The commercialization of lithium batteries has been the focus of manufacturers and researchers all over the world. This is due to the advantageous features of such batteries. New research has been successful in determining the optimum stacking pressure for these batteries.

Image Credit: petramalink/Shutterstock.com

Lithium Metal (Material) and its Limitations in Batteries

Various research projects have all concluded that lithium is the best material for battery anodes. Several types of research have been conducted to obtain Li deposition nearly identical to its original density value. The mechanical characteristics of Li metal have also been extensively researched.

However, a few limitations have also been observed. Since its foundations in 1976, effective rechargeable Li metal batteries have not yet been accomplished due to their poor Coulombic efficiency (CE) and safety hazards induced by potential dendrite development and inactive Li production.

Furthermore, because of Li's high reduction potential, the (electro)chemically produced solid electrolyte interphase (SEI) between the Li metal and liquid electrolyte renders electrolysis a kinetically sluggish solid diffusion process.

Lithium Batteries Industrial Utilization

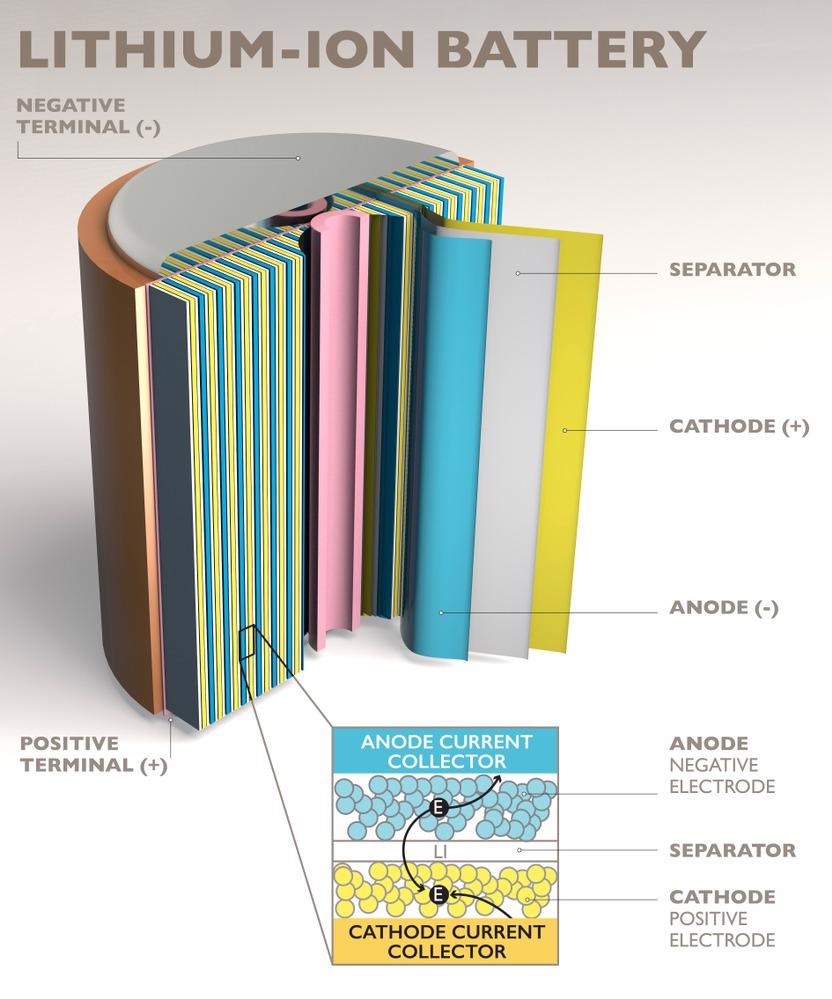

Because of the high power density and extended cycle life, lithium-ion batteries (LIBs) are widely utilized in portable electronics, electric cars, and long-term energy storage. Massive marine equipment and ships are also powered using Li-ion batteries.

Apart from this, solar power energy readily utilizes Li-ion batteries for solar panels owing to the fast and efficient charging and storage. Because of their long life, compact size, and lack of power loss due to self-discharge when the system is idle, rechargeable lithium batteries are perfect for remote surveillance systems. Hence, lithium-ion batteries have found their applications in almost all fields of life.

Limitations of Lithium-Ion Batteries

LIBs although are very efficient and useful, yet several limitations still exist regarding their utilization. A major one is its severe sensitivity to high temperatures and expensive costs associated with it. The entire manufacturing cost of these batteries is approximately 40% more than that of nickel-metal hydride batteries.

Along with this, protection is required to prevent overcharging of these batteries. The danger of explosion for such batteries in case of overcharging also exists. Although these limitations exist, the advantageous features of these batteries are prevalent over the disadvantages.

Latest Study of Lithium-Ion Batteries

Research in the journal Advanced Energy Matter proved that pressure less than the optimum value could lead to the deposition of lithium particles in a disordered fashion. This optimum pressure would help drastically in increasing the lifespan of the batteries as well as substantially increasing the performance.

The study by Mr. Wilkinson and his team involved the study of the impacts of stack pressure on Li/MoS2 prismatic cells. The novel study also proves this claim that stack pressure is essential for a rapid improvement in the life cycle of lithium-ion batteries.

Image Credit: Naeblys/Shutterstock.com

The steps involved 3D cryogenic ion beam-scanning electron microscopy, titration gas chromatography (TGC), cryogenic transmission electron microscopy (cryo-TEM), and molecular dynamics (MD) simulation.

The CE decreased from 92.5 percent at 1 mA/cm2 to 85.5 percent at 2 mA/cm2 at 0 kPa. The CE rose for all current densities when the stack pressure was slightly increased to 35 kPa, while the CE at 2 mA/cm2 climbed to 92 percent. The CE was increased to 98 percent, 97 percent, and 96 percent at 1, 1.5, and 2 mA/cm2 at 350 kPa, respectively. Increasing the stack pressure over 350 kPa will not enhance the CE anymore.

Furthermore, by raising pressure from 70 kPa to 350 kPa at a high current density of 4 mA/cm2 at room temperature, the average CE was enhanced from 98 percent to above 99 percent. The permeability and density of Li deposits produced at 70 kPa and 350 kPa were quantified using cryo-FIB 3D reconstruction. The thickness of the Li layer is estimated to be 3.677 m and 1.697 m when electroplating at 70 kPa and 350 kPa, respectively.

MD simulations were used to investigate the impact of pressure on the early spatial development of Li deposition. MD simulation demonstrated that stack pressure influences the temporal development of Li deposition by favoring lateral Li accumulation.

Further Reading: Impurities in Lithium Materials

Cryo-TEM was used to explore the effects of pressure on the SEI structure. At 70 kPa, the Li deposits have a hair's breadth structure, whereas, at 350 kPa, they have big-particulate morphological characteristics.

Impact on LIBs Consuming Industries

Modern research has successfully demonstrated that applying pressure on LMBs during battery cycling improves efficiency and stability, assisting in the resolution of this lifespan issue. Along with this, the optimum pressure was calculated and applied. Such steps would efficiently increase the lifecycle of the batteries.

This would revolutionize industries such as electronics, solar energy, and aerospace industries, etc. . Such unparalleled modulation of battery electrocatalytic activity using stack pressure is an important advance toward novel design guidelines and fabrication methods that will enable viable Li metal batteries and other metal anodes

Limitations of the Study

The current study is focused on lithium-ion batteries. The study is focused on optimum pressure for increasing lifetime and efficiency without the effective measurement of optimum temperature. For Li-ion batteries, high temperatures are very dangerous. Therefore, the effective optimum temperature should also be incorporated.

From the research, it is known that the optimum pressures can be used to adjust the lithium nucleation and strong adhesion between the molecules. The optimum pressure was found to be 350 kPa. This would surely revolutionize the properties of lithium-ion batteries and remove the hurdles in their rapid commercialization.

References

Adams, B. D., Zheng, J., Xu, W., & Zhang, J. G. (2017). Accurate Determination of Coulombic Efficiency for Lithium Metal Anodes and Lithium Metal Batteries. Advance Energy Matter, 1-11. https://onlinelibrary.wiley.com/doi/abs/10.1002/aenm.201702097

Fang, C., Lu, B., Pawar, G., Zhang, M., Cheng, D., Chen, S., . . . Meng, Y. S. (2021). Pressure-tailored lithium deposition and dissolution in lithium metal batteries. Nature Nanotechnology. https://www.nature.com/articles/s41560-021-00917-3?proof=t+target%3D

Fang, C., Wang, X., & Meng, Y. S. (2019). Key Issues Hindering a Practical Lithium-Metal Anode. Trends Chem, 152-158. http://smeng.ucsd.edu/wp-content/uploads/Key-Issues-Hindering-a-Practical-Lithium-Metal-Anode.pdf

Loui, A. J. (2019). Exploring the Impact of Mechanical Pressure on the Performance of Anode-Free Lithium Metal Cells. J. Electrochem. Soc, 1291-1299. https://www.semanticscholar.org/paper/Exploring-the-Impact-of-Mechanical-Pressure-on-the-Louli-Genovese/deba4d04e7d724174d3fec257271cacbdbc4a2bb

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.