The Model 628 is a furnace-type holder that has been specifically designed to facilitate the direct observation of microstructural phase changes, growth, catalysis, nucleation, growth, and dissolution processes at high temperatures in 3 mm TEM samples.

Context

Heterogeneous catalysis is a critical process in a range of clean energy technology applications, for example, reducing soot emissions. Heterogeneous catalysis sees reactants transformed into products on a solid catalyst material’s surface.

Much of the ongoing development of catalyst materials is focused on nanoparticles (NP) due to their significant surface-to-volume ratio. Recent studies into the application of Ag for the oxidation of soot and other carbonaceous materials have yielded promising results.

The study presented here seeks to explore the atomic structure of Ag nanoparticle active sites for carbon oxidation through the use of multi-walled carbon nanotubes (MW-CNT) - a model carbonaceous material.

Materials and Methods

Gatan’s model 628 heating holder was employed inside an aberration-corrected environmental TEM (AC-TEM) in order to achieve a high temperature in an O2 environment.

No video recording took place as it was essential to keep the electron beam exposure as low as realistically possible.

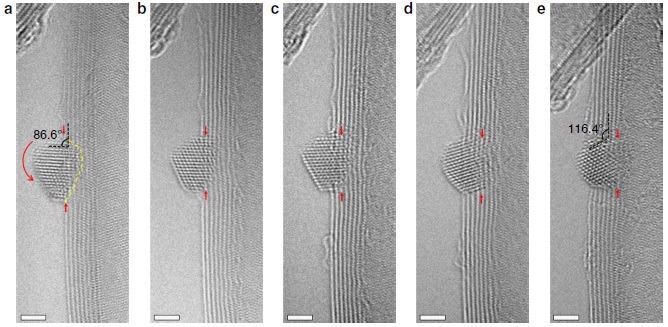

An UltraScan® camera was used to acquire single-frame images. The sample was set at 250 °C, but there was no oxygen present to minimize any risk of ionization damage. Figure 1 features a series of these images.

Figure 1. Series of AC-ETEM images during nanotube oxidation. The oxidation reaction was conducted at 250 °C in 2 mbar O2 images were acquired after: (a) 0 s, (b) 300 s, (c) 600 s, (d) 900 s, and (e) 1,800 s. The two dashed black lines in a) mark the angle between the Ag NP/MW-CNT system, which was used to monitor the rotation of the Ag NP. The curved red arrow denotes the rotation direction, and the yellow dashed line marks the contact interface between the Ag NP and the MW-CNT. Scale bars are 2 nm. Small red arrows indicate the depth to which the oxidation has reached. The turnover frequency of the Ag NP sites on this single particle could be directly determined from these images. Yue, Y., Yuchi, D., Guan, P., Xu, J., Guo, L., Liu, J., 2016. Atomic scale observation of oxygen delivery during silver-oxygen nanoparticle catalyzed oxidation of carbon nanotubes. Nature Communications 7, 12251. doi:10.1038/ncomms12251. Image Credit: Gatan Inc.

Summary

A model 628 heating holder in an aberration-corrected ETEM successfully enabled the careful in-situ observation of Ag nanoparticles catalyzing the oxidation of carbon nanotubes.

The acquisition of high-resolution images of the catalyst particle at numerous points in the tube’s oxidation allowed the turnover frequency for this single nanoparticle to be quantified.

Using these observations as a guide, first-principles simulations have indicated the presence of a Mars-van Krevelen type mechanism, whereby oxygen is dissociated on the Ag surface, diffusing through the Ag NP to eventually reach the MW-CNT surface.

This information has been sourced, reviewed and adapted from materials provided by Gatan Inc.

For more information on this source, please visit Gatan Inc.