Cutting-tool development has seen a massive increase in recent years because of modern machining technology. This advancement significantly improves the manufacturing of mechanical products that require threaded parts for precise and quick assembly.

Usually, these threads are created using a cutting or shaping tap during the component’s final assembly stage.

Internal threading is a massively complicated operation in which threaded material, metalworking fluid, and tapping tool properties must all be tuned to ensure quality and consistency.

The Bruker UMT TriboLabTM tapping torque test rig is intended to provide both precise analysis of process performances and fast monitoring of tapping process parameters.

Setting Up a Tapping Torque Test

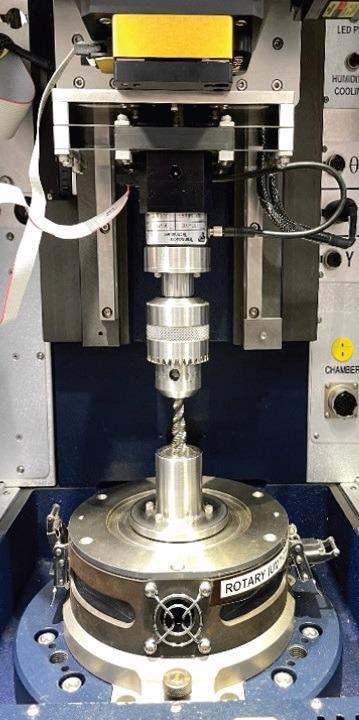

Figure 1 shows a tapping torque test setup made up of a UMT TriboLab with a high-speed rotary drive, a torque sensor, and a tapping torque kit. In a typical test, a workpiece pre-drilled with an 8.5 mm hole is added to the sample holder while an uncovered high-speed, size 10 steel tapping tool is introduced into the rig’s chuck holder.

Figure 1. Tapping torque with lower rotary drive kit on the UMT TriboLab. Image Credit: Bruker Nano Surfaces

The workpiece’s hole is then filled with approximately 5 mL of metalworking fluid (MWF) as a coolant and lubricant. In this study, the tapping accuracy and precision were improved with the synchronism feature between the machine rotation and feed motion.

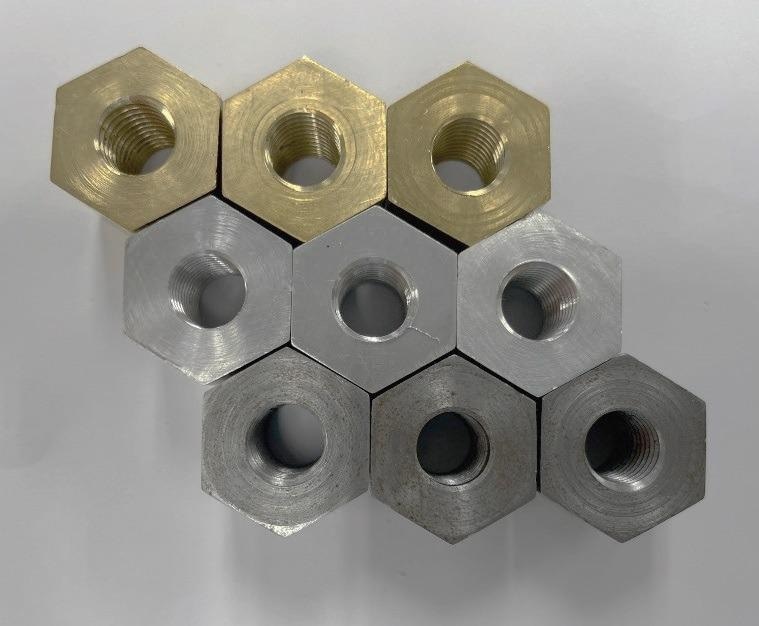

Three distinct forms of pre-drilled hex blanks (6061-T6 aluminum, C360 brass, and 1215 steel) were tapped to demonstrate the rig’s performance (Figure 2). To lubricate the tapping procedure, a commonly produced heavy-duty MWF was used with no further dilution. Table 1 lists the parameters of the examination.

Figure 2. Tapped nuts after tapping torque test. Image Credit: Bruker Nano Surfaces

Table 1. Test Parameter. Source: Bruker Nano Surfaces

| Description |

Values |

| Spindle speed (rpm) |

60 |

| Feed rate (mm/sec) |

1.5 |

| Hole depth (mm) |

17.5 (through hole) |

| Hole diameter (mm) |

8.5 |

| Tapping tool |

M10x1.5, HSS, chip clearing |

| Lubricant volume (ml) |

5 |

| Workpiece material (nut blank) |

C360 brass |

| 6061-T6 aluminum |

| 1215 steel |

| Workpiece dimension (mm x mm) |

8.5 x 17.50 |

For every test, the tapping operation was done five times with a different workpiece. The system’s software supplied real-time torque, friction coefficient, tap depth, and multi-channel data collecting to make determining tapping torque efficiency simple.

Tapping Torque Test Methodology

In this work, the test methods and assessment strategy were modified from two normative tapping torque test standards: ASTM D5619 00 (2011) and ASTM D8288 19.2. In short, an M10 cutting tap is threaded into the inside of a nut blank while the machine spins in the other direction. The torque sensor in the system collects the resulting torque readings at the same time.

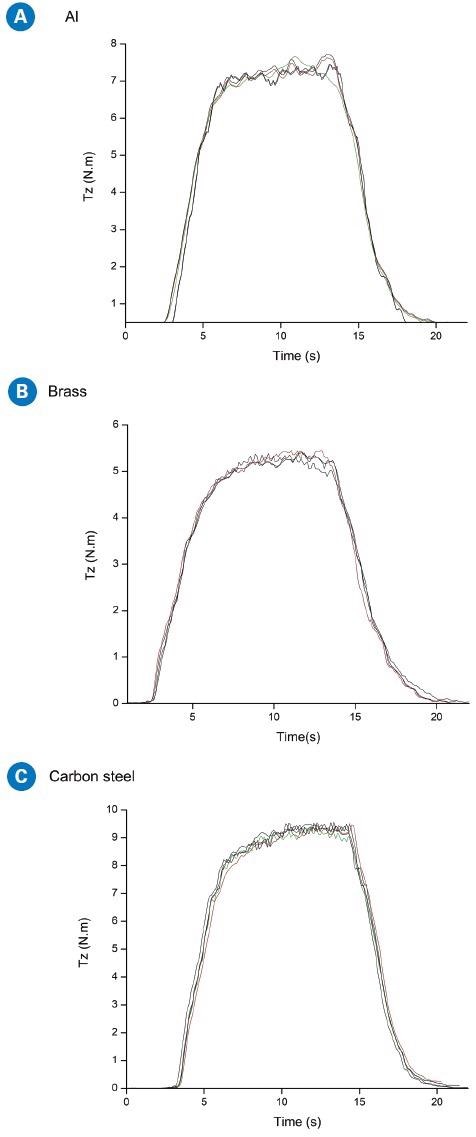

Figure 3 depicts the torque profiles of three metals with the large shear modulus (80 to 26 GPa) and hardness variances (Brinell hardness 95 to 167). This makes up the majority of popular manufacturing applications, such as roll threading and knurling with brass, aircraft or marine fittings with T6 aluminum, and rod rolling or wire with 1215 steel.

Each item was tested five times to gather statistics and assure the accuracy of the gathered information.

Figure 3. Torque profiles for three metals: (a) Aluminum: (5.41+/-0.03) N.m.; (b) Brass: (7.40+/-0.05) N.m.; (c) Steel: (9.48+/-0.06) N.m. Image Credit: Bruker Nano Surfaces

Tapping Torque Test Results

The torque values for the three types of threaded nuts ranged from 5.4 Nm to 9.48 Nm. The 6061-T6 aluminum, which provided the lowest torque value among the three alloys, had the best machinability based on these results.

Due to its 50% higher hardness and three-fold higher shear modulus than brass or aluminum, the 1215 steel with the greatest torque value had weaker machinability. Ultimately, the tapping torque test rig on the UMT TriboLab proved to be very reproducible, with dispersion well under 1%, fully meeting the ASTM D5619 approval criteria.

Aside from analyzing the efficiency of the cutting tap as reported in this study, a similar method could be used to analyze forming tap. This arrangement is appropriate for wide screening over tapping tools, lubricant/cooling fluids, and machined materials because of the high precision and low time to result.

Threading conditions can be altered in real-time to quickly converge toward the ideal machining conditions and components. Due to UMT TriboLab’s modularity, lubricant function can be easily examined using the 4-ball setup, and coating on tapping tools may be defined using the scratch test.

Conclusion

The Bruker UMT TriboLab tapping torque test rig evaluates tool materials, metalworking fluids, and workpiece material combinations flexibly and practically. Cutting and forming tap performance efficiency can be evaluated using various sizes of tapping tools, varying from M2 to M10, and their pre-drilled counterparts.

UMT TriboLab delivers unmatched adaptability and efficiency for many types of ASTM, DIN, SAE, and other customized testing by augmenting the tapping torque test rig with additional sensors, automated test processes, and data display.

References

- ASTM D5619-00 (2011), Standard Test Method for Comparing Metal Removal Fluids Using the Tapping Torque Test Machine (Withdrawn 2016), ASTM International, West Conshohocken, PA, 2011.

- ASTM D8288-19, Standard Test Method for Comparison of Metalworking Fluids Using a Tapping Torque Test Machine, ASTM International, West Conshohocken, PA, 2019.

- G. Ramirez and I. Miller, “Simulating the Friction of Lubricants and Materials with a High-Frequency Reciprocating Rig,” Bruker Application Note 1016 (2019).

- S. Shaffer and S. Lesko, “Evaluating Cutting Tool Coatings with Scratch Testing,” Bruker Application Brief 1014 (2019).

This information has been sourced, reviewed and adapted from materials provided by Bruker Nano Surfaces.

For more information on this source, please visit Bruker Nano Surfaces.