Superior performance for the measurement of Ultra-low sulfur diesel (ULSD) for control and certification of 10 – 15 ppm S at the pump, as well as lower levels for product release at the refinery.

Regulations around the world have limited the amount of sulfur in various fuels and oils. In some regions, sulfur in diesel is limited to 10 – 15 ppm, while other areas of the world are working to bring sulfur levels down to 50 ppm and lower.

Aside from automobiles, trucks, and some bunker fuels, ULSD is also used as a starter fuel in coal-fired power plants in some regions and as a backup fuel for electricity generation in nuclear power plants. Thus, a fast, reliable method of measuring and monitoring sulfur concentration throughout the petroleum industry is vital.

The NEX CG II gives the industry a reliable tool for measuring ULSD using full polarization in 90° Cartesian Geometry EDXRF. Polarization creates an extremely low background in the measurement, allowing for very low detection limits for reliable measurement in the ultra-low range to meet international testing norms and EPA testing criteria demands.

Image Credit: Rigaku Corporation

Instrumentation

Model: Rigaku NEX CG II

X-Ray tube: 50 W Pd-anode

Excitation: Indirect with polarization

Detector: Large-area SDD

Analysis time: 300 seconds

Environment: Helium purge

Film: Polypropylene 4 μm

ASTM, EPA and International Norms

The Rigaku NEX CG II EDXRF analyzer meets several international norms and EPA testing criteria for the measurement of sulfur in petroleum oils, fuels, and ULSD using monochromatic EDXRF.

Table 1. Source: Rigaku Corporation

The units ppm and mg/kg can be used interchangeably

Sample Preparation

Ensure each sample is homogeneous and stable. Shake the sample gently and allow bubbles to settle. Fill a 32 mm XRF sample cup with 4.0 g of sample to ensure consistent sample depth. Polypropylene film (4 μm) is used to ensure optimal X-Ray transmission. Make the measurement immediately after filling the cup.

Calibration

Empirical calibration was built using a suite of six commercially available certified diesel calibration standards.

Table 2. Source: Rigaku Corporation

Image Credit: Rigaku Corporation

Precision

Instrument repeatability (precision) is determined by ten repeat analyses of each sample in a static position using a 300-second analysis time per measurement.

Table 3. Source: Rigaku Corporation

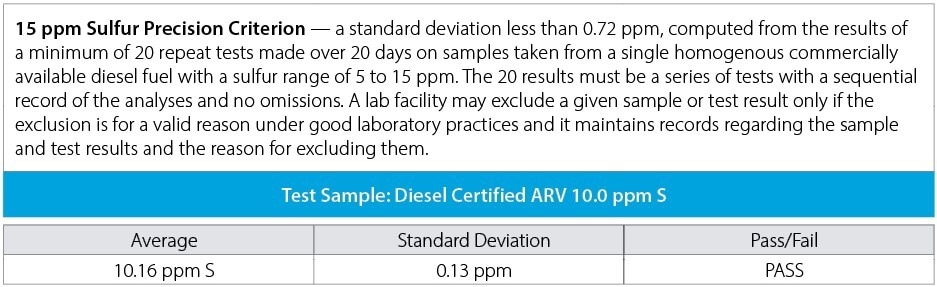

U.S. EPA Testing Criteria 40 CFR 80.584

The following results indicate that the NEX CG II can be used by a facility to meet EPA ULSD criteria as per 40 CFR 80.584 using ASTM Standard Test Method D7220 and good lab practices.

Table 4. Source: Rigaku Corporation

Detection Limits

The empirical method was used to determine the detection limit. In the empirical method, ten repeat analyses of a blank diesel sample containing no sulfur are taken with the sample in a static position, and the standard deviation is determined. The lower limit of detection (LLD) is then defined as three times the standard deviation.

Table 5. Source: Rigaku Corporation

LLDs shown are typical and may differ depending on measurement time used and the overall elemental composition of the sample being tested.

Conclusion

The results presented in this article indicate that the Rigaku NEX CG II EDXRF analyzer using Cartesian Geometry polarization provides monochromatic excitation to achieve superior performance for the measurement of ULSD for control and certification of 10 – 15 ppm S at the pump, as well as lower levels controlled at the refinery.

The versatility of the NEX CG II makes it an ideal tool for measuring many other elements, oils, and fuels as well. It is well suited for measuring ultra-low chlorides by ASTM D4929, ultra-low metals by ASTM D8252, lube oils, wear metals in oils, and used oil and waste oils to meet the demands for ultra-low measurements throughout the petroleum and recycling industries.

This information has been sourced, reviewed and adapted from materials provided by Rigaku Corporation.

For more information on this source, please visit Rigaku Corporation.