Artificial Intelligence is utilized in most industrial sectors to increase revenue generated and reduce processing time. Additive manufacturing or 3D printing has been on the rise and is the backbone of many major fields, such as the automotive sector, aerospace industry, sustainable construction, etc. The implementation of Artificial Intelligence (AI) for 3D printing has been the focus of research all over the world.

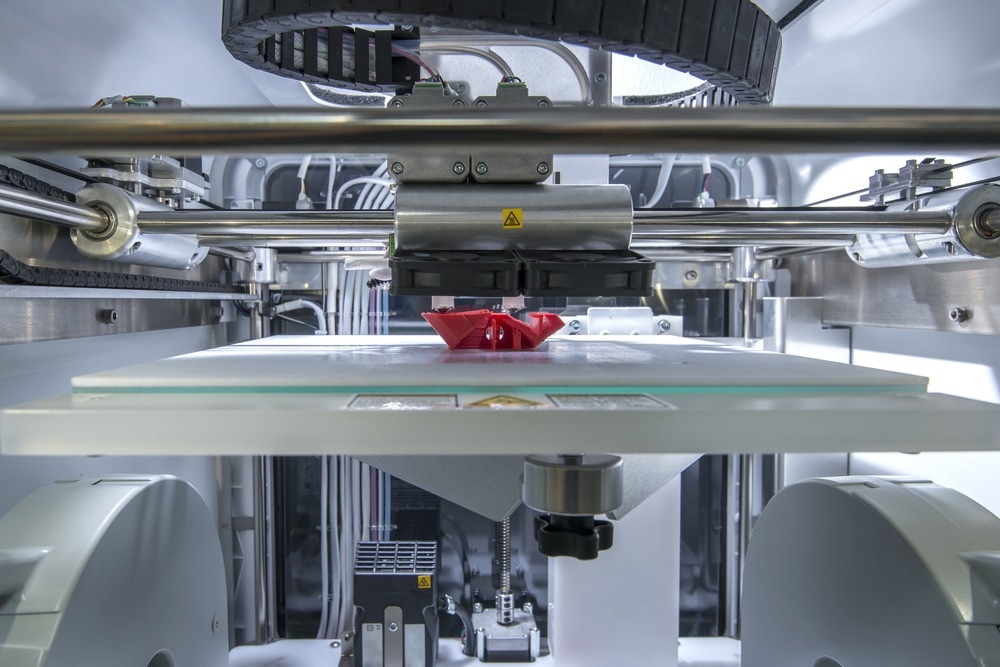

Image Credit: RomboStudio/Shutterstock.com

Industrial Utilization of AI for 3D printing

With the incorporation of AI into 3D printing, a massive transformation is anticipated in how companies tackle manufacturing and building operations. From product development to dispensation, AI technology can boost the whole supply chain. The capability for automating the printing process will also reduce the probability of human mistakes, a significant issue in output.

The potential of artificial intelligence in 3D printing is not restricted to the manufacturing and construction industries alone. Other industries, such as health, design, architecture, and aerospace, can also profit from the combination of AI with 3D printing.

Core Advantages of Utilizing Machine Learning for 3D Printing

The field of additive manufacturing is expanding quickly. Constantly, novel materials, technologies, and solutions are being created. From determining the optimum material for a certain work to boosting the construction quality of a product by eliminating human mistakes, machine learning (ML) is contributing to these developments.

Before a 3D-printed object can be employed for its intended purpose, it must be repaired for flaws such as holes and other imperfections. These difficulties can be automatically identified and resolved by ML. This saves time and money since it eliminates the need to reprint the entire product or spend hours manually mending each component.

The design may be optimized using machine learning by making tiny alterations based on experience. This may involve rethinking aspects that aren't functioning as effectively as they should or maximizing how sections fit together to produce a high-quality output. Predictive maintenance uses ML algorithms to forecast when parts require replacement or repair before total failure. This helps organizations plan and avoid losing money due to costly repairs or downtime while waiting for replacement components. Using machine learning, a company can utilize consumer data to create goods that meet their wants. In short, AI and ML offer a variety of advantages when utilized in junction with 3D printing.

Remote Detection of Faults with AI

The detection of faults during 3D printing is advantageous as it saves time and money. A novel AI-based computer vision methodology has been described in the journal Processes for assessing the quality of a Fused Filament Fabrication (FFF) 3D-printed item during the printing process.

By analyzing process-captured video, neural networks are constructed for spotting 3D printing problems throughout the printing process. During the printing process, defects are likely to arise in 3D-printed items, with stringing being one of them. These defects are typically associated with one of the printing parameters or the object's geometry. The fault stringing can be extensive and is often visible to the capturing equipment on the surface of the item. In this instance, an AI framework (Deep Convolutional Neural Network) was developed and implemented in a live context to perform detection processes and forecasts on a live video camera stream.

How AI-Enabled 3D Printing is Shaping the Future of Orthodontics

Similar to other professions, innovative digital technology has transformed the healthcare industry and orthodontic practice. Recent breakthroughs in artificial intelligence (AI) and 3D printing technology are valuable for enhancing orthodontic diagnosis and treatment planning, as well as for building algorithms and fabricating personalized orthodontic products.

AI has enormous promise for use in diagnosing dentofacial abnormalities and designing orthogenetic surgical procedures. A Convolutional Neural Network method demonstrated that orthognathic surgery considerably enhanced the profiles and aesthetic appeal of the majority of patients. AI technologies improve clinical accuracy for orthognathic procedures, treatment planning using 3D models (3D fabrication of operative orthotics), and therapy follow-up and picture superimposition.

AI-Based Printability Checker: A Game Changer

The 3D printing process is theorized to be capable of creating any 3D object. However, in comparison to conventional production processes, the development and utilization of 3D printing is still limited due to topological characteristics and distinctive material demands.

The latest article in the Journal of Basis Applied Science and Management System informs readers about the Printability Checker (PC) program, which determines if an object is appropriate for 3D printing or other production methods.

It consists of a feature extractor (FE), a printer manager (PM), and a verifier engine (VE). PC implements a judgment based on the findings of the criteria's complexity values. Calculating complexity is contingent on the selection of several indicators, such as tested runtime. In particular, the objective of FE is to retrieve the scientifically testable characteristics of a given 3D object. PM is responsible for managing printers using the applicable limitations and then sending the printer profiles to VE. In the meanwhile, VE may match the characteristics and limitations of FE and PM to verify the 3D object's printability based on the final complexity results.

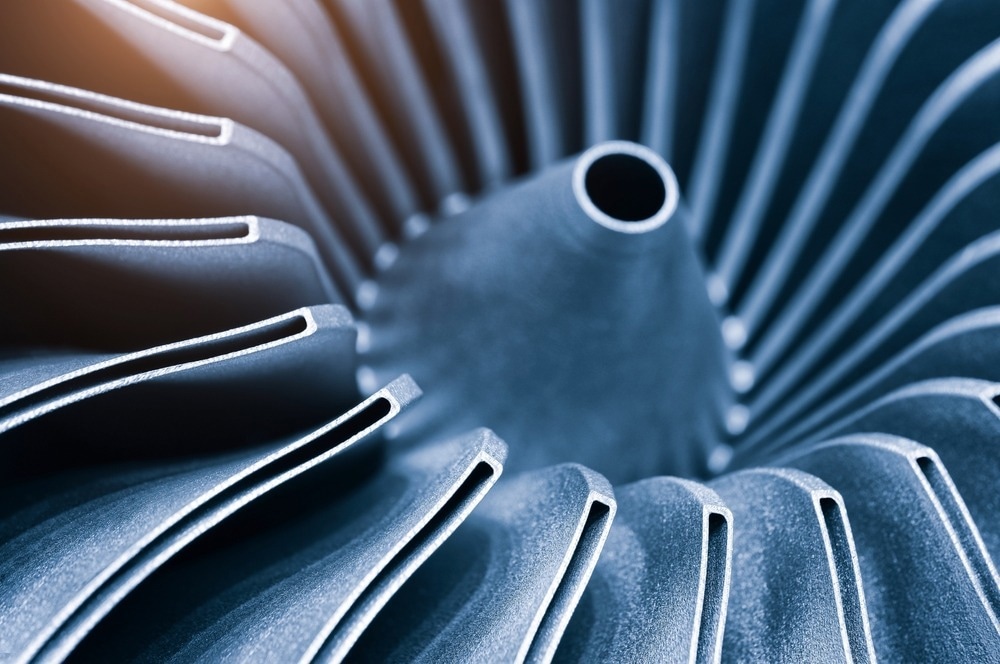

How is AI impacting 3D Metal Printing for Aerospace Parts?

The Journal of Physics: Conference Series focuses on the idea that the integration of Artificial Intelligence in 3D metal printing has been seen as a potential development and thus acts as a foundation for the advancement of aerospace technology.

Image Credit: Matveev Aleksandr/Shutterstock.com

The combination of 3D printing with artificial intelligence enables aerospace manufacturers to generate more accurate and precise aero components with increased design freedom at a lower cost and with less waste. Sensors and cameras are installed within a 3D printer, often near the nozzle where the powdered feedstock and laser beam are merged to form a solid layer, to provide in-process control and surveillance. The data is then sent to specialized software, which evaluates and interprets the various construction in real-time. Recognizing the issues and concentrating the power of Artificial Intelligence to solve them, the printers evolve as the process continues.

Novel AI-Based 3D Printing of Materials by MIT

MIT researchers have created a machine-learning algorithm to analyze and alter the 3D printing process in real-time to fix faults. Scientists and technologists are always inventing new materials with unique qualities that may be utilized for 3D printing. However, understanding how to manufacture these substances can be a difficult and expensive challenge.

Using artificial intelligence, MIT researchers have now streamlined this technique. The development of a ML system that uses computer vision to monitor the production process and fix material handling faults in real time. Using simulations, the researchers taught a neural network how to modify printing settings to reduce error and then applied this controller to a real 3D printer. The technology produced more precise prints than any previous 3D printing controller.

Challenges of AI Implementation in 3D Printing

Using ML approaches, data-driven numerical simulations are found to be more computationally efficient than physics-based numerical simulations.

In situ analysis and closed-loop regulation are highly dependent on computational effort. Due to the bigger data set, inspecting a pool with a high-speed camera demands more processing resources. This type of application using big data collection requires improved machine learning algorithms. The cost of computing is a significant barrier to the implementation of AI in additive manufacturing.

The exchange of data is crucial to the development of a huge database, which is required for the operation of ML algorithms. With more research groups focusing on the creation of novel materials and processes, standards for data gathering and pre-processing would ensure data sharing and promote collaboration within the AM community. Numerous ML frameworks are incompatible with one another. To enable the dissemination of ML models among the research community, it is crucial to establish a consistent framework. The lack of standards is a major issue requiring immediate steps to resolve this major concern.

The performance of machine learning (ML) algorithms is only as excellent as the quality of the input data. Sensing devices used in 3D printing procedures involving melting must have a fast refresh rate and excellent resolving power to gather information from melt pools. Despite the vast variety of sensors employed, each in-situ monitoring approach has limitations that hinder its application on a real manufacturing line.

Market Analysis

Fortune Business Insights have performed a thorough analysis of the global 3D printing market as well as the AI-automated 3D Printing industry. In 2021, the global market for 3D printing was estimated at USD 15.10 billion. It is anticipated to increase at a CAGR of 24.3% from $18.33 billion in 2022 to $83.90 billion in 2029, from 2022 to 2029.

The automated 3D printing market was valued at $706.69 million in 2021 and is projected to reach $5,878.56 million by 2027, expanding at a CAGR of 41.76% from 2022 to 2027. The market size for artificial intelligence in manufacturing is projected to reach USD 16.3 billion by 2027, expanding at a CAGR of 47.9% between 2022 and 2027 as per the latest report published by Research and Markets. The market is anticipated to expand at a forecasted rate due to the rising need for elements such as the enhancement of AI chipsets' computational power.

Future Perspective

Several steps are being taken to provide advantages to the additive manufacturing industry via the implementation of AI. Future research should concentrate on combining AI-based printability testing, slicing, and route planning to accelerate parallel slicing and optimize 3D printing paths. Using Service-oriented architecture (SOA) to increase the adaptability, integration, and personalization of 3D printing through a cloud-based design and production system is also an intriguing concept. Improving ML-based computational prefabrication (process planning) via exponential techniques, parallelization, and refinement of slicing algorithms will further open the road for fast global industrialization.

In short, the intersection of AI and 3D printing has emerged as a formula for success, with institutions all over the world investing in this particular domain.

More from AZoM: Improving 3D Printing Efficiency with the Variational Scale-aware Transformer (VST) Network

References and Further Reading

Fortune Business Insights, 2022. 3D Printing Market Forecast, 2022 - 2029. [Online]

Available at: https://www.fortunebusinessinsights.com/industry-reports/3d-printing-market-101902

[Accessed 5 February 2023].

Motalo, K. et. al. (2023). Evaluating Artificial Intelligence Effects on Additive Manufacturing by Machine Learning Procedure. Journal of Basis Applied Science and Management System. 13. 3196-3205. Available at: https://ssrn.com/abstract=4331452

Khan, M. I. et. al. (2022). Artificial intelligence and 3D printing technology in orthodontics: future and scope. AIMS Biophysics, 9(3), 182-197.

Research and Markets, 2022. Artificial Intelligence in Manufacturing Market by Offering (Hardware, Software, and Services), Industry, Application, Technology-Global Forecast 2027. [Online]

Available at: https://www.researchandmarkets.com/reports/5576700/artificial-intelligence-in-manufacturing-market

[Accessed 5 February 2023].

Paraskevoudis K, Karayannis P, Koumoulos EP. (2020). Real-Time 3D Printing Remote Defect Detection (Stringing) with Computer Vision and Artificial Intelligence. Processes. 8(11). 1464. Available at: https://doi.org/10.3390/pr8111464

Sokhach, D., 2022. Machine Learning For Smarter 3D Printing. [Online]

Available at: https://www.selfcad.com/blog/machine-learning-for-smarter-3d-printing

[Accessed 3 February 2023].

Syuhada, A. et. al. (2021). Incorporating 3D metal printing with artificial intelligence in meeting aerospace demands. In Journal of Physics: Conference Series (Vol. 1892, No. 1, p. 012015). IOP Publishing. Available at: https://doi.org/10.1088/1742-6596/1892/1/012015

Goh, G. D., Sing, S. L., & Yeong, W. Y. (2021). A review on machine learning in 3D printing: applications, potential, and challenges. Artificial Intelligence Review, 54(1), 63-94. Available at: https://doi.org/10.1007/s10462-020-09876-9

Zewe, A., 2022. Using artificial intelligence to control digital manufacturing. [Online]

Available at: https://news.mit.edu/2022/artificial-intelligence-3-d-printing-0802

[Accessed 4 February 2023].

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.