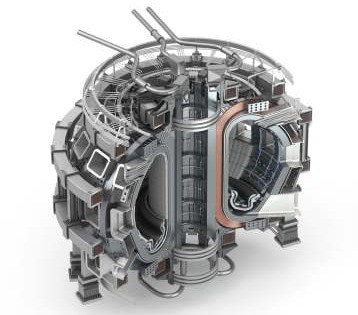

The innovative, next-gen DEMOnstration power plant, or DEMO, is “an industry- and technology-driven program, a key criterion for DEMO is the production of electricity,” state its designers. To ensure Tokamak port cells for a DEMO fusion reactor are managed appropriately, Technetics was approached by a client to design a seal and optimized assembly concept for a maintenance plan.

Image Credit: Adobe Stock

This is a challenging task as the seal’s performance must be able to:

- Capture high-energy neutrons from the reaction without melting the reactor walls

- Contain the plasma at high temperatures

- Ensure the plant is protected against corrosion caused by extreme temperatures inside the reactor core

- Maintain efficient operation of the plant through the prevention of pressurized steam loss, and

- Sustain a significant enough density of reacting ions

Failure is not an option as it would lead to the escape of radioactive materials, compromising the reactor core and causing significant damage to the Tokamak’s walls. Moreover, a system breach would bring about negative consequences that would harm human health and the environment. The client requires the expertise of an industry leader, for which Technetics could rise to the challenge.

Excelling the Future of Energy Through Technetics’ Advanced Sealing Technology

Port cells made of specially formulated concrete act as confinement barriers to protect the environment against radiation the reactor generates. The cells oppose the passage of neutrons and contamination.

While it is crucial to ensure the radiation remains confined, it is equally essential to allow access to the port cells to ensure maintenance and repairs of the interior reactor can be carried out.

Taking various approaches, Technetics is working in collaboration with the CEA to solve these technical challenges to improve the performance and longevity of the project. For example, Technetics offers a variety of engineering solutions to develop and maintain vacuum chamber sealing and oversee the design and development of specific components for the reactor, including vacuum seals.

Technetics provides ultra-high vacuum, irradiation, tritium environment, and remote handling solutions across the entire program. With a team of dedicated engineers to develop safety systems, cycle systems, and maintenance services, the aim is to ensure that the solutions perform as they should. Technetics is also committed to a complete, all-round engineering analysis and study for the four years of the program.

Image Credit: Adobe Stock

Technetics Provides Clients with Reliable Sealing Solution

Technetics delivers premier sealing services to support innovative technological developments across the client’s new DEMO Power Plant. The project demands industry-leading experts to ensure cutting-edge technologies are in place to develop a pioneering fusion reactor.

Delivering high-grade seals and maintenance for the Tokamak port cells, this Technetics client can rest assured they are working with a safe and efficient DEMO fusion reactor, which allows the focus to be on the primary goal of the technology: electricity production.

Technetics is proud to accept almost any challenge and deliver solutions to meet its customers’ needs.

Image Credit: Adobe Stock

This information has been sourced, reviewed and adapted from materials provided by Technetics Group.

For more information on this source, please visit Technetics Group.