte ions when compared to electron impact (EI) based ionization; this is typically found in hyphenated Thermal-MS or GC-MS measurement techniques.

The information-rich data captured by RADIAN ASAP decreases the need to refer to database comparisons, such as NIST spectral databases, for identification.

Figure 3. Observed mass spectra detected assigned with the structures of the additives present at each stage of the thermal ramp. Image Credit: Waters Corporation

This methodology can be used across numerous workflows in the polymer formulation manufacturing industry, such as QC batch release based on presence of active ingredients; competitor analysis by determining chemical points of difference between competitor formulations and formulation research and development by tracking levels of key formulation ingredients through formulation use cycle.

Conclusion

The RADIAN ASAP System gives a direct insight into the chemical behavior of polymer formulations.

This example identified oligomeric species from the polymer itself and polymer additives using a simple analytical protocol. This approach generated the data within minutes and can be easily combined with physical property measurements to rapidly inform key business decisions.

Acknowledgments

Produced from materials originally authored by Michael Jones and Eleanor Riches from Waters Corporation.

This information has been sourced, reviewed and adapted from materials provided by Waters Corporation.

For more information on this source, please visit Waters Corporation.