Natural gas-fired turbine engines are known to produce formaldehyde – a substance that has been recognized as a carcinogen by both the US Department of Health and Human Services and the International Agency for Research on Cancer. It is for this reason that regulations require gas-fired turbine engines to be monitored periodically by emission testing firms.

The US Environmental Protection Agency (EPA) Stationary Combustion Turbine Regulation (40 CFR Part 63 Subpart YYYY) demands that this type of turbine limit formaldehyde emissions to a maximum of 91 parts per billion (ppb) by volume, dry basis (ppbvd) at 15% O2. Gas turbine manufacturers make great efforts to design their combustion “hot section” such that formaldehyde emissions are minimized, and the concentration levels of formaldehyde continuously emitted from these sources are generally low (around 0.1 ppmv). The volume of exhaust gas from gas turbines is quite large, and the pollutant's total mass may still be significant enough to pose a hazard to human health.

Measurement Challenge

Source testing professionals need an analytical technique that can measure less than 91 ppbv formaldehyde with precision in real-time from a natural gas-fired turbine. FTIR gas analyzers in some configurations, following EPA Method 320, are able to reach this low level.

Still, it is often the case that the analyzers do not offer the precision needed to measure formaldehyde emission accurately. EPA Method 0011 is also employed, requiring the use of collection impingers and a derivatizing reagent [2,4-dinitrophenylhydrazine (DNPH)]. This is then followed by high-pressure liquid chromatography (HPLC) with UV-Vis detection which lacks precision and is also not a real-time measurement. For efficiency, a real-time analysis methodology with single-digit parts per billion (ppb) detection limits.

Solution

The Thermo Scientific™ MAX-iR™ FTIR Gas Analyzer with Thermo Scientific™ StarBoost™ Technology (an optical enhancement) can meet this challenge. The FTIR analyzer with optical enhancement is referred to as OE-FTIR. The StarBoost optical technology increases the detector linearity, sensitivity and dynamic range of the FTIR gas analyzer in a significant way. This breakthrough technology enables real-time, single-digit ppbv detection of hazardous air pollutants (HAPs) like formaldehyde.

The OE-FTIR system (MAX-iR analyzer with StarBoost technology) utilizes a longpass optical filter which facilitates the measurement of compounds in the range of 1,900 – 3,300 cm-1. This filter system can measure hydrocarbons and other oxygenates simultaneously, including CO, CO2, CH4, and H2O.

As well as the MAX-iR analyzer with StarBoost technology, there is a novel technique for zeroing the analyzer using stack emissions. The Thermo Scientific™ MAX-OXT Thermal Oxidizer Module selectively removes the target analyte from the sample matrix without reducing the concentration of atmospheric interferences such as CO2, H2O and CH4. As a result, an interference spectrum can be collected and added to the regression in real time to give improved IR residual and formaldehyde data quality. If the interference spectrum is not used in the regression, the MAX-OXT module is still a powerful data validation tool.

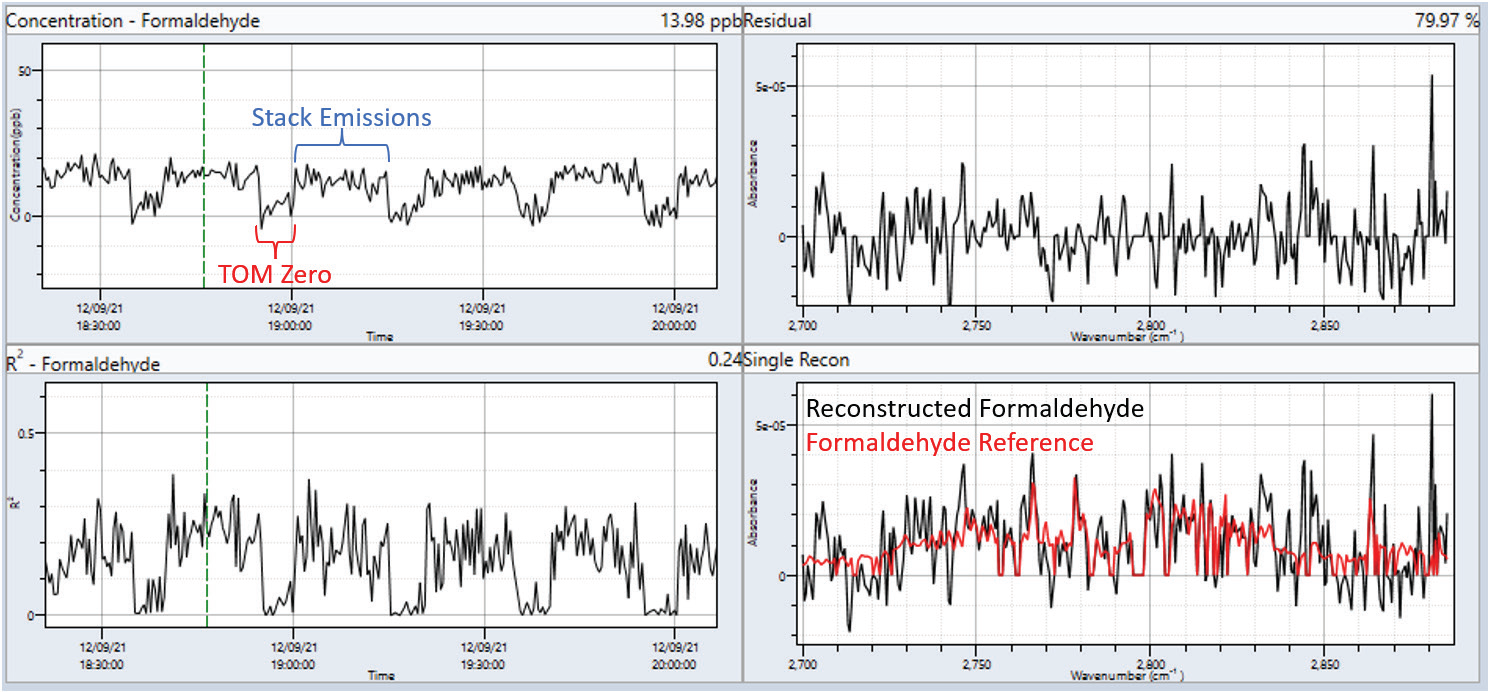

Figure 1. Formaldehyde measurements collected in the field from a natural-gas fired turbine engine. Image Credit: Thermo Fisher Scientific – Materials & Structural Analysis

Experimental

Data was collected from a natural gas-fired turbine to demonstrate the ability of the OE-FTIR platform to measure formaldehyde emissions. Data were zeroed periodically using the MAX-OXT module. When switching between MAX-OXT oxidation and sample gas, the response time is less than 15 seconds at 5LPM sample flow, allowing formaldehyde to be rapidly detected. Results from the test are given in Figure 1.

The top left panel gives a plot of the formaldehyde concentration (in ppb) during the data collection period.

The formaldehyde concentration was 13.98 ppb for the selected sample spectrum, indicated by the green dashed line. This application used a MAX-OXT module for the periodic removal of the formaldehyde from the sample and collection of interference spectra, as shown in the concentration plot.

The formaldehyde concentration can be validated easily down to 10 ppb when these spectra are added to the regression matrix. This technique reduces bias in the formaldehyde measurement to a minimum due to spectral interference, which is key for the accurate measurement of compounds on a 10-ppb scale.

A standard deviation of 1.37 ppb on the formaldehyde measurement indicates that the minimum detection limit for this test was 4.11 ppb. The formaldehyde is visible in the regression reconstruction at a concentration of 13.98 ppb.

Conclusion

This application article demonstrates that the MAX-IR analyzer with optional StarBoost technology (OE-FTIR) can measure low ppb levels of formaldehyde from natural gas-fired turbine engines. The ease of sampling and data flow allow for more efficient measurement compared to EPA Method 0011.

Previously it might have taken hours for a result; the analysis can now be carried out in minutes, saving the source tester aggravation, time, and money. Furthermore, the increased precision of the enhanced analyzer ensures that the result will truly reflect the actual formaldehyde levels sampled during the test.

This information has been sourced, reviewed and adapted from materials provided by Thermo Fisher Scientific – Materials & Structural Analysis.

For more information on this source, please visit Thermo Fisher Scientific – Materials & Structural Analysis.