Mobile phones have revolutionized our lives in ways nobody could have predicted 30 years ago. In the last few years, mobile phones have transformed from simple communication devices to portable computers through the innovative use of different materials and elements.

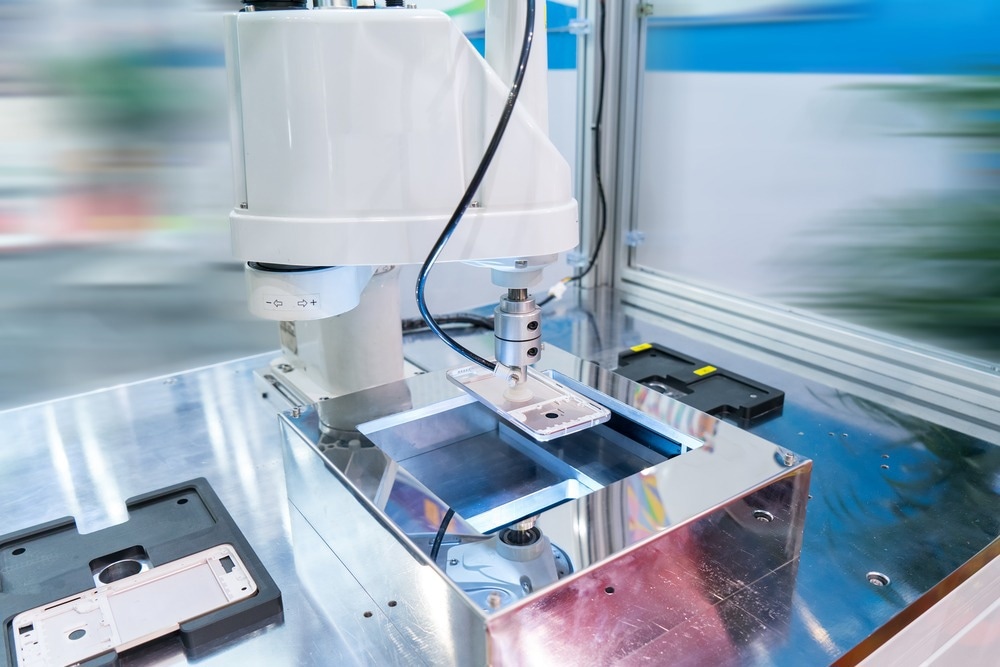

Image Credit: asharkyu/Shutterstock.com

What’s Inside a Mobile Phone?

The rise of mobile phones over the last decade is the most significant technological shift since the internet’s establishment as a global communication network in the 1990s. Since then, our lives have changed rapidly.

The seemingly limitless capabilities of mobile phones as entertainment gadgets, communication devices, and personal organizers are made possible by the unique qualities of the materials present within a mobile phone.

Various metals, composites, and compounds extracted from minerals and ores make up the electronic components of mobile phones. The perfect harmony of electronics and chemistry makes it possible for mobile phone users to communicate with the rest of the world via voice calls, text messages, and social media platforms.

As mobile phone technology advances, the chemical elements used to construct these devices will continue playing a crucial role in expanding their remarkable capabilities.

Plastic

Plastic is not naturally occurring in the environment. Instead, it is the byproduct of processing crude oil.

Plastic is mainly used to manufacture computer chip coatings, protective casings, and electrical components. Most mobile phone plastics are thermoset plastics such as fluoropolymer, polymethylmethacrylate, polypropylene, polycarbonate, phenol formaldehyde, and styrene because they are resistant to wear and the heat generated due to constant use.

Glass

Glass is a significant component of a mobile phone, particularly the screen; however, this is no ordinary glass. This glass is composed of silicon dioxide and aluminum oxide, with an ultrathin coating of indium tin oxide added so that the screen can be used without damage.

Most mobile phone manufacturers now employ Gorilla Glass, a lightweight, thin, fortified glass produced by Corning.

Metals

Metals are used in the circuitry and batteries of mobile phones. However, metals are not in their purest form when extracted from the ground. They are initially extracted from their minerals or ores before being used in mobile phones.

The following are some of the metals used in mobile phones:

Lithium

Lithium is a lightweight rare earth metal with a high electrical storage capacity. As a result, it is principally employed in producing mobile phone batteries. It is mined from hard-rock ores and salt lakes.

Silicon

Silicon represents almost 25% of the materials used to manufacture a smartphone. It is mainly used to make the processor of the mobile phone. Silicon is one of the most widely used materials in manufacturing mobile phones due to its unique properties as a semiconductor.

It is also very cheap since it is found in almost 30% of the Earth’s crust.

Iron

Iron is mainly used for all the screws necessary to assemble the different components of mobile phones. Iron alloys are also used to make body parts and batteries. It makes them highly durable and resistant to oxidation.

Aluminum

The most common use of Aluminum is to house electronic components of a mobile phone. On average, 22.18 grams of Aluminum is used in a smartphone. It serves as a shielding layer to protect the circuitry from the antenna’s electromagnetic radiation.

Copper

Copper is used more than any other metal in mobile phone components due to its high electrical and thermal conductivity. The main destination of this material is the cable of the devices.

In addition, chips and printed circuits contain copper because of its excellent electrical conductivity, while heat sinks are made from copper due to its very high heat dissipation factor.

Cobalt

Cobalt is the most expensive raw material used to manufacture lithium-ion batteries. It is used with Lithium to extend the life of mobile phone batteries as it provides the highest energy density among metals.

In addition, coating copper wires with cobalt improves their durability.

Tin and Lead

Tin is valued for its unique physical properties, availability, and low cost, and it is used mainly to connect different components to the motherboard via solder joints.

In addition to tin, lead is also used to make some of the solders thanks to its ductility.

Zinc

Zinc alloys with Aluminum and copper are used to manufacture microphones and speakers. It is also used in the manufacturing of batteries.

Nickel

Nickel is a tough, malleable, silvery metal used in mobile phone batteries, capacitors, and electrical connectors.

Silver

Due to its high electrical conductivity, silver is used to make conductors, switches, contacts, and conductive lines of the printed circuit.

Gold

Gold is highly electrically conductive and corrosion-resistant. It produces conductors, switches and buttons, RAM, motherboards, and cables.

Health Risks and Environmental Hazards Associated with the Raw Materials of Mobile Phones

A single mobile phone contains various materials that the EU Commission classified as rare Earth metals in 2014. In some countries, these materials are obtained through mining, which is difficult and life-threatening.

Aluminum, copper, and its supply chain are related to high CO2 emissions and soil and water contamination risks.

Image Credit: asharkyu/Shutterstock.com

Due to their increasing popularity and limited lifespan, mobile phones constitute an ever-growing waste stream. Often, these gadgets cannot be repaired after malfunctioning. Moreover, less than 20% of smartphone components are recyclable. As a result, a growing amount of electronic waste or e-waste accumulates on Earth.

The amount of e-waste on Earth in 2018 was around 50 tons and is constantly increasing. In addition, the dangerous metals in old mobile phones can pollute our water supply if they are not properly recycled or disposed of.

Each mobile phone manufacturer has to look beyond its first consumer and consider creating a circular economy that reduces or eliminates waste by recycling valuable materials back into the manufacturing process.

These strategies could be advantageous for customers and the environment. However, devices hibernating in homes significantly hamper the adoption of circular economy strategies in the mobile phone value chain.

References and Further Reading

Jenness, J. E., Ober, J. A., Wilkins, A. M., & Gambogi, J. (2016). A world of minerals in your mobile device (No. 167). US Geological Survey. http://dx.doi.org/10.3133/gip167

Lotzof, K. (2020). Your Mobile Phone is powered by Precious Metals and Minerals. [Online]. Natural History Museum. Available at: https://www.nhm.ac.uk/discover/your-mobile-phone-is-powered-by-precious-metals-and-minerals.html

Trento, C. (2022). What is the Material of Your Phone Body? [Online]. Stanford Advanced Materials. Available at: https://www.samaterials.com/content/what-is-the-material-of-your-phone-body.html

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.