In recent years, the fastest growing segment of the electron microscopy market has been Table-top SEMs. As these tools continue to gain wide acceptance, users are often required to image non-conductive samples.

Imaging non-conductive samples can be challenging as these samples are subject to a phenomenon referred to as charge electrification, or simply, charging. Charge electrification phenomenon results from the build-up of negative charges on the sample when irradiated by the electron beam. If the sample is non-conductive (or poorly conductive) these charges can cause image distortion and contrast irregularities.

To prevent sample charging, several methods can be used. The most common method is to coat the sample with a thin conductive film, typically carbon or metal. While this method improves imaging, it also changes the chemical composition on the surface of a sample. In addition, the user must consider coating thickness and particle size to ensure satisfactory results. Finally, some samples cannot be changed or adulterated and must be imaged in their natural state. For these types of samples we can try to image them at a lower accelerating voltage to minimize charging effects. While this method can be effective in FE-SEM, it works less well in a typical Tungsten SEM

An alternative solution to this problem is the use of low vacuum mode (LV mode). LV mode enables you to get images simply without pretreatment or coating in almost any environment. LV mode works by putting the sample chamber in a low-vacuum state, while simultaneously keeping the column and electron source in a high vacuum state. The interaction between the air in the chamber and incident and reflected electrons result in the production of positive ions, changing the charge balance of the sample and neutralizing the negative charges accumulated on the surface of the sample.

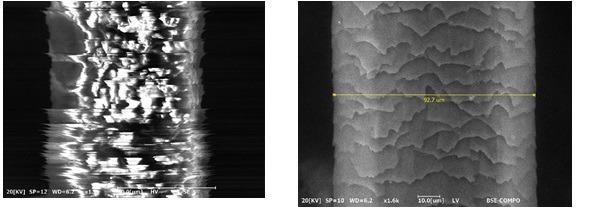

Figure 1. Image of hair at HV mode(left) / image of hair at LV mode(right). Image Credit: COXEM Co. Ltd.

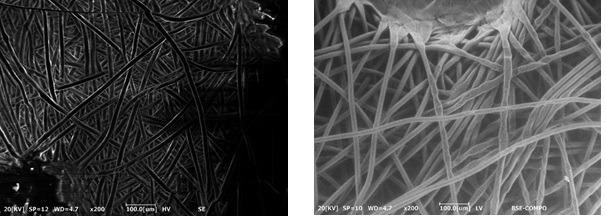

Figure 2. Image of a mask at HV mode(left) / image of a mask at LV mode(right). Image Credit: COXEM Co. Ltd.

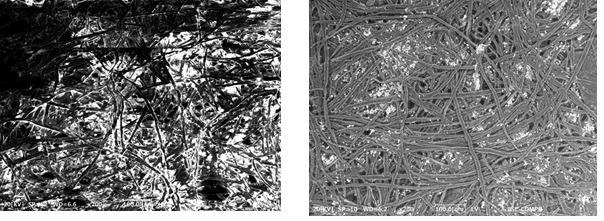

Figure 3. Image of paper at HV mode (left) / image of paper at LV mode (right). Image Credit: COXEM Co. Ltd.

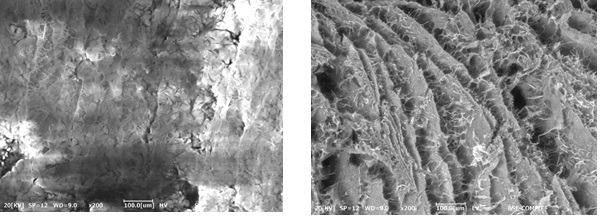

Figure 4. Image of a collagen scaffold at HV mode (left) / image of a collagen scaffold at LV mode (right). Image Credit: COXEM Co. Ltd.

The above figures show a comparison of images which were obtained from HV mode and LV mode on the EM-30N. In the same sample, while in HV mode, the image appears to be distorted due to charge electrification phenomenon, while in LV mode the image is clean and distinct. In particular, in the case of fiber samples with complex structure, partial charge electrification can occur because coating is poor and non-uniform in areas which are located far from the surface. By using LV mode, you can get clean images regardless of the structure of a sample.

COXEM's Table-top SEM (EM-30N) offers a choice of either HV or LV modes. By selecting LV mode from the GUI, the mode will change automatically and you can get images of non-conductive samples without coating or using special sample holders. Furthermore, COXEM has developed Variable Pressure (VP) mode so the user can determine the optimum degree of vacuum for each individual sample. This gives you the flexibility to get images of various non-conductive samples such as biological materials, damp or dirty samples, and any sample that would not be able to be imaged in their natural state due to the effects of high vacuum. VP mode will also be available in COXEM’s newest addition to their table-top line, the EM-50.

With the addition of Low Vacuum and Variable Pressure modes, COXEM has been able to extend the applications of their table-top systems to areas that up to now were served by relatively expensive and complex full-size SEMS. For more information on the complete line of COXEM Table-top SEMs, including variable pressure systems, contact your local COXEM representative.

This information has been sourced, reviewed and adapted from materials provided by COXEM Co. Ltd.

For more information on this source, please visit COXEM Co. Ltd.