To optimize the surface of multiphase Al alloys for successful EBSD analysis, the EDAX Pegasus Analysis System with Octane Elect, Velocity™ Super and APEX™ 2.0 Software and the Gatan PECS™ II were used.

For the acquisition of legitimate EBSD orientation measurements, the true structure of a specimen must be continuous to the surface with no distortions. Thus, it is essential to minimize any surface contamination and damage introduced during specimen preparation.

On soft materials, such as aluminum, using mechanical polishing to prepare the sample is extremely complex without introducing a thin distorted surface layer that conceals the real microstructure.

When secondary phases with various polishing responses are introduced, simultaneously producing a suitable specimen surface for all phases is even more of a challenge. Broad beam ion milling offers a way to eliminate the distorted layer from the entire surface while minimizing the risk of any additional damage caused by mechanical contact.

Materials and Methods

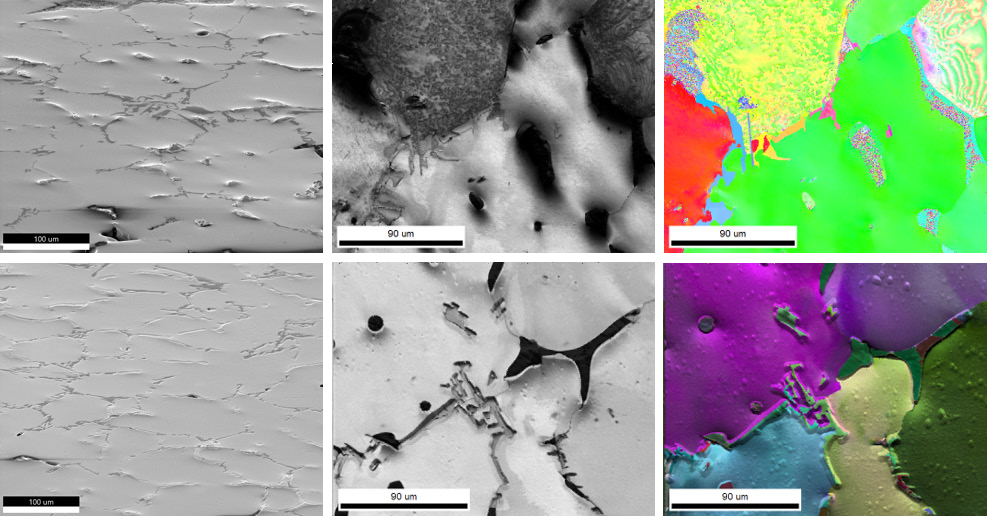

A multiphase Al alloy sample with Si, Cu, Fe and Sn containing phases is analyzed by EBSD mapping once routine mechanical polishing has been performed. Orientation data could be acquired from the majority of areas. However, some grains demonstrate preparation artifacts, while specific intermetallic phases do not yield indexable patterns at all (Figure 1, top row).

Once the analysis was completed, the sample was placed in the PECS II and milled using 4 kV Ar ions at a low incident angle of 3˚ for 20 minutes. The low angle was chosen for the removal of the surface topography that had built up around the secondary phase particles.

The eventual surface was smooth, and thus EBSD patterns could be acquired from all phases for total surface analysis (Figure 1, bottom row).

Figure 1. (top row) (left) Secondary electron image of polyphase Al alloy after mechanical polishing (tilted sample). Some phases did not polish well and stand out from the surface. (center) EBSD image quality (IQ) map illustrating that no diffraction patterns could be collected from the protruding grains (black areas). Two grains at the top show an intricate substructure, which is an artifact caused by mechanical polishing. This substructure is also apparent in the inverse pole figure (IPF) map (right). (bottom row) (left) Secondary electron image after ion milling (tilted sample). Most topography has been removed, and all grains now produce indexable EBSD patterns. The artificial substructures have been removed and the true grain structure is displayed in the IQ and IPF maps (center, right). Image Credit: Gatan Inc.

Summary

Through the application of broad beam ion milling, Al specimens comprised of multiple phases with a diverse range of polishing responses can be prepared successfully for EBSD analysis.

The ion milling guarantees a damage-free, clean sample surface and optimizes the electron diffraction signal from all phases, irrespective of their polishing resistance.

This information has been sourced, reviewed and adapted from materials provided by Gatan, Inc.

For more information on this source, please visit Gatan, Inc.