In this interview, AZoM speaks with Dr. Yufeng Zheng, Assistant Professor and Director of the Electron Microscopy Core Shared Facility at the University of Nevada, Reno (UNR), about the capabilities and research conducted at the facility in recent years. He also discusses the future of microscopy at UNR and workshops on the horizon.

What kind of research and capabilities does the Electron Microscopy and Microanalysis Facility at the University of Nevada, Reno offer to the scientific community?

The Electron Microscopy and Microanalysis Facility at the University of Nevada, Reno, provides cutting-edge instrumentation and extensive experience to the research community. The facility serves materials science, surface analysis, engineering, Li battery development and many other fields.

The facility is directed by practiced professionals, utilizing modern instrumentation to bring the nano-world to life and pave the way for the future of science and technology. It is part of the continually growing Department of Chemical and Materials Engineering at the university, which was built on the mantra that “access to education and knowledge is essential to human progress.”

This facility is one of many areas of study at the University of Nevada, Reno, which has been serving students and advancing the scientific community for almost 150 years.

Image Credit: University of Nevada, Reno

What are some of the cutting-edge research instruments available at the Electron Microscopy and Microanalysis Facility at the University of Nevada, Reno?

Over the last few years, the department of engineering along with the medical school have combined forces and sought state as well as NSF funding to give the facility a technology refresh. A recent edition of a Thermo Scientific Talos F200S Scanning / Transmission Electron Microscope (S/TEM) replaced two outdated systems and empowered researchers in the region by providing access to capabilities that target modern nano-scale analysis that can address a wide variety of samples.

Also at the disposal of users are a variety of TEM holders, a nanoindenter, an in-situ micro-mechanical testing system, a Thermo Scientific Scios 2 Focused Ion Beam Scanning Electron Microscope (FIB-SEM) and a Nova600 NanoSEM.

Figure 1. Picture showing Mr. Dian Li, a Ph.D. student of Dr. Yufeng Zheng at UNR, working on Talos F200S S/TEM.

Image Credit: University of Nevada, Reno

What feedback have you had on the Talos F200S Scanning/Transmission Electron Microscope, and what are the plans to train more users of the equipment?

The facility and Dr. Zheng continue to actively collaborate with life science as well as other groups to introduce the technology and capabilities of the facility to a wider range of researchers. In order to design and advance research projects, potential users “need to know what they can do and what data they can obtain”, said Dr. Zheng.

In a recent workshop conducted on campus to introduce the technology and capabilities to groups outside of materials science, there was a great amount of positive feedback. “People like what they see,” said Dr. Zheng, and moreover the Talos “has been working perfectly for the past 18 months” (since it was installed). “It is a very versatile tool that can benefit research from materials science and life science … we have many potential users so we want to train more new users”, he mentioned.

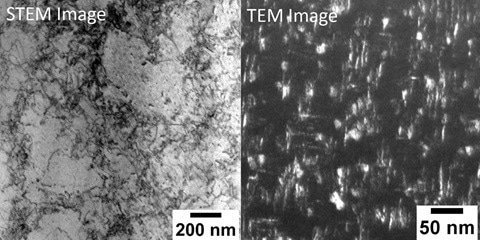

Figure 2. STEM and TEM images recorded from FEI Talos F200S S/TEM. STEM image showing dislocations in the additively manufactured stainless steel and TEM image showing nanostructures in the high-strength, lightweight titanium alloy.

Image Credit: University of Nevada, Reno

What are the benefits of the similar, intuitive user interfaces amongst the various Thermo Fisher instruments at UNR?

The availability of intuitive and analogous interfaces between various Thermo Fisher instruments at UNR makes it easier for users to quickly understand the equipment and move between different platforms in order to collect the data they need.

[I am] very impressed with the stability of the Talos. It saves users and students a lof of time.

Dr. Yufeng Zheng, Assistant Professor and Director of the Electron Microscopy Core Shared Facility

The system incorporates new technologies and constant power lenses, eliminating the need for day-to-day alignments that many have traditionally been required. The remote capability has been a game changer for the university.

It allows operators to use a remote set of control panels and link from just about anywhere, including the classroom. Dr. Zheng said the remote capability was “especially important for me as I use that function in my class …. to a big group of students.” The remote operation can also easily be broadcast within the campus, so medical center users can easily run the microscope from their building, leading to more research being carried out with increased efficiency. It is a win-win for all.

What are the goals for the facility and how is UNR planning to achieve them?

The facility is already equipped with great FIB preparation equipment as well as unique tensile, cryo, 3D characterization and other in-situ capabilities for TEM so one next step is to ramp up utilization of these approaches for internal and external academic researchers as well as the local industry.

Dr. Zheng's goal is to provide comprehensive imaging and support for interdiciplinary analyses so that users truly understand the data they collect, not just observing nice images.

Come one, come all and bring your samples! Future workshops for life science, materials science, and battery are also in the works so be on the lookout!

Figure 2. Dr. Yufeng Zheng winning the prestigious National Science Foundation CAREER Award to study novel nanostructures in titanium alloys using FEI Talos F200S S/TEM.

Image Credit: University of Nevada, Reno

About Dr. Yufeng Zheng

Dr. Zheng joined the University of Nevada, Reno, in 2019 as an Assistant Professor in the Department of Chemical and Materials Engineering. Prior to his current role, he was a research associate at the Center for the Accelerated Maturation of Materials at Ohio State University from 2014-2019. His scientific focus includes novel metallic materials design (titanium alloys, high entropy alloys, and superalloys), additive manufacturing (LENS), advanced characterization (electron microscopy and atom probe tomography), phase transformation, and deformation mechanisms in metals.

Dr. Zheng received his Ph.D. in Materials Science and Engineering from Ohio State University, Columbus, OH, in 2013. He also received numerous awards, including the Early Career Development Program (CAREER) from the National Science Foundation in 2022 and the Acta Journals’ Outstanding Reviewer in 2020 as well as Scripta Materialia in 2021.

This information has been sourced, reviewed and adapted from materials provided by Thermo Fisher Scientific – Materials & Structural Analysis.

For more information on this source, please visit Thermo Fisher Scientific – Materials & Structural Analysis.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.