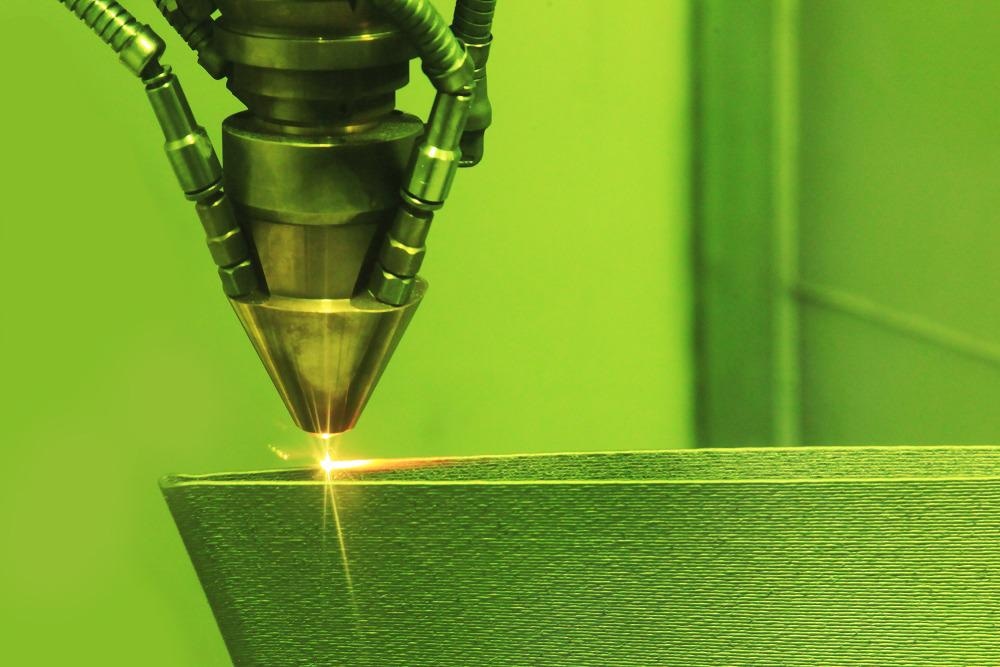

This article considers laser-based 3D printing, or additive manufacturing, looking at different types of lasers in the fabrication process.

Image Credit: sspopov/Shutterstock.com

Laser-based 3D printing

The last decade has witnessed a huge development in additive manufacturing (AM) or 3D printing when compared with its counterpart, subtractive manufacturing. AM enables rapid prototyping, ease of customization, replication of complex parts, waste minimization, high energy efficiency, inventory stock reduction, part and product flexibility, and reliability. The major issue that limits AM to only prototyping is its high cost of production and the decrease in precision with an increase in printing speed.

Nevertheless, direct energy deposition type AMs are more suitable for precision fabrication because it is easier to regulate the energy flow rather than material flow. Since the advent of the concept of 3D printing, laser-based direct energy deposition type AM has earned its place in the global competitive market due to the precision that the lasers offer over the other AM processes such as hot material extrusion/fuse deposition modeling, binder jetting, liquid material jetting, and sheet lamination.

Laser is most commonly used in vat photopolymerization, direct laser writing (DLR), selective laser melting (SLM), and selective laser sintering (SLS)/powder bed fusion AM processes.

What is Femtosecond Laser?

Femtosecond (fs) laser is a class of ultrafast/ultrashort pulse laser in which the durations of laser pulses vary from a few fs (10-15 s) to hundreds of fs. Such short-duration pulses are obtained through mode-locking, i.e. fixing the phase relationship between the longitudinal modes of the resonant cavity.

What is a Mode-locked Laser?

All lasers have a range of frequencies or bandwidth instead of a single wavelength or frequency. The operational bandwidth of a laser is determined by the nature of the gain medium and longitudinal modes of the optical resonance cavity (ORC).

Coming to the basic structure of a pulse laser, a gain medium is sandwiched between two parallel mirrors, which is called an ORC. A single beam of light bounces between these two mirrors and repeatedly passes through the gain medium. The beam of light interferes with itself at specific points inside the gain medium, either constructively (i.e. amplifies) or destructively (i.e. cancels out) based on the phase difference.

The constructive interference results in the formation of standing waves or modes. These standing waves can be segregated into discrete frequency ranges, known as longitudinal modes of the ORC. These excited/resonated longitudinal modes are the core bandwidth of the high-intensity laser beams.

Furthermore, an ORC can have multiple longitudinal modes, in which one or multiple modes can be excited. Titanium (Ti)-doped sapphire (Ti:sapphire) laser has 128 THz bandwidth that can support up to ~250,000 longitudinal modes. If the phase difference between a large number of excited longitudinal modes can be fixed to cause constructive interference or resonance, it will generate a short-duration laser pulse. The wider the mode-locked bandwidth, the shorter the pulse duration of the laser. Moreover, the pulse duration also depends on the shape of the pulse.

There are two types of mode-locking, i.e., active and passive. In active mode-locking, an external modulator is placed inside the ORC that produces a signal that facilitates phase mode-locking. Meanwhile, in the case of passive mode-locking, no external signal is used, rather a saturable absorber is placed inside the ORC that selectively absorbs the low-intensity lights and transmits high-intensity lights.

Ultrafast/Ultrashort Pulse Laser Vs Continuous Wave Laser

When the electrons of material are excited above the bandgap, they quickly relax after radiating the excess energy, which is a potential loss.

This excitation duration before relaxation varies from a few nanoseconds (ns) to several microseconds (µs). In the case of fs laser, the pulse duration and the in-between interval are so short that the excited electrons do not get enough time to relax, which results in the accumulation of heat. Thus, fs lasers can achieve a temperature up to 6000 ℃, which is enough to melt high melting point materials such as tungsten (melting point = 3422℃) and ceramics.

Moreover, the peak intensity of the fs laser is almost equal to its average intensity; this leads to high penetration depth, less thermal diffusion, and faster fabrication speed. Meanwhile, continuous wave (CW) lasers have a broader intensity distribution and more thermal diffusion. This leads to undesirably larger thermal penetration and the formation of heat-affected zones (HAZs). Due to large grain size variation and the presence of microcracks, HAZs are sensitive to mechanical failures. Hence, they often require post-process thermal treatments.

Latest Research

An Fs pulse laser can be used for surface texturing. It was used to create periodic structures on black silicon with nano- and microsize features. The surfaces of solar panels can be altered by femtosecond lasers to increase solar cell efficiency.

Moreover, a Ti: Sapphire fs laser has been used to study the formation of nanostructures on the surface of tin (Sn), and bond strength and structural modifications of silicon, TiO2, and graphene. It was also used for tuning the hydrophobicity of polydimethylsiloxane (PDMS) surfaces, and nanograting and micromachining of very small optical fibers. It is useful in 3D photonic circuit fabrication as it is capable of permanently altering the refractive index of circuits buried beneath the surface of transparent glasses and polymers.

Conclusions

Fs lasers have paved the way for high precision 3D printing of metal, glass, polymers, ceramics, and many more. Moreover, their ability to process high melting point materials is also a big achievement. High energy efficiency, the reduction of post-processing treatments, high depth of penetration, and faster processing speed, make fs lasers an ideal source of energy for 3D printing.

References and Further Reading

Kaligar, A.B., Kumar, H.A., Ali, A., Abuzaid, W., Egilmez, M., Alkhader, M., Abed, F., Alnaser, A.S. Femtosecond Laser-Based Additive Manufacturing: Current Status and Perspectives. Quantum Beam Sci. 2022, 6, 5. https://www.mdpi.com/2412-382X/6/1/5

3DPrint.com. (2021, October 19). Femtosecond Lasers for Use in Additive Manufacturing. 3DPrint.Com | The Voice of 3D Printing / Additive Manufacturing. https://3dprint.com/185885/femtolasers-in-additive-mfg/

Paschotta, R. (2021, July 27). Femtosecond Lasers. 2022 RP Photonics Consulting GmbH. https://www.rp-photonics.com/femtosecond_lasers.html#:%7E:text=A%20femtosecond%20laser%20is%20a,which%20also%20include%20picosecond%20lasers)

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.