In this interview, Chris Nicholas discusses catalyst technology that has allowed for more sustainable production of acrylic acid and acrylates. This research has inspired the startup Låkril Technologies Corporation, which is looking to commercialize this technology.

Please can you introduce yourself and your professional background?

My name is Chris Nicholas; I’m the Co-Founder and President of Låkril Technologies Corporation, a young company that envisions a world where bio-based sugars are used as the feedstock to produce low-carbon chemicals. Previously, I worked in the Honeywell UOP organization where I spent 15 years inventing and commercializing catalysts for refining processes after earning a Ph.D. from Northwestern University in catalytic chemistry.

In new research, you have demonstrated a catalytic technology to convert chemicals from corn into acrylic acid and acrylates. Why is a more sustainable production method for these chemicals necessary?

Today’s production of over 6.5 million metric tons of acrylic acid supports a $10B+ industry across the paints, coatings, adhesives, and superabsorbent polymers markets. The problem is that over 16 million metric tons of CO2 are emitted yearly to produce this acrylic acid. Our process for the dehydration of lactic acid to acrylic acid will lead to at least 35% CO2 reduction versus today’s methods and could potentially accomplish carbon sequestration.

Industry has sought this bio-based, low carbon route to acrylics for over a decade; the problem has always been economics. Our acrylic yields of greater than 90% from lactic feedstocks provide an opportunity not previously seen.

Could you describe the catalyst formulation used in your research?

As recently shown in our paper in JACS Au, our catalyst innovation incorporates a bifunctional catalyst comprising a solid acid and proprietary amines. This patent pending concept utilizes the amine to control the dehydration of alpha-hydroxy acids such as lactic acid and/or lactates. We, therefore, avoid significant side reactions including decarboxylation which generate undesired byproducts.

How is your method better than previous attempts to convert lactic acid into acrylates?

We have benchmarked our catalyst against other attempts, both in the patent and open scientific literature. Our catalyst innovation achieves greater than 90% yields, the first time a catalyst has delivered yields at or above what has long been expected to be the commercialization hurdle for this reaction. Most other catalysts used previously achieve 75% or lower yields of acrylic products from lactic feedstocks.

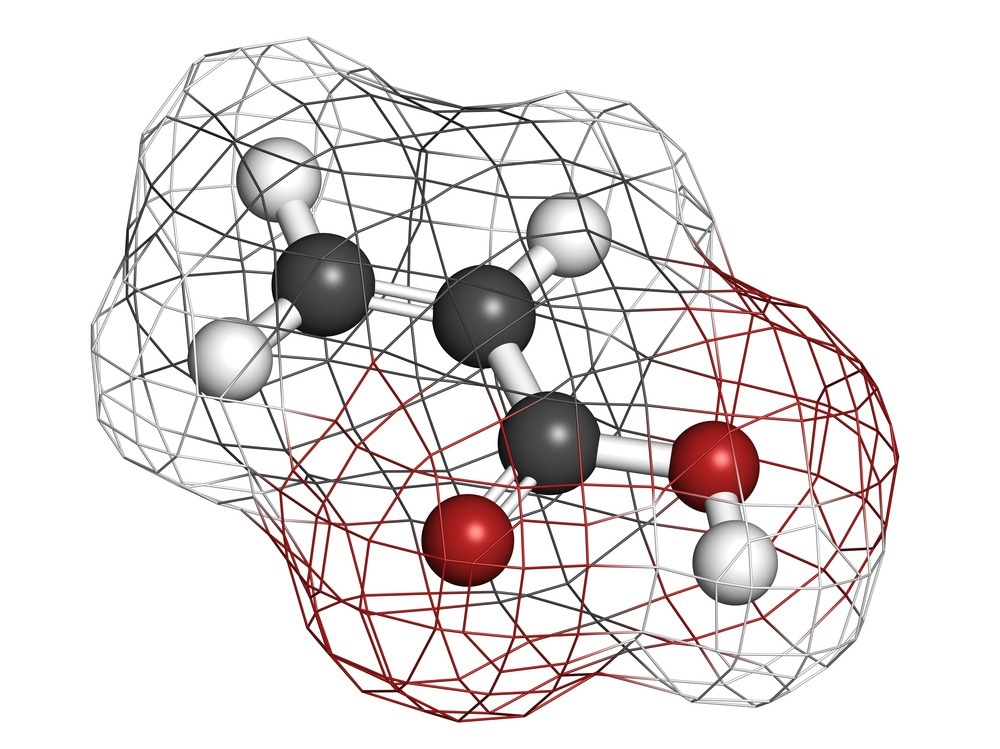

Image Credit: StudioMolekuul/Shutterstock.com

As CEO of Låkril Technologies, a startup company born from this technology, could you describe the commercial value of your catalytic formulations?

Today’s consumers are increasingly looking for bio-based, low-carbon alternatives for a more sustainable lifestyle. The National Academies recently identified a near-term need for low-carbon chemicals in order to start reducing CO2 intensity at the lowest possible cost of implementation. The acrylic acid and/or acrylates produced from our conversion method allow the fulfillment of these needs and desires without the significant cost in time and development of reformulating the multiple paints, coatings, adhesives, and superabsorbent polymers in use today.

How does the cost of production using your method compare to fossil-derived chemical production?

Our lactic-to-acrylic process is within striking distance of today’s acrylic acid production cost and has the potential to deliver costs below that seen today. As per usual in the bio-derived chemicals world, the single largest contribution to cash cost of production is the lactic acid feedstock.

What are your immediate next steps?

Låkril Technologies is involved in a 3yr runway of scaling and gated technical improvement with approaches to market in 2024-2025. We are at present engaged in a series of development thrusts ranging from process improvement and scaling to additional catalyst improvements.

Where can readers find more information?

https://lakril.com/index.html

https://linkedin.com/company/lakril-technologies

https://twitter.com/LakrilTech

About Chris Nicholas

Chris is the Co-Founder and President of Låkril Technologies, the startup he created in 2021 to commercialize a catalytic process for bio-based acrylic production. Prior to founding a business based on sustainable catalysis, he worked 15 years at Honeywell UOP in technical and managerial roles primarily focused on inventing and catalytically testing new materials and processes. Particular foci have included heterogeneous catalytic processes such as olefin oligomerization and alkylation, synthesis of inorganic materials (primarily metal oxides and zeolites), process engineering, molecular adsorption, and olefin metathesis. Chris earned his Bachelor of Arts from Kalamazoo College and a PhD at Northwestern University. Chris is a 25-year ACS Member and an AIChE Senior member who is an inventor on more than 115 issued US and foreign patents and the coauthor of 30+ peer-reviewed journal articles and a book chapter. He has received the 2020 Herman Pines Award in Catalysis from the Chicago Catalysis Club and the 2022 Award for Excellence in Catalysis from the Southwest Catalysis Society.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.