In recent decades, the preparation of samples for transmission electron microscopes has transformed, thanks to the introduction of focused ion beam (FIB) instruments. Known as either single-beam or dual-beam focused ion beam microscopes, these instruments have revolutionized sample preparation for transmission electron microscopy, improving processes, performance, and efficiency.

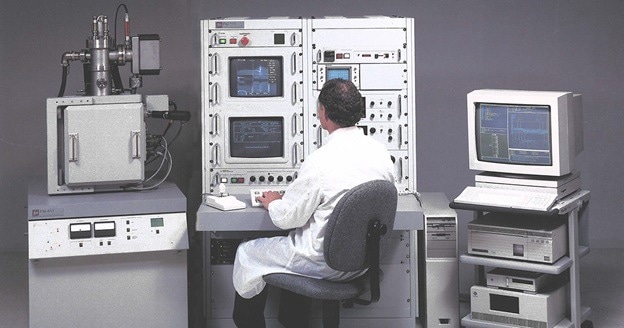

This photo, taken in 1989, shows an original TEM workstation. Thermo Fisher Scientific developed the first single-beam Ga+ FIB, allowing sub-microscale site-specific material removal, enabling technology for site specific sample preparation. Image Credit: Thermo Fisher Scientific – Electron Microscopy Solutions

This article describes the contribution of FIB instrumentation to materials science, examining its history, implementation, the advantages of the technology, and its influence on modern life.

History of Focused Ion Beam (FIB) Instruments

FIB has dramatically simplified measuring a ‘biopsy’ of a sample. Before FIB, it was difficult to standardize sample preparation and imaging, so different samples from the same material would show different results.

The sample quality depended on the individual operator, who required extensive practice before becoming an expert. Sample analyses also required multiple tools and instruments, making obtaining consistent results difficult. As a result, sample prep typically required several days to prepare just one sample, keeping scientists from performing their actual research analysis.

The introduction of single-beam FIB instruments in the mid-1990s represented change. A single-beam FIB 200 arrived at Cambridge University in 1995, and the heavy reliance on manual sample preparation for transmission electron microscopy ended.

Techniques were rapidly discovered and advanced to preserve fragile layers of oxidized materials, which had historically posed problems for scientists.

The accelerating voltage could be manipulated to improve surface finishes, and damage could be assessed using groundbreaking new techniques. After its introduction, it became rapidly clear that the potential implications of this new technology were significant.

Some examples of developments brought about by single-beam instrument technologies include improved indentation techniques, enabling localizations of thin sections underneath indentation tips to observe how the material reacted under pressure. Such developments completely changed semiconductor design.

Advantages of FIB Instruments

FIB instruments enabled the localization of an area or defect and the subsequent creation of a cross-section to be thinned and examined on a transmission electron microscope. This was a significant change from the indiscriminate thinning of the past, which had a much lower success rate. This new precision was essential to solve some of the critical questions posed to materials scientists.

In the early 1990s, FIB instrumentation started to become widely adopted, particularly by semiconductor laboratories that needed a tool to identify defects.

The DualBeam instruments, developed by FEI (now part of Thermo Fischer Scientific), allowed for easier preparation of thin sample layers and exact study of particular sample regions with high-resolution TEM. This made it possible to isolate and analyze specific spots on a sample, like one faulty transistor among several million on a semiconductor chip.

The dual-beam instrument provided accuracy and repeatability. This consistency allowed laboratories to understand the time requirements of their analysis better and predict when samples would be ready for TEM analysis.

The quality of TEM samples and sample throughput have improved, and features such as in-situ lift-out and advanced polishing methods were added. All of this made FIB a powerful instrument for analyzing material microstructures.

Some examples of the innovation include the development of the Sidewinder and Tomahawk FIB columns in the 2000s which improved polishing capabilities at low voltages. In the 2010s, the introduction of the first plasma FIB by FEI meant far higher material removal rates and less sample contamination than previous FIBs using gallium ion sources.

Implications and Effect of the Dual-Beam FIB

The dual-beam FIB was so revolutionary that it transformed TEM sample preparation and other areas. The preparation of atom probe samples proved complex and challenging with the single-beam FIB, but the high-quality electron beam of the dual-beam provided additional clarity needed for such precise work. Today, almost 100% of the dual-beams are used for sample preparation for transmission electron microscopy within the industry.

Such instruments make modern life possible in everything from toasters and microwaves to smartphones.

The Future of Dual-Beam FIB Technology

Ion beam analysis continues to create ripples through the wider community. This revolution of localized sample preparation has increased the pace of research across the board. One of the most evident impacts can be seen in aerospace engineering, with the improvement of alloys in engine turbine blades and magnetic devices for head manufacturers.

In the future, experts believe that dual-beam instrumentation will continue to play a part in sample preparation for fundamental materials research with TEMs. A global shift driven by innovation and environmental conservation displays an increasing trend towards ‘softer’ materials - a hybrid between organic and inorganic - to reduce pollution and fuel usage and for the development of batteries, solar cells, etc.

Additional modalities may be added to ion beam instruments to analyze and obtain data from such materials, which will become ever more useful in the push toward innovation.

At present, the Helios 5 DualBeam is the standard for TEM and STEM sample preparation with the ability to standardize sample preparation, improving consistency and also avoiding issues with gallium contamination. A key part in achieving this is the use of the AutoTEM 5 Software for automated control of processes such as lamella preparation and sample polishing.

Higher degrees of instrument automation mean that TEM sample preparation is now accessible to researchers of all skill levels. Sample preparation times can now be as low as 45 minutes, accelerating research in fields such as batteries, polymers, metals, and more.

David Foord, Product Director for TEM at Thermo Scientific, summarizes what he views as the driving force behind ion beam technology. Rather than advancement for its own sake, he believes the central question should be: “What problem is this technology going to solve in the end?”

By making that the heart of its scientific work, Thermo Scientific may drive the field of materials science forward and usher in a new age of solutions-focused innovation.

To listen to the full history of TEM sample Preparation, please listen to the podcast with David Foord here.

This information has been sourced, reviewed and adapted from materials provided by Thermo Fisher Scientific – Materials & Structural Analysis.

For more information on this source, please visit Thermo Fisher Scientific – Materials & Structural Analysis.