Sintering, reaction bonding, crystal growth, and chemical vapor deposition (CVD) are the industrial processes used to make silicon carbide.

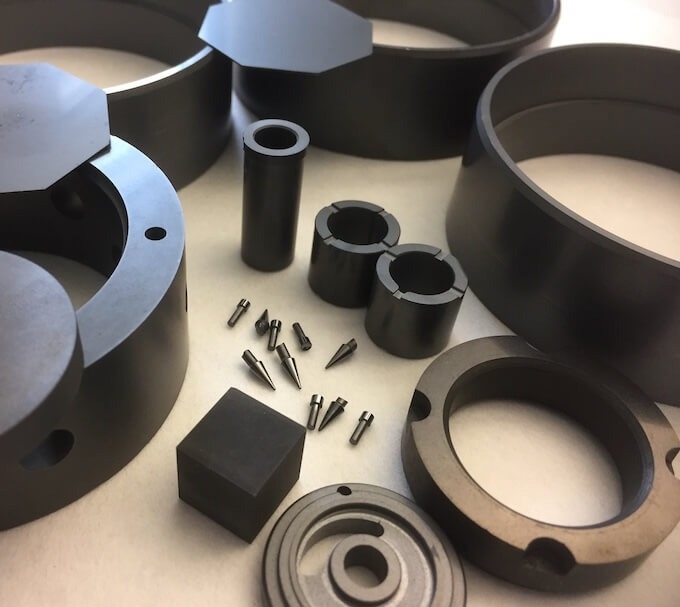

Image Credit: INSACO Inc.-Machining of Hard Materials

Low density, high stiffness, exceptional hardness, and wear resistance are all characteristics of silicon carbide. The CVD material can be developed with an electrical resistance as low as 1 Ω·cm, making it an acceptable conductor of electricity.

However, this electrical characteristic enables the fabrication of fine features using EDM techniques, which can be advantageous for generating tiny holes with high aspect ratios. Precise components generated from CVD SiC blanks must be completed using diamond grinding processes.

The comparatively high heat conductivity of silicon carbides is another intriguing quality. Once more, the CVD material outperforms cast iron and ordinary steel by attaining at least 150 W/mK. With increasing temperature, thermal conductivity does decrease, thus it must be carefully weighed against the needs of the application.

For many years, applications requiring strong thermal shock tolerance and resistance to erosion by high-energy plasmas have employed CVD silicon carbide in semiconductor fabrication.

All kinds of applications can benefit from CVD qualities, including electrodes and sputter targets, susceptors, gas distribution plates, chucks, heaters, edge rings, and any other application that needs electrical conductivity, wear resistance, and thermal shock resistance.

INSACO Inc. has fabricated precision components made from this material for many years. INSACO’s technology comprises diamond grinding of CVD silicon carbide in its extremely hard available state. Typically, INSACO will receive components from the most suitable producer and then produce them to satisfy the most stringent dimensional specifications of the customers.

Source: INSACO Inc.-Machining of Hard Materials

| Property |

Value |

| Mechanical |

| Density |

3.21 gm/cc |

| Hardness |

2540 Knoop |

| Modulus Of Elasticity |

68 x 106 psi |

| Flexural Strength |

67 kpsi |

| Poissons Ratio |

0.21 |

| Fracture Toughness |

2.7 - 3.3 MPa m½ |

| Thermal |

| Coefficient Of Thermal Expansion |

2.2 x 10-6/°C |

| Thermal Conductivity |

250-300 W/mK |

| Specific Heat |

0.70 cal/g °C |

All properties are at room temperature unless otherwise noted.

Engineering data are representative, and are not intended as absolute nor warrantable. Manufacturer’s Data shown is blended from multiple sources and therefore illustrates the marketplace.

This information has been sourced, reviewed and adapted from materials provided by INSACO Inc. - Machining of Hard Materials.

For more information on this source, please visit INSACO Inc. - Machining of Hard Materials.