Technical ceramics, also known as advanced or designed ceramics, are inorganic materials produced utilizing artificial raw materials in a regulated process to obtain homogeneity and enhance physicochemical attributes. They have great mechanical and electrochemical properties and are highly corrosion-resistant.

Image Credit: Dmetsov Alexey/Shutterstock.com

A Brief Overview of Technical Ceramics

Metals, polymeric materials, and refractory materials are being replaced by technical ceramics due to their toughness, chemical inertness, and high-temperature capabilities. This is one of the primary drivers of the market's expansion. Aluminum nitride, aluminum oxide, silicon carbide, silicon nitride, zirconia, and zirconium dioxide are among the highly popular technical ceramics utilized by various industries.

Market Trends and Forecast

Technical ceramics are used to manufacture components that are more robust, efficient, lightweight, and long-lasting for applications in a variety of industries. In recent years, both consumers and healthcare providers have increased their demand for technical ceramics used in the medical industry, resulting in a booming market. The expansion of this market may be ascribed to a variety of reasons, including an aging population, advances in medical technology, and rising awareness of the advantages of technical ceramics in medical device manufacturing.

In 2021, the market for technical ceramics around the world was worth US$ 74.92 Billion. IMARC Group predicted in its report that the market will be worth US$ 109.44 Billion by 2027, with a compound annual growth rate (CAGR) of 6.30% from 2022 to 2027.

In terms of revenue, the global medical ceramics market was expected to be worth $2.6 billion in 2022, as per the latest report by markets and markets. By 2027, it is expected to be worth $3.6 billion, with a CAGR of 6.6% from 2022 to 2027. The key driving factors include the growing need for medical ceramics in cosmetic procedures and tissue repair, the rise in demand for implantable devices, and the growing number of hip and knee replacement treatments.

Technical Ceramics in Medical Imaging

The thermal efficiency, tensile strength, and electromagnetic shielding of technical ceramics, along with innovative production techniques, provide dependable x-ray tubing and modules for medical imaging. Advanced ceramic materials provide superior dielectric strength and electrical resistance for power-intensive applications.

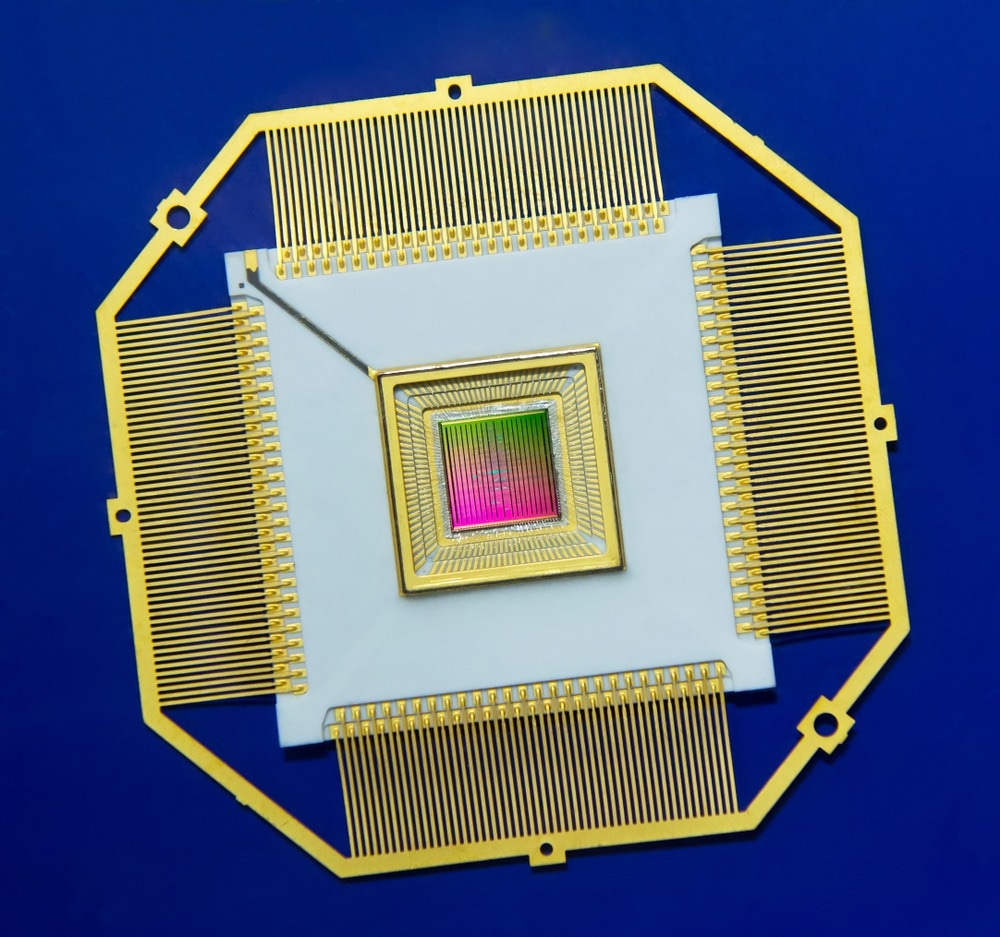

Scintillators for diagnostic imaging serve a crucial purpose in the detection of high-energy radioactivity in PET scanners and the conversion of light in CT scanners. For x-ray tubes and specialized imaging modules, technical ceramics are embedded to accommodate customer-specific designs.

Technical ceramics made from alumina (aluminum oxide, Al2O3) are extensively utilized due to their generally beneficial qualities and favorable price/performance ratio. Alumina ceramics are classified thus due to their alumina concentration, which ranges from 80% to over 99%. Higher-purity alumina exhibits better strength and corrosion resistance, resulting in a continuum of alumina grades, formulations, and capabilities.

Different diagnostic equipment, such as ultrasonic transducers and CT scanners, are also manufactured using technical ceramics. Technical ceramics are utilized in these devices due to their high absorption coefficient and structural strength, which enable the precise conveyance of ultrasonic waves. In addition, technical ceramics are capable of withstanding high temperatures and corrosive conditions, making them excellent for high-temperature and corrosive medical applications such as CT scanners.

Technical Ceramics Revolutionizing Electrosurgical Instruments

Technical ceramic materials compatible with USP Class VI are extensively utilized for electrosurgical activities, including ablation, cauterization, gastroenterology, arthroscopy, and laparoscopy tools. Technical ceramics provide bio-inertness, strength, exceptional dielectric properties, high-temperature electrical resistivity, minimum inherent intrusiveness, RF transparency, and almost no porosity.

Technical Ceramics in Medical Cutting Instruments

Due to the inherent wear resistance and strength of ceramic materials, blade durability and accuracy are significantly increased. Complete components and milling blanks are also eligible for precision machining. Technical ceramics for cutting blades and sharpeners offer several vital benefits, including a lifespan of up to 100 times that of conventional steel. Zirconia outlasts tungsten carbide by 20%. Electrical resistance with electrostatic discharge possibilities, damage tolerance, high strength, machining or sale as blanks, and extremely fine granular structures provide finishes less than 1μm.

Technical ceramic engineering and production tools enable unrivaled longevity and accuracy for cutting and sharpening devices, such as healthcare industry blades, capsule cutting tools (pharmaceutical), exacto-style blades and cutters, huge ceramic trimming blades, and knife sharpeners.

Polycrystalline YAG: A Revolutionary Technical Ceramic

High-purity Yttrium Aluminum Garnet (YAG) ceramics permit the creation of high-output, solid-state lasers that are essential to the operation of medical technology. YAG opto-ceramics have been created that eliminate many of the obstacles provided by YAG single crystals, hence giving maximum performance on a large scale.

For several dermatological purposes, YAG laser equipment and media are utilized to treat benign pigmentation lesions (tattoos), capillary legions, osteosarcoma, and skin malignancies. YAG laser media are utilized in a variety of ophthalmic procedures. They are frequently employed to treat posterior capsular opacification following cataract surgery, to generate a distal iridotomy in individuals with narrow angles or angle-closure glaucoma, and for many other purposes. Increasing the concentration and uniformity of dopants in YAG permits more control over optical characteristics.

Silicon Nitride: An Ideal Biomedical Technical Ceramic

Spinal implants are medical devices used to treat back pain and deformities caused by trauma, scoliosis, kyphosis, degenerative disc disease, and fractures. Four types of spinal surgeries use these implants: anterior, posterior, transforaminal lumbar interbody, and axial fusions. Silicon nitride has been used for over 30 years in spinal fusion surgery as porous intervertebral spacers and is known for its strength, resilience, reliability, and ability to encourage new bone growth.

Silicon nitride is also used in articulating devices such as knee and hip endo-prostheses due to its smooth and wear-resistant surface. In addition, silicon nitride can be used as a substitute for bone grafts in surgical procedures due to its biocompatibility and antibiotic properties. RNA-encoded synthetic regulatory circuits are being studied as a means to control cell behavior without genomic integration. Silicon nitride micro-tubes produced through strain-induced self-rolled-up nano-membrane technology are being used as a neuron cell culturing platform.

Technical Ceramics in Orthopedic Implants

Orthopedic implants, including knee and hip replacements, are among the most prevalent medical procedures that employ specialized ceramics. These devices are intended to replace broken or diseased joints and bone and necessitate materials with superior abrasion resistance, cytocompatibility, and a relatively low friction coefficient.

Technical ceramics such as zirconia and alumina are excellent for use in orthopedic implants. This decreases the likelihood of prosthetic wear and micro-plastic formation in the joint. In addition, technical ceramics are chemically stable, which means they are ideal for use in medical equipment that comes into direct contact with living tissue.

Recent Advances

Recent developments in the biomedical applications of technical ceramics have made them more viable for use in medical equipment that comes into close touch with live tissues. In the use of technical ceramics in medical devices, surface engineering has also assumed a prominent role.

Techniques like chemical vapor deposition, ionized blasting, and electrochemical anodization have been designed to improve the surface qualities of technical ceramics, therefore increasing their biocompatibility and decreasing the risk of implant refusal and wear. There have been major advancements in the use of technical ceramics in additive manufacturing for medical devices. 3D printing is becoming extremely prevalent in the medical industry, and technical ceramics are increasingly being used in 3D printing for medical devices.

In short, the domain of technical ceramics specialized for medical devices is expected to grow significantly, with Artificial Intelligence, IoT, and other Industry 4.0 products expected to play a vital role in its rapid commercialization.

More from AZoM: How are Bioplastics Made?

References and Further Reading

Corostek, 2023. Medical Device Components. [Online]

Available at: https://www.coorstek.com/en/industries/medical/medical-device-components/

Elan Technology. Ceramic Manufacturing in the Medical Industry. [Online]

Available at: https://www.elantechnology.com/ceramics/industries/ceramic-manufacturer-for-medical-industry/

Heimann RB. (2021). Silicon Nitride, a Close to Ideal Ceramic Material for Medical Application. Ceramics. 4(2). 208-223. Available at: https://doi.org/10.3390/ceramics4020016

Great Ceramic. Technical ceramics for medical use. [Online]

Available at: https://great-ceramic.com/technical-ceramics-for-medical-use/

Mathayi, J., 2022. Why Ceramics In Medical device & Components. [Online]

Available at: https://www.linkedin.com/pulse/why-ceramics-medical-device-components-john-mathayi/

Precision Ceramics USA, 2023. Ceramics in the Medical Industry. [Online]

Available at: https://precision-ceramics.com/industries/medical/

MarketsandMarkets. 2022. Medical Ceramics Market by Material - Global Forecast 2022 to 2027. Available at: https://www.marketsandmarkets.com/Market-Reports/medical-ceramic-market-237425129.html

IMARC. 2022. Technical Ceramic Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2022-2027. Available at: https://www.imarcgroup.com/technical-ceramic-market

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.