AZoM speaks with Nathan Rich, Founder and CEO of IsoTruss, about the incredible material that is transforming industries and has won them a 2023 JEC Innovation Award.

Please can you introduce yourself and your professional background?

My name is Nathan D. Rich, and I’m Founder and CEO of IsoTruss, Inc. In 2015, I acquired the IsoTruss® brand and obtained its associated patent portfolio from Brigham Young University, and IsoTruss®’ inventor, Dr. David Jensen, Ph.D. I hold a Master of Business Administration focused on Finance & Entrepreneurship from Brigham Young University. While at BYU, I served as the Managing Director of Cougar Capital, an evergreen stage agnostic venture fund. Previously, I worked in corporate finance, and my family was involved in the large-scale industrial machinery business.

IsoTruss is a patented innovative composite material transforming many different industries. Could you describe what IsoTruss is in further detail?

Our mission at IsoTruss is to build the sustainable infrastructure of the future. Through ongoing innovation in R&D, engineering, design, and manufacturing, IsoTruss offers applications and solutions that are innovative, durable, and sustainable.

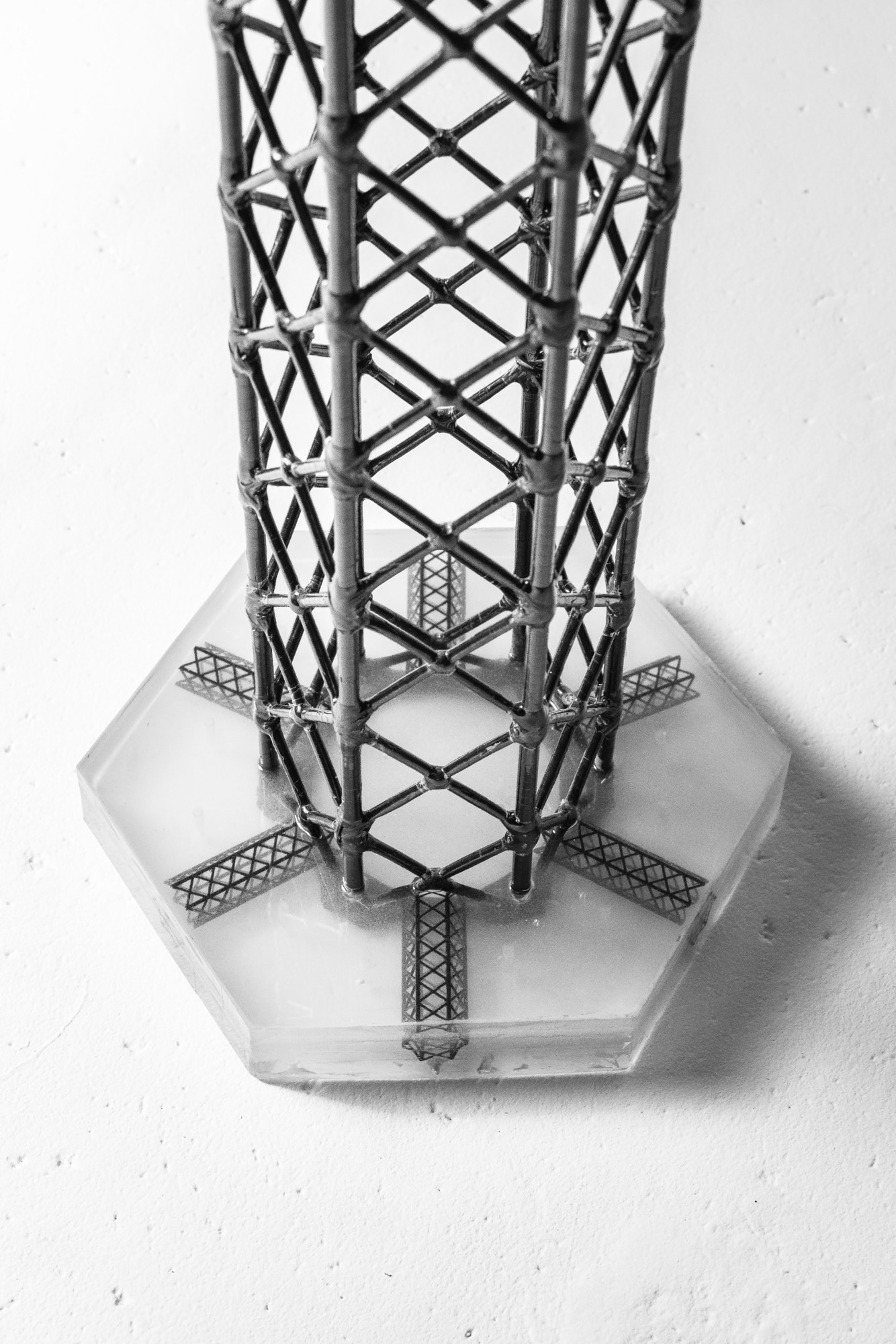

The IsoTruss® is a unique geometric configuration based on 2-dimensional and/or 3-dimensional equilateral or isosceles triangular sections comprised of unidirectional members fabricated with composite materials.

Image Credit: IsoTruss

Overall, the IsoTruss® combines high-performing continuous fiber (such as carbon, glass, aramid, etc.) reinforced polymer composite materials with a very efficient geometry to allow those elements to carry the load efficiently, allowing extremely lightweight and extremely high-performance structures.

What makes IsoTruss different from other materials on the market?

IsoTruss is different from other materials on the market because the technology is applicable across many industries, including aerospace, recreation, construction, and telecommunications infrastructure. The innovation in IsoTruss® technology is due to a combination of composite materials with the lattice structure. Composite materials are lightweight, stiff, durable, and corrosion-resistant. The IsoTruss® geometry further adds benefit to the composite materials by additional weight reduction, low drag force, and damage resistance. The reduced material use and increased product lifetime result in up to 70% reduction in CO2 emissions over the lifetime in certain applications.

How flexible to different applications is IsoTruss’s composite geometry?

The patented geometry coupled with advanced composites enables IsoTruss to build from a strong technology platform. In the telecommunications industry, the enterprise currently designs, engineers, and fabricates IsoTruss® lattice cell towers utilizing composite materials, most frequently with carbon fiber.

Image Credit: IsoTruss

In addition, IsoTruss, Inc. is doing research and development for applications and solutions in energy, with oil & gas pipelines, wind turbines, and utility poles; in aerospace, for aircraft and spacecraft; in architecture and construction, for concrete reinforcement utilizing IsoTruss® composite lattice structures instead of rebar for buildings and foundations, and in civil infrastructure, the potential with roadways, tunnels, and bridges. IsoTruss® designs are also utilized in sports equipment, including mountain bikes.

How is IsoTruss able to aid the shift toward sustainable infrastructure and construction?

Our IsoTruss® solution is exciting because it provides a path forward in building the sustainable infrastructure of the future, today. As mentioned above, through ongoing innovation in R&D, engineering, design, and manufacturing, IsoTruss offers applications and solutions that are innovative, durable, and sustainable.

With the continued focus on sustainability in telecom infrastructure investments, IsoTruss® towers significantly decrease the time, expense and environmental impact of heavy equipment and large installation crews required for equivalent steel cell tower build-outs, deliveries, and installations. Those reductions together decrease cell tower carbon emissions by 70% and substantially lowering the total cost of ownership (TCO).

Each IsoTruss® cell tower is designed and manufactured to meet the firm’s own rigorous design and production standards, various local, state and federal regulations, and Telecommunications Industry Association (TIA®) and AASHTO standards.

IsoTruss® cell towers, which are fabricated with corrosion-resistant composites, utilize patented geometry, which offers flexibility and modularity in structural design as well as superior wind resistance.IsoTruss® towers are engineered and tested to last at least 5 times longer than steel towers, which need to be replaced more often due to corrosion and other environmental factors. Consequently, the total cost of ownership (TCO) is lower, and on the environmental side, carbon dioxide emissions are reduced by 70% or more over the tower’s lifespan.

The IsoTruss carbon fiber tower has been named the winner of the JEC Composites Innovation Awards 2023. Please could you tell us about the tower and what makes it so extraordinary?

We were honored to receive the 2023 JEC Composites Innovation Award for our IsoTruss® carbon fiber tower. Our structures are innovative because they offer flexibility and modularity in structural design due to their particularly high strength-to-weight ratio, even over other composite structures.

Composites in general are lighter than steel, wood, and aluminum, but integration into the IsoTruss® lattice tower structure, which requires less carbon fiber material to fabricate, makes them even lighter, depending on the design for a particular site, and its specifications, thereby making IsoTruss® towers cost-effective versus steel towers. Consequently, the total cost of ownership (TCO) is lower, and on the environmental side, carbon dioxide emissions are reduced over the tower’s lifespan. This is due to the reduced material usage by twelve times on a weight basis, resulting in 70% reduction in carbon emissions over the life of the tower.

Our IsoTruss® tower solutions are well-suited to high wind, snow and ice environments in mountain settings and hurricane/typhoon-prone regions. This is mostly due to the corrosion-resistance of the composite material and the superior wind resistance of the IsoTruss® lattice geometry, which extends product lifetimes by five times over steel solutions.

Image Credit: IsoTruss

Composites are not common in the telecommunications industry which can create hurdles to adoption, but also makes IsoTruss products stand out distinctly from the competition. The IsoTruss advantage can be summed up in its mission statement: Build for Tomorrow. IsoTruss products are built to last even in harsh environments. Developed countries are more and more focused on sustainability, with many publicly traded companies required to report emissions data for operations and production of equipment and goods.

IsoTruss products fit well with these sustainability goals because they use less material and last longer than comparable steel. In developing countries, the corrosion resistance of composite IsoTruss is a significant draw, especially in areas that are humid, coastal, or prone to hurricanes or typhoons. An IsoTruss customer in the Philippines shared that its steel towers require replacement after only five years due to corrosion; however, IsoTruss towers could last fifty years or longer.

Image Credit: IsoTruss

IsoTruss products are also lighter weight than the competition. Weight advantages play into specific niches in the telecom market such as urban, rural, and mobile applications. The increase in tower density in urban areas comes from more signals on buildings such as rooftop towers. The weight of steel towers often requires reinforcement to the building which adds difficultly and cost to the deployment. IsoTruss towers, on the other hand, are light enough to install on rooftops without additional reinforcement to the building. In rural applications, transportation to and installation at deployment sites is particularly cumbersome, especially in areas with difficult access roads. IsoTruss towers can be transported with a light-duty truck or even maneuvered/carried by hand if needed. Mobile applications also benefit from lighter weight because they are frequently transported, assembled, and disassembled. Lightweight IsoTruss are a natural fit for mobile assets.

You are also exhibiting at JEC World – The Leading International Composites Trade Show in Paris this April. Why do you believe in-person trade shows and conferences like JEC World are so important?

In-person trade shows and conferences like JEC World are important because they provide an opportunity for IsoTruss to network with potential customers, partners, and suppliers. They also allow us to showcase our product and technology to a wider audience. In addition, in-person trade shows and conferences can be a great way to learn about new trends and technologies in the industry.

Sign Up for JEC World Here

Are there any key industries that IsoTruss is hoping to target in the coming years?

IsoTruss aims to target a wide range of industries in the coming years, including aerospace, industrial infrastructure, sports and leisure, and automotive. The company is currently focusing on telecom, defense, and industrial applications, but it sees potential for growth in other areas. IsoTruss believes that its patented technology can offer advantages in these industries, including strength and durability, lightness, and sustainability.

IsoTruss is confident that its products can help businesses and organizations in a variety of industries improve their performance and reduce their environmental impact.

What is next on the horizon for IsoTruss in terms of research and development?

R&D is essential to our company’s future as we develop new material applications, expand our product portfolio, and continually improve our manufacturing process. We’re committed to providing the best possible products and services to our customers as we work to provide the sustainable infrastructure of tomorrow.

About Nathan Rich

Nathan Rich serves as the CEO of IsoTruss, Inc. He is an experienced leader, skilled in entrepreneurship, finance, strategy, and management. Prior to founding IsoTruss in 2015, Nathan worked in the corporate finance department of Avery Dennison. He holds a Master of Business Administration focused on Finance & Entrepreneurship from Brigham Young University. While at BYU, Nathan served as the Managing Director of Cougar Capital, an evergreen stage agnostic venture fund. He is fluent in Portuguese, enjoys the outdoors and coaching his children’s youth teams. Nathan received a scholarship to play collegiate baseball at Rick’s College.

Nathan Rich serves as the CEO of IsoTruss, Inc. He is an experienced leader, skilled in entrepreneurship, finance, strategy, and management. Prior to founding IsoTruss in 2015, Nathan worked in the corporate finance department of Avery Dennison. He holds a Master of Business Administration focused on Finance & Entrepreneurship from Brigham Young University. While at BYU, Nathan served as the Managing Director of Cougar Capital, an evergreen stage agnostic venture fund. He is fluent in Portuguese, enjoys the outdoors and coaching his children’s youth teams. Nathan received a scholarship to play collegiate baseball at Rick’s College.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.