Numerous industries make use of aluminum. These industries include construction, transportation and food as it forms alloys with a number of different materials. Its versatility and lightweight make aluminum and its alloys particularly good for industries where weight reduction is important, such as automotive and aerospace.

Yet, casting aluminum is far from easy. Carefully controlling the elements within the melt is crucial to ensure that the final material possesses the required properties. The most effective way of melt control is analysis with optical emission spectroscopy (OES).

However, not all OES instruments are considered equal. Particular care and attention are needed with aluminum as some of the elements must be managed within extremely low limits, meaning some analyzers may not detect the requisite values.

The new OE720 spark spectrometer from Hitachi High-Tech has been developed to deliver excellent performance at an accessible price point. This means that the OE720 can detect elements that typically require a specialist instrument, such as phosphorus and antimony, at low detection limits.

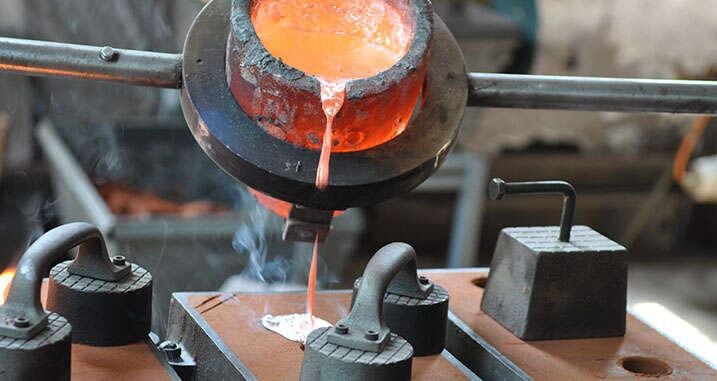

Image Credit: Hitachi High-Tech Analytical Science

Detection Limits of the OE720 for Elements Important to Aluminum Melt Control

The new optical system of the OE720 analyzer has been innovatively designed to deliver next-level optical resolution, and the CMOS detector technology guarantees that an extensive range of elements can be determined at extremely low limits.

In this way, phosphorus can be detected down to 20 ppm in near eutectic and hyper-eutectic aluminum-silicon alloys, and antimony, bismuth, lithium, strontium and sodium can be controlled, assuring manufacturers of optimal structural modification.

This high-performance capacity enables verification that the tramp elements P, Ca, Bi and Sb within the aluminum melt do not exceed the 120 ppm maximum combined total.

Performance of the OE720 for Key Aluminum Elements:

Source: Hitachi High-Tech Analytical Science

| Element |

Bi |

Ca |

Li |

Na |

P |

Sb |

Sr |

| Limit of the detection (ppm) |

5 |

1 |

1 |

1 |

20 |

10 |

1 |

Download the full application note

Technical Features of the OE720 that Improve Performance

The OE series features two models: the OE720 and OE750. Both models offer high performance across a complete spectrum of elements within metal. The OE720 will detect all non-gaseous elements within the melt, and the OE750 incorporates gas detection capability, which is not a requirement for aluminum analysis.

Both models gain significant advantages from these innovations:

- Ability to determine an extensive range of elements owing to a wavelength range of 174 - 670 nm (OE720) and 119 - 670 nm (OE750). With the additional capacity to expand the upper limit of the range to 766 nm for both models on request.

- Completely redeveloped optical system and advanced CMOS detector design offer extremely high optical resolution across the wavelength range, enhancing the detection limit capability of the instrument.

- Mid pressure system and new spark stand design to limit the amount of argon necessary and reduce power consumption by up to half. These enhancements help to significantly reduce operating costs when using the instrument 24/7.

- Sealed spark stand design and mid-pressure system provide exceptional stability and transparency and lower necessary maintenance requirements, thereby improving the uptime of the analyzer.

Hitachi’s Solution Package for Aluminum Foundries

Hitachi High-Tech has compiled a solution package for aluminum foundries with a special package price so that customers can cover the quality control throughout the entire process. The handheld LIBS Vulcan Optimum+ can be used for rapid non-destructive sorting of incoming goods, and the OE720 spark spectrometer can be used for melt control.

The combined purchase of these instruments could save up to $4,000.

This information has been sourced, reviewed and adapted from materials provided by Hitachi High-Tech Analytical Science.

For more information on this source, please visit Hitachi High-Tech Analytical Science.