The present article discusses aluminum coating with silazane and other metals through laser treatment. The resulting silazane-coated aluminum substrate enhances hardness over conventional processes and is suitable for wear protection.

Image Credit: KULLAPONG PARCHERAT/Shutterstock.com

The stiffness and specific strength of aluminum in its pure form or in alloys make it suitable to be employed as a potential raw material to fabricate structural components. However, the lifetime of aluminum is reduced due to its low surface hardness and wear resistance. Although ceramization in the furnace using precursor-based coating is the most suitable method to enhance stiffness, its application is limited to high-temperature resistant substrates.

Surface Coating of Aluminum

High specific strength and stiffness are the prerequisites for designing lightweight structural components in the aerospace and automotive industries. Among a wide range of materials, aluminum and its alloys meet this criterion.

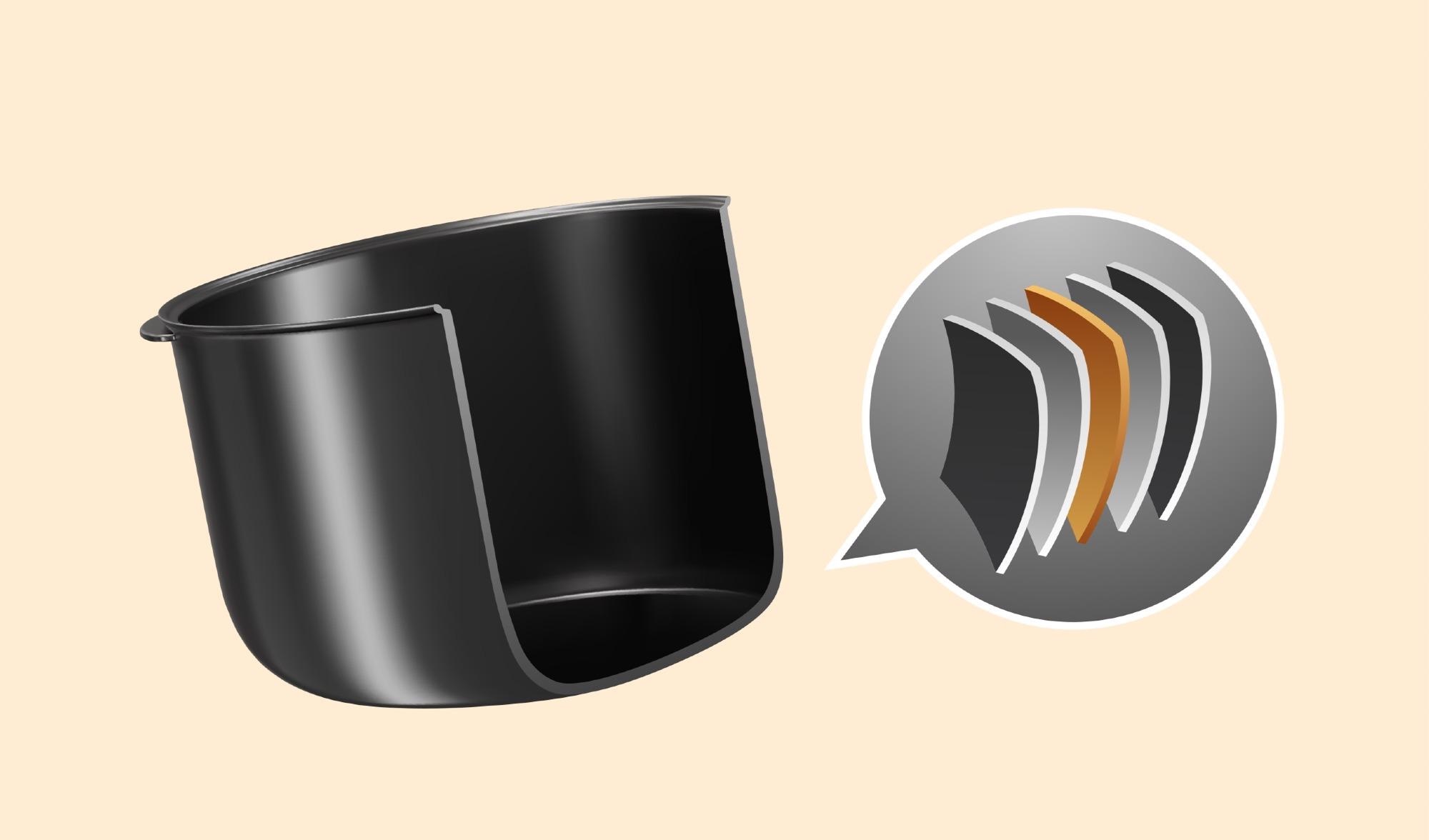

Although the surface coating is a cost-efficient and effective method to enhance the wear resistance and surface hardness of aluminum, it has to be coated at temperatures lower than 200 degrees Celsius to prevent its degradation. Few coating methods used include physical vapor deposition (PVD) processes. Nitrides of titanium (TiN) and chromium (CrN) are commonly coated on aluminum. While PVD coating is thin-layered, thermal spraying results in a thick and wear-resistant coating.

Polymer-derived ceramic (PDC) technology is an alternative technology to generate ceramic coatings that are hard and heat-resistant. PDC technology is a facile coating method that can be applied by spraying, spin-coating, dipping, or using a doctor blade.

Silazane Coating on Aluminum

In a study in the journal Ceramics International, the authors reported ceramic-coated aluminum via laser treatment. The ceramic coating consisted of 3 mol% yttria-stabilized zirconium oxide (ZrO2) and aluminum fillers. The ZrO2 filler increases the coating thickness and improves mechanical properties. Compared to other ceramics, ZrO2 has a high coefficient of thermal expansion (CTE), thus reducing the thermal mismatch between the coating and substrate. The addition of aluminum flakes increases the laser absorption and improves the conversion of laser radiation into the coating surface. Moreover, aluminum is a low-melting component that reduces the stress during the coating system’s solidification.

The authors anticipate that the investigated laser pyrolysis of the coating system has the potential for wear resistance on low-melting substrate materials like aluminum. Due to the short interaction time and selective pyrolysis with laser radiation, this approach allows substrate coating without any thermal damage or melting. Further, this process offered a low-cost method for applying the ceramic coating on a high-temperature sensitive substrate with low wear and corrosion resistance.

Related Studies

In recent work published in Nanotechnologies, the authors processed the aluminum alloy’s surface with multifunctional coatings with hierarchical roughness combining micro- and nano-texture. They showed that after the chemisorption of fluorosilanes on aluminum alloy, the coated alloy had superhydrophobic properties which persisted under mechanical load or ultraviolet radiation. Further, the coating was shown to have self-healing properties on long-term structural damages.

In another work reported in the journal ACS Applied Materials and Interfaces, the fabrication of superhydrophobic oxidized surfaces of aluminum alloys with enhanced resistance to pitting corrosion in sodium chloride solutions was discussed. This coating has prospective applications in the automotive industry, shipbuilding, aviation, construction, and medicine. The coating method was based on nanosecond laser surface treatment followed by a hydrophobic agent’s chemisorption to achieve the superhydrophobic state of the alloy surface. Further, the electrochemical and wetting experiments showed that the superhydrophobic state of the metal surface inhibited the corrosion processes in the chloride solution for a few days.

Image Credit: Rolling Stones/Shutterstock.com

Another recent study published in the Journal of Thermal Spray Technology demonstrated a new two-stage approach to the deposition of high-entropy alloy coatings on an aluminum substrate. In the first stage, they coated a 2.5 mm thick composite precursor coating deposited on the aluminum substrate by cold spray using two mixtures of five metal powders. In the second stage, the authors performed laser melting of the 500-1000 µm layer at the top surface of the composite coating. The microstructure analysis of the fabricated metal revealed good element mixing in the melting pool during laser melting.

Conclusion

In conclusion, photon-driven material manufacturing with a light beam and laser-aided modification has gained considerable interest in basic research. As laser processing is a sensitive process, it requires stringent control of lasing parameters. The laser-aided surface modification improves the mechanical properties and suppresses the corrosion of aluminum and its alloys. Further, the addition of ceramic particulates controls the evolution of microstructure.

Notably, this surface modification has the highest potential for repair and maintenance applications in biomedical, automobile, aero engines, machine tools, oil drilling, and process industries.

More from AZoM: What is Femtosecond Laser-Based 3D Printing?

References and Further Reading

Horcher, A., Tangermann-Gerk, K., Krenkel, W., Schafföner, S., & Motz, G. (2022). Advanced ceramic coatings on aluminum by laser treatment of filled organosilane-based composites. Ceramics International. https://www.sciencedirect.com/science/article/pii/S0272884222015176

Sova, A., Doubenskaia, M., Trofimov, E., & Samodurova, M. (2022). Deposition of High-Entropy Alloy Coating by Cold Spray Combined with Laser Melting: Feasibility Tests. Journal of Thermal Spray Technology, 1-17. https://link.springer.com/article/10.1007/s11666-021-01300-0

Sataeva, N. E., Emelyanenko, K. A., Domantovsky, A. G., Emelyanenko, A. M., & Boinovich, L. B. (2020). Laser Treatment of Aluminum Alloys for Fabrication of Weather-Resistant Superhydrophobic Coatings. Nanotechnologies in Russia, 15(2), 141-145. https://link.springer.com/article/10.1134/S1995078020020172

Boinovich, L. B., Emelyanenko, A. M., Modestov, A. D., Domantovsky, A. G., & Emelyanenko, K. A. (2015). Synergistic effect of superhydrophobicity and oxidized layers on corrosion resistance of aluminum alloy surface textured by nanosecond laser treatment. ACS applied materials & interfaces, 7(34), 19500-19508. https://pubs.acs.org/doi/full/10.1021/acsami.5b06217

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.