There are many different types of XRF analyzers, all of which can be acquired in a wide variety of configurations, providing customers with a vast range of options to choose from: detector type, optics type, automation and even between a benchtop or handheld instrument.

There are several challenges that arise when measuring electronics coatings using XRF and selecting the best configuration for rapid and reliable measuring in a production environment. Care should be taken when choosing the right analyzer for the task at hand.

Image Credit: Hitachi High-Tech Analytical Science

Form Factor: Handheld or Benchtop XRF?

Nowadays, both handheld and benchtop instruments have the ability to measure the thickness of metallic coatings between 0.001 – 50 μm (0.05 – 2000 μin) on almost every kind of substrate. The key factor separating the two configurations is practicality over performance.

Suppose you are measuring extremely large components with comparatively large areas of plating that can be easily seen by the eye (and it’s easy enough to hold the instrument in hand). In that case, a handheld instrument is well-suited for the task.

However, many electronics components do not fit this description. Features may be extremely tiny and need to be located with a microscope and novel camera arrangement while utilizing precision stage and specialized optics to make sure the feature being analyzed is the right one. Thus, for electronics, benchtop is the form factor that makes the most sense.

In short, the ultimate deciding factor is the part size and the size of the specific feature being measured.

If the part can be easily be taken to the lab, then a handheld instrument is the correct choice. If the area to be evaluated is smaller than 1mm, then a benchtop instrument will be needed.

Aperture Type: Collimator or Capillary Optics?

The aperture of the instrument directs and focuses the X-Rays that are generated onto the sample surface. The resulting spot must be less than the features being measured, and the feature size will determine the optics.

XRF instruments generally come with one of two types of aperture: collimators or capillary optics.

A collimator is comprised of a metal block with a hole. Part of the X-Ray signal passes through the hole to the sample. This is an excellent choice for measuring characteristics 100 µm and larger.

Capillary optics utilizes special glass tubes that collate nearly all X-Ray signals and focus them to an extremely small spot. This allows customers to measure features below 50 µm. This technology also offers enhanced precision on thinner coatings as a greater proportion of X-Rays are used in contrast to the collimator configuration.

The ultimate deciding factor is spot size. For features less than 50 µm, capillary optics will be needed, while for larger features, a collimator setup is ideal.

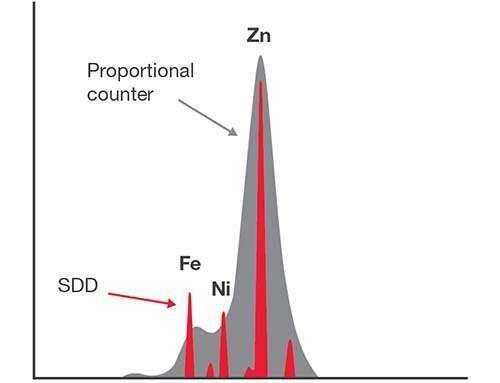

Detector Type: Proportional Counter or Silicon Drift Detector?

There are two principal types of detectors within XRF instruments: proportional counters and semiconductor-based detectors - the most common semiconductor-based detector being the silicon drift detector (SDD). It can be tricky to decide which is the best for the intended application as both technologies offer different advantages in different situations.

Proportional counters are cylinders of inert gas that ionize when flooded with X-Rays. They offer exceptional sensitivity for high-energy elements like tin or silver and are extremely effective for a basic analysis where only a few elements are present.

SDDs are semiconductor devices that generate a specific amount of charge when flooded with X-Rays. They offer enhanced resolution when several elements of interest are present within a sample or when identifying low-energy elements, such as phosphorus.

The diagram below outlines the difference in output from a proportional counter and SDD for the same sample. The red peaks exhibit the SDD output; the grey spectrum comes from the PC.

The deciding factor is not as straightforward as one would think, but if you need to measure multiple elements or very thin or complex coatings, then an SDD is the better choice.

Image Credit: Hitachi High-Tech Analytical Science

If you would like to learn more about the practical ways to optimize the reliability and accuracy of XRF analysis of minute electronics components, then download Hitachi’s free guide, Understanding your XRF: A Guide for Electronics Plating

As well as detailing the best XRF technology for a given application, this comprehensive guide includes:

- How XRF works

- How to enhance analysis throughput

- How to ensure the instrument is performing properly

- Where errors originate from

This information has been sourced, reviewed and adapted from materials provided by Hitachi High-Tech Analytical Science.

For more information on this source, please visit Hitachi High-Tech Analytical Science.