The K3® IS camera is able to deliver a large field of view, rapid, continuous data capture and, simultaneous low-dose imaging via real-time electron counting.

The model 652 furnace-type holder has been specifically designed to enable the direct observation of microstructural phase changes, catalysis, growth, nucleation, and dissolution processes in 3 mm transmission electron microscope (TEM) samples at raised temperatures.

Context

MoS2 offers many benefits to applications that centralize the role of void or pit formation in their resulting material properties. The nucleation and growth of pits may be impacted by adventitious carbon during real-world synthesis. This is a thin layer of carbon that is typically present on materials that have been exposed to air.

In-situ TEM represents one of the most useful techniques for the study of adventitious carbon layers and investigations into its behavior at high temperatures. It can also be used to look at adventitious carbon layers’ impact on pit formation in MoS2.

Low-voltage, low-dose continuous imaging may be employed alongside infrequent high-resolution imaging to examine these processes while ensuring that the electron beam does not impact the sample to any great degree.

Materials and Methods

In the example presented here, a Titan ETEM was used to image a MoS2 sample. This was done at 80 kV to minimize beam damage. A model 652 heating holder was used to increase the sample’s temperature from room temperature to 300 °C at a rate of 10 °C per minute.

A K3 IS camera was used to record in-situ TEM video over the whole ramp, resulting in the production of a counted video almost 30 minutes long. This video successfully captured a large area (595 x 423 nm) comprised of 1 Å pixels, allowing more than 20 carbon nanoparticles to be simultaneously observed.

The K3 IS camera offers a distinct combination of high detective quantum efficiency (DQE) and counted acquisition. This enables a low dose rate of 8 e-/Å2 per second, further minimizing beam damage.

The video – of more than 8,000 frames – led to a total dose of 13200 e-/Å2. This is equivalent to a handful of single atomic-resolution TEM images captured using a conventional TEM camera.

Figure 2c shows a OneView image1 which features a total dose of 3200 e-/Å2 as part of a 0.32-second exposure.

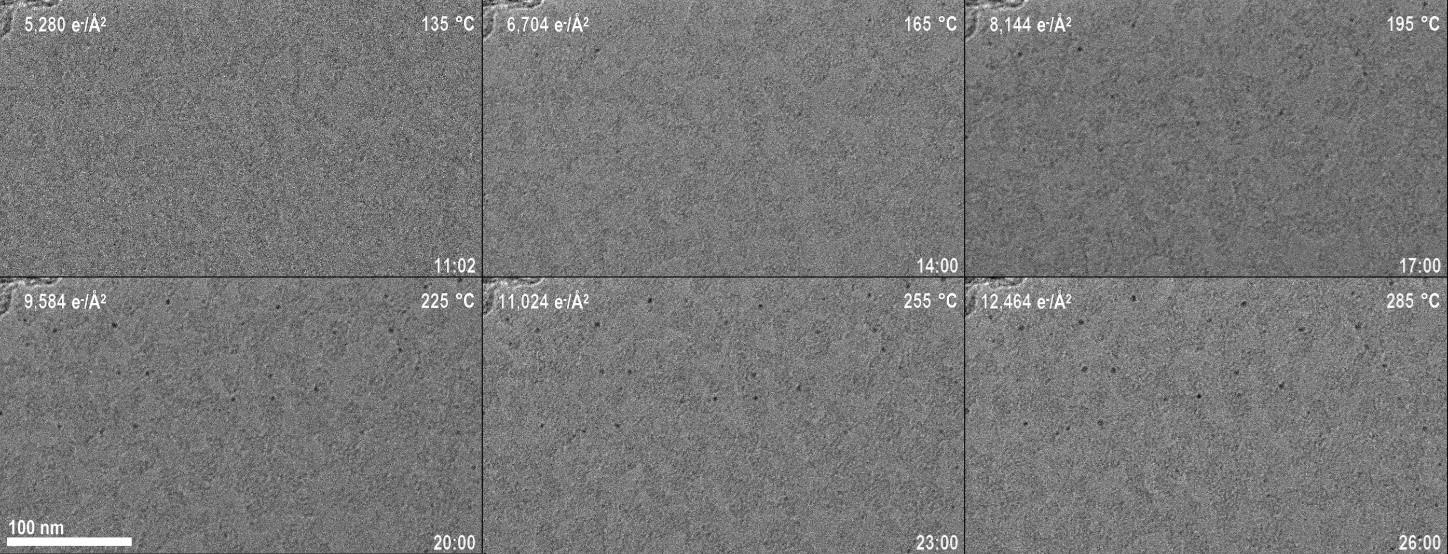

Figure 1. Frames from a ~30 min low-dose in-situ video showing formation of carbon nanoparticles during heating in a Gatan heating holder. Note that this sequence starts 11 minutes into the video, but most particles first appear between 14 and 17 minutes (165 – 195 °C). This indicates that heating and not the electron beam was primarily responsible for the carbon agglomeration. The dose rate during acquisition was just 8 e-/Å2/s. Each frame shown here is a sum of 10 original frames, with 16 e-/Å2 total dose. Image Credit: Gatan Inc.

Summary

The original video’s framerate was 5 frames per second (fps) as it was saved to disk, but the K3 IS camera was able to capture and count raw frames internally at a rate of 1500 fps.

It was noted that the video’s first 11 minutes were unremarkable and, therefore, this footage was left unprocessed. This left a residual dataset of 4,913 frames. Each frame was 5760 x 4092 pixels in size, accounting for a total of 107 GB of data.

Following acquisition, data was binned by a factor of 4 before being drift corrected, cropped and summed at every 10 frames to generate a final video dataset.

This final dataset – saved in *.dm4 format – was comprised of 492 frames, each 812 x 444 pixels in size, accounting for a total of 790 MB of data.

The dataset was processed using the Gatan Microscopy Suite® (GMS), with the *.mp4 video of this processed dataset accounting for a total of 93 MB - a 99.9% reduction in data volume. Figure 1 shows selected frames from this video.

As the K3 IS camera is able to operate at 80 kV accelerating voltage with a low dose rate, it was possible to generate the in-situ video of MoS2 with minimal beam damage.

Heating the sample to 300 °C using a Gatan heating holder was key to facilitating the clear study of adventitious carbon agglomeration into carbon nanoparticles.

By processing more than 100 GB of data using GMS, it was possible to reduce this to a 93 MB *.mp4 video.

The data demonstrates that the majority of particles initially appear at around 170 – 180 °C. A number of other in-situ observations were made on the same TEM. Conducting these observations in the presence of O2 gas verified that these particles were linked to the formation of pits in the MoS2.1

Reference

- Park, S. et al. Effect of Adventitious Carbon on Pit Formation of Monolayer MoS2. Adv. Mater. 2003020 (2020) doi:10.1002/adma.202003020.

This information has been sourced, reviewed and adapted from materials provided by Gatan Inc.

For more information on this source, please visit Gatan Inc.