Since safety is a primary concern when operating nuclear power plant reactors, O-rings must withstand a high-pressure, high-temperature environment and provide an efficient seal within radioactive settings. Every 18 months, the O-ring seal must be replaced when conducting routine maintenance.

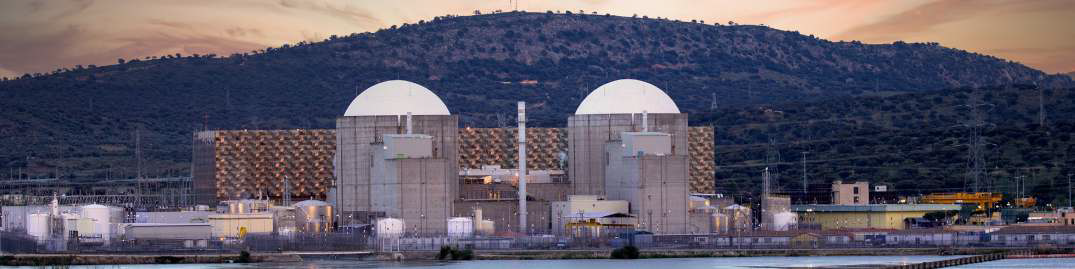

Image Credit: Adobe Stock

O-Ring Solution for Nuclear Power Plant Component Suppliers

As the largest known supplier in the industry, world-renowned, Korean-based, Doosan is an international and regional leader in manufacturing nuclear power plant (NPP) components.

The company is committed to delivering the highest standards. Doosan’s plant specializes in large-scale components, such as nuclear reactors and internal structures, nuclear reactor coolant pumps, steam generators, pressurizers, and many more.

Image Credit: Adobe Stock

Choosing a Reliable Provider

Given the recent increases in energy demand, Doosan set about developing a high-quality and reliable O-ring sealing solution.

Doosan determined that Technetics’ Reactor Pressure Vessel (RPV) O-ring would best fit its existing nuclear power plant (NPP) and new and cutting-edge projects.

Image Credit: Technetics Group

Discover more about Technetics’ RPV O-rings, and visit the website or contact a specialist for a bespoke solution for your given application.

This information has been sourced, reviewed and adapted from materials provided by Technetics Group.

For more information on this source, please visit Technetics Group.