Electron microscopes have become a common sight in many university departments thanks to their high versatility and utility in bringing the nano-world to life. With spatial resolution and analytical capabilities far beyond what a typical light microscope can achieve, electron microscopy has become a tool of choice for imaging nanoscale structures in both materials and biological applications.

At the University of Kentucky, the Electron Microscopy Center (EMC) serves over 30 different research groups from more than 15 departments and has over a hundred regular users. These users come from a variety of scientific disciplines and backgrounds, but all share the commonality of a desire to investigate the cutting-edge science of today’s nano-world at a scale too small to be easily seen.

What kind of scientific insights does the Electron Microscopy Center (EMC) at the University of Kentucky provide?

The EMC is a multi-user shared facility that offers comprehensive imaging and multimodal analysis using various techniques and instrumentation platforms.

This includes key scientific insights for users from academia and industry through a personalized approach carried out by experienced staff. The center helps researchers from various fields find answers to difficult questions by providing support from initial planning and preparation of research goals to final images and data analysis.

What are some of the research fields that use the EMC, and what kind of instrumentation and capabilities does the center provide for users?

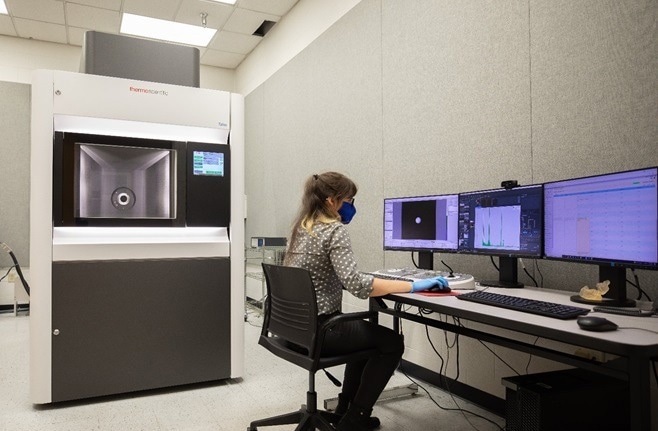

The EMC at the University of Kentucky has been modernized over the last ten years to support advancements in first-class research. The center is a part of the National Science Foundation's NNCI initiatives and serves users from fields such as materials science, chemistry, physics, and biomedical engineering. The center houses a Thermo Scientific Helios NanoLab 660 FIB-SEM and a Thermo Scientific Talos F200X (S)TEM, which allow for imaging and analytics down to the atomic level.

The Helios Nanolab 660 was the first available for general research use in Kentucky. It opened new opportunities for 3D characterization and transmission electron microscopy (TEM) sample preparation, revolutionizing the user base and creating opportunities to address challenging scientific questions.

EMC user at the controls of the Helios NanoLab 660 FIB-SEM. Image Credit: University of Kentucky

What was the need for a new TEM at the EMC, and what steps were taken to fulfill this need?

To meet the growing need for high-resolution TEM studies, an effort was made to acquire a new TEM system. The Associate Dean for Research and Graduate Studies explored funding options through NSF MRI and DoD equipment funding applications, but ultimately, no awards were received. However, by partnering with internal stakeholders at the university who shared the same vision of transforming and revitalizing the EMC facility, they were able to successfully procure a Talos F200X (S)TEM.

“We realized we can no longer do state of the art research and be competitive with outdated 20-year-old equipment. Our students and researchers wanted to replicate what they saw in current publications, and we just couldn’t do that with the equipment we had.,” said Professor Balk.

The Talos F200X features strong TEM/STEM imaging capabilities and advanced analytical capabilities such as a 4-detector Super-X EDS system, an EELS package, the latest cameras and STEM detectors, and various in situ holders.

We are not the type of facility that has the need for an aberration corrected TEM, but we benefit enormously from a state-of-the-art non-corrected FEG (S)TEM with full analytical capabilities, like Talos. We cover a lot of research ground with our instrumentation and characterization capabilities.

Professor John Balk, Associate Dean for Research and Graduate Studies.

To fully utilize the capabilities of the new TEM, Automated Particle Workflow (APW) and Small-Angle X-ray Scattering (SAXS) were implemented for the cohesive analysis of nanoparticles and precipitates in steel as well as high-entropy alloys. This led to new approaches in characterizing large numbers of nanostructures and possible future collaborations in the field.

EMC staff scientist Jillian Cramer at the controls of the Talos F200X (S)TEM. Image Credit: John Balk, University of Kentucky

What is the approach of the EMC in terms of educating its users, and how does it differ from other facilities?

The EMC deeply commits to educating users in electron microscopy, analysis, sample preparation, and associated techniques. In addition to individualized training sessions, the staff offers a combination of theoretical and hands-on classes to educate potential users about the most practical instrument for their application.

Professor Balk commented that when he started as the EMC director about 12 years ago, he “really wanted to change things significantly” and put a lot of emphasis on guiding people to the right instrument to maximize their research impact. “We create a supportive and non-intimidating environment and are not just a factory that puts out samples and data.”

This real-world in real-time approach to analytical techniques sets the facility apart and brings users in from all over the region. The training sessions often involve a researcher’s actual samples, not just standard samples, whcih often reduces the time from conception to meaningful results.

EMC staff scientists have broad expertise in instrumentation and applications, training new users and helping them get the best possible data from their samples. They frequently work with Thermo Fisher Scientific applications scientists to stay up to date on the fast-evolving technology and update software several times a year to add new capabilities to their equipment.

What does the future hold for materials characterization at the University of Kentucky?

The University of Kentucky has recently acquired two new instruments, a Thermo Fisher Axia ChemiSEM scanning electron microscope and a Thermo Fisher HeliScan MicroCT instrument, which will be used for a wide range of investigations, such as heritage studies and 3D analysis of additive manufacturing as well as bio-medical applications.

These instruments are expected to change the game for many projects. Furthermore, the EMC recently hosted a summer workshop that brought together researchers to discuss electron microscopy applications in biomedical research, and similar events are planned for the future.

About John Balk

Professor John Balk has taught materials engineering at the University of Kentucky for 14 years. In 10 of those years, he received the Materials Engineering program’s outstanding teacher award. In 2009, he collected not only the program’s award, but also the College of Engineering’s Henry Mason Lutes Award for Excellence in Teaching and the university-wide Provost’s Award for Outstanding Teaching. He has held the position of Associate Dean for Research and Graduate Studies since 2018. While Balk’s research to date has largely focused on nanoporous materials and thin film coatings for improved electron emission, his newest area of research is the nascent field of high-entropy alloys.

This information has been sourced, reviewed and adapted from materials provided by Thermo Fisher Scientific – Materials & Structural Analysis.

For more information on this source, please visit Thermo Fisher Scientific – Materials & Structural Analysis.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.