Advances have been made that can allow us to purify seawater to make it drinkable by using Graphene Oxide (GO). The process is a mixture of ion sieving and desalination.

Image Credit: Luciano Santandreu/Shutterstock.com

A team from Manchester University has developed a simple method to synthesize graphene-based membrane with limited swelling, which yielded 97% removal of NaCl, rendering the water easily drinkable. This would help provide clean, drinkable water to people, considering that the shortage of clean water is a major problem. This process would surely help cater to the problem of water shortages.

Material Incorporated

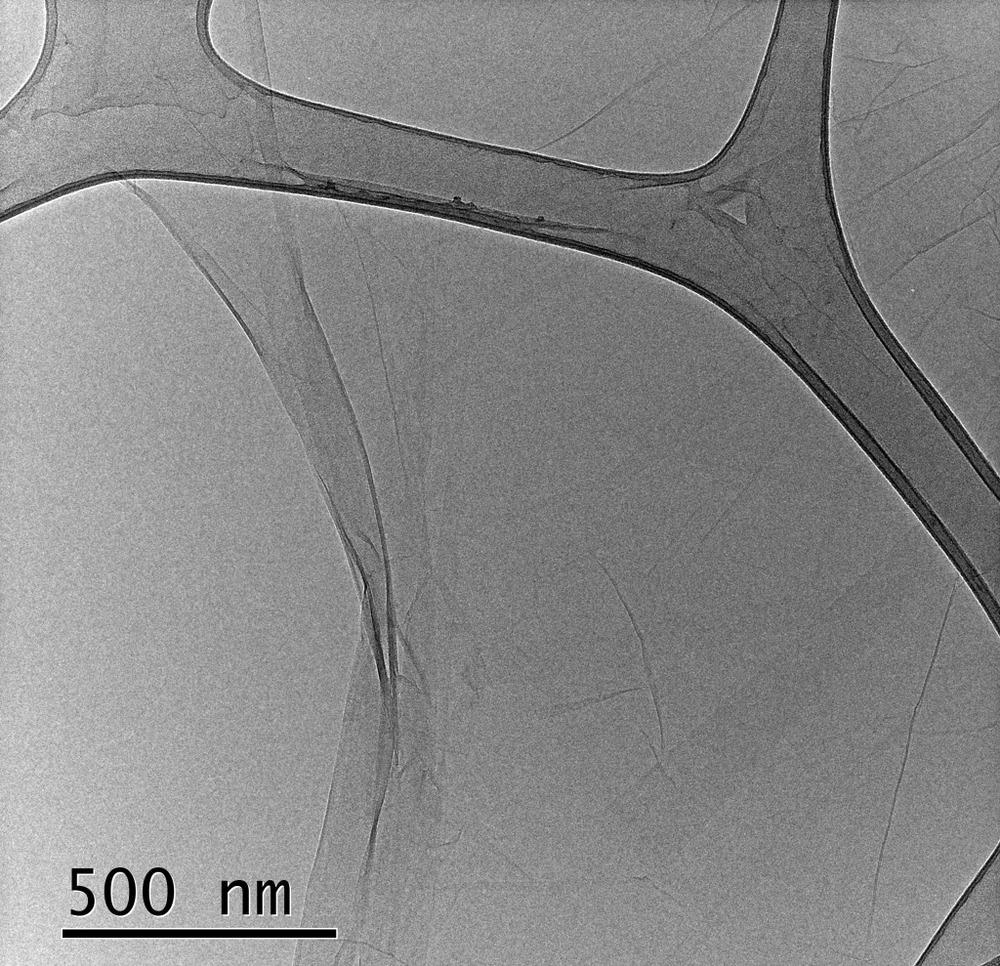

The primary material used is graphene. Graphene is a carbon allotrope comprising of a single atom layer arranged in a hexagonal two-dimensional honeycomb lattice. Because of its outstanding strength properties, electrical conduction properties, strong intramolecular bonds, and being the thinnest 2-D material, graphene has become a valued and significant nanostructure building block.

Graphene oxide (GO) is a single-layer substance created by the intense oxidation process, a cheap and reliable material. Graphene oxide is an oxidized version of graphene that has been laced with oxygen-containing groups.

Industrial Applications and Limitations in the Past

Graphene has been integrated with other materials to increase its strength and mechanical properties. Graphene has been utilized in the aerospace industry and nanotechnology applications. It has also found applications in batteries and superconductor applications. Along with this, graphene oxide has also been utilized as an additive in aircraft fuel for efficient burning and increased power production.

The major limitation in its applications includes its susceptibility to undergo rapid oxidation. The toxic characteristics associated with its implementation have always been a major concern. Apart from this, the financial constraints due to high costs associated with its production have been a hurdle in its mass production. However, graphene oxide can readily be obtained by oxidation reactions in a lab.

Although purification of water has been researched in the past, this novel approach is unique in that it has no side effects. The process of using graphene as a sieve for purifying water will surely help battle water shortage problems all over the world.

Methods

The method of the purification of seawater consists of many steps. The first one is the preparation of GO membranes. For this purpose, aqueous GO suspension is prepared by dispersion of mm-sized GO grains for 15 hours using bath sonication. To eliminate the multilayered GO flakes, the emulsion is centrifuged six times at 8000 rpm.

Following that, vacuum filtering is used to generate free-standing GO membranes with a thickness of 100 µm. The next step involved the interlayer spacing in GO laminates by synthesizing and storing GO membranes with various interlayer (IL) spacing. X-ray diffraction in 2θ range of 5° to 15° was performed for analysis of IL by Bruker D8 diffractometer.

After this, rectangular strips obtained from previous strips were glued and placed on top of each other. They were reinforced by an epoxy layer at the top and bottom for permeation experimentation. For the permeation experiment, clamping of membranes between O-rings was done and compartments were filled with equal volumes of salt solution and deionized water. Such experiments were carefully done in a temperature-controlled environment along with continuous magnetic stirring.

Research Findings

The research in the journal Nature showed that nanopores with diameters equivalent to or lower than the diameter (d) of hydrated ions are expected to have improved ion selectivity. The effective pore size of 9 in the swollen membranes (excluding the space filled by carbon atoms) was bigger than the average size of hydrated ions, limiting the potential applications of GO for size-exclusion based ion sieving.

The resultant interlayer spacing was determined by X-ray diffraction and ranged from 6.4 to 9.8 with RH varying from 0% to 100%. d 13.7 0.3 for GO laminates immersed in liquid water. All of these values were consistent with prior findings in which the variations in d were attributed to the sequential integration of water molecules into different locations between GO sheets.

Image Credit: Daniel Ramirez-Gonzalez/Shutterstock.com

As predicted, the ion quantity in the permeate container rose with time and feed solution concentration. With decreasing d, the penetration rates and cutoff diameter for salt permeation drop steadily over time. Even after five days, membranes with d 6.4 revealed no appreciable ion concentration in the permeate.

As mentioned before, experiments were performed at various temperature values. Permeation rates match the Arrhenius equation for both channel diameters, d = 9.8 and d = 7.9. E = 72 7 and 20 2 kJ/mol for K+ ion penetration across PCGO membranes with d 7.9 and 9.8, respectively.

The model of network for graphene capillaries was developed for measuring the permeation of water. The energy barrier E rises sharply with d 9 and is significantly higher for divalent ions than for monovalent ones. The obtained E are of the same order of magnitude as those discovered experimentally, indicating no salt ions pass through it.

Limitations and Challenges

The pore sizes from the experiment were less than the size of ions stopping them from passing through. However, it is a very difficult task. Tiny holes in the membrane must be drilled to make it permeable. However, if the hole is greater than one nanometer in diameter, the salts pass through it. To be helpful for desalination, a membrane with a highly homogeneous less-than-one-nanometer pore size is required. This is a difficult task.

Future Impact

The physical limitation of interlayer separation allows for the separation and purification of water molecules from ions, paving the way for the manufacture of low-cost membranes for desalination. The ultimate objective is to develop a filtering mechanism that can generate drinkable water from the ocean or wastewater while using very little energy.

In short, the research has successfully demonstrated the purification of water by graphene. According to the UN, water shortage is rising drastically and major countries are looking towards utilization of desalination to cope with this major concern. The process described in the research would surely turn out to be a game-changer in this regard due to its efficacy.

Further Reading: The Use of Graphene in Dentistry

References and Further Reading

Abraham, J., Vasu, K. S., Williams, C. D., Gopinadhan, K., Su, Y., Cherian, C., . . . Nair, R. R. (2017). Tuneable Sieving of Ions Using Graphene Oxide Membranes. Nature Nanotechnology. https://pubmed.ncbi.nlm.nih.gov/28369049/

Mauter, M. S., & Fiske, P. S. (2020). Desalination for a circular water economy. Energy and Environmental Science. https://pubs.rsc.org/en/content/articlelanding/2020/ee/d0ee01653e

Rincon, P. (2017, April 3). Graphene-based sieve turns seawater into drinking water. From BBC-Science: https://www.bbc.com/news/science-environment-39482342

Tanugi, D. C., & Grossman, J. C. (2012). Water Desalination across Nanoporous Graphene. Nano Letters. https://pubs.acs.org/doi/10.1021/nl301285

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.