Sponsored by PerkinElmerReviewed by Olivia FrostMay 5 2023

Sample preparation is critical in any analytical laboratory, accounting for almost 60% of the analytical timetable. The quality of sample preparation in a lab significantly impacts the following stages of analysis, including the quality of QA/QC testing.

Laboratories must consider the most recent advances in microwave digestion systems before purchasing. This article explores the primary considerations, advances, applications, and guidelines in microwave digestion.

The Basics

Sample digestion involves a chemical reaction for the digestion and leaves analyte ions suspended in the solution. Samples are typically heated to improve reaction times in a closed-vessel, microwave-aided digestion system.

This system generates the required pressurized, high-temperature environment to create a more rapid, complete sample digestion.

Temperature variation between vessels occurs due to different microwave absorption rates in samples, microwave field flux variabilities, microwave components, such as digestion vessels, and the chemical reactions during digestion.

As a result, more advanced microwave digestion systems that account for this variability must be considered.1

The Main Considerations of Microwave Digestion Systems

Examples of innovative design features that should be considered before the purchase of a system are as follows:

- Precise pressure and temperature measurements on each vessel

- Top-loading designs that have robust housing for further safety

- 32-position rotors that are straightforward to operate for a more rapid turnaround

- Integrated internal and possibly external cooling fan for digestion efficiency

- Fume collection system to avoid any exposure to hazardous fumes and system corrosion

- Vessel-type variability for specialized applications, e.g. permanently sealed and auto-venting options

- Capability for remote monitoring

- Intuitive software compliant with 21 CFR Part 11 and a preloaded cookbook of digestion methods for efficient operation

High-Throughput Microwave Digestion

32-position rotor options for microwave digestion systems, including the PerkinElmer MPS 320™, which offers two controlled 2.45 GHz magnetrons comprising 2000 W in total microwave power to heat samples to 260 °C to reduce digestion time and turnaround time.

This instrument improves post-digestion cooling with internal and external cooling fans that aid airflow inside the microwave cavity.2

Improved Safety Features

Ruggedized housing and top-loading design improve system safety by minimizing vessel failure due to operational error. Further safety features include a unique fume collection system that redirects venting from the microwave cavity to avoid operators being exposed to hazardous fumes.

Pressure hazards are also avoided through added safety features that auto-vent in a central fume collection system.2

Flexibility of Design

Alongside variable rotor selection, the selection of vessel volumes may be based on application to improve productivity. Systems such as the MPS 320 allow operators to choose systems based on vessel volume (50, 85, 100 mL) and rotor capacity (8, 16, and 32 positions).2

Direct Pressure and Temperature Control

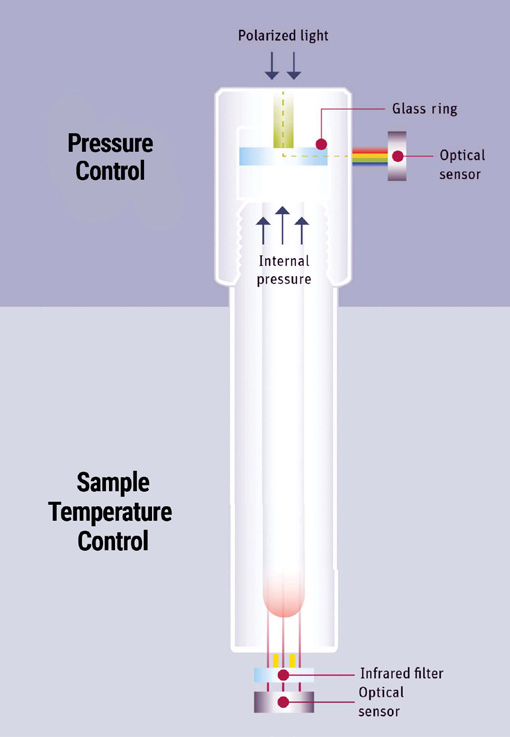

Unique microwave digestion systems, such as the PerkinElmer MPS 320, provide each vessel with Direct Pressure Control (DPC) and Direct Temperature Control (DTC).

DTC uses a non-contact mid-infrared sensor that enables reaction control via measurement of the sample material's real-time temperature as opposed to the vessel's surface temperature.

It modifies the microwave power according to this measurement while removing contamination and additional labor of contact-sensing devices.

Contact-free DPC technology employs a glass pressure ring (with a remote optical sensor in the vessel cap) and polarized light to measure and control changes in vessel pressure.2

Figure 1. Pressure and temperature control in the PerkinElmer MPS 320 Microwave Digestion System. Image Credit: PerkinElmer

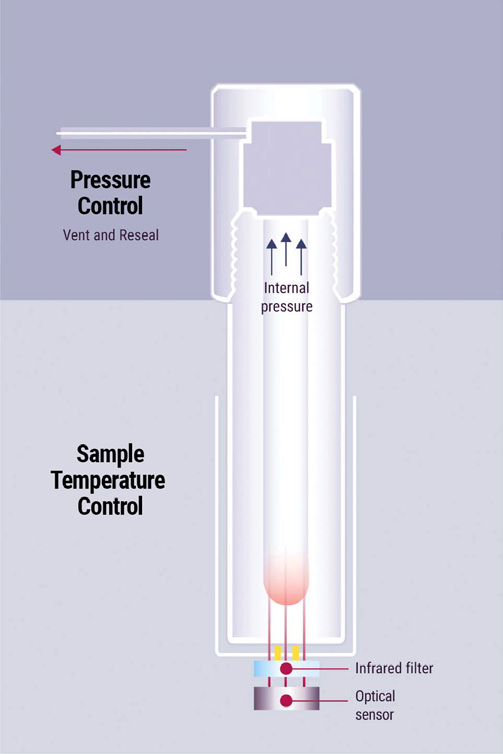

Auto-Venting Technology

Auto-venting technology enables further pressure control when the pressure exceeds the preset limits. This allows the continuation of digestion when the preset temperature is attained by maintaining the required pressure to reach suitably high temperatures while avoiding the risks of over-pressurizing the vessel.2

Figure 2. Auto-venting technology in the PerkinElmer MPS 320 Microwave Digestion System. Image Credit: PerkinElmer

Digestion Applications and the Preloaded Cookbook Advantage

Recent advanced microwave digestion systems are aided with pre-downloaded cookbooks containing digestion methods.

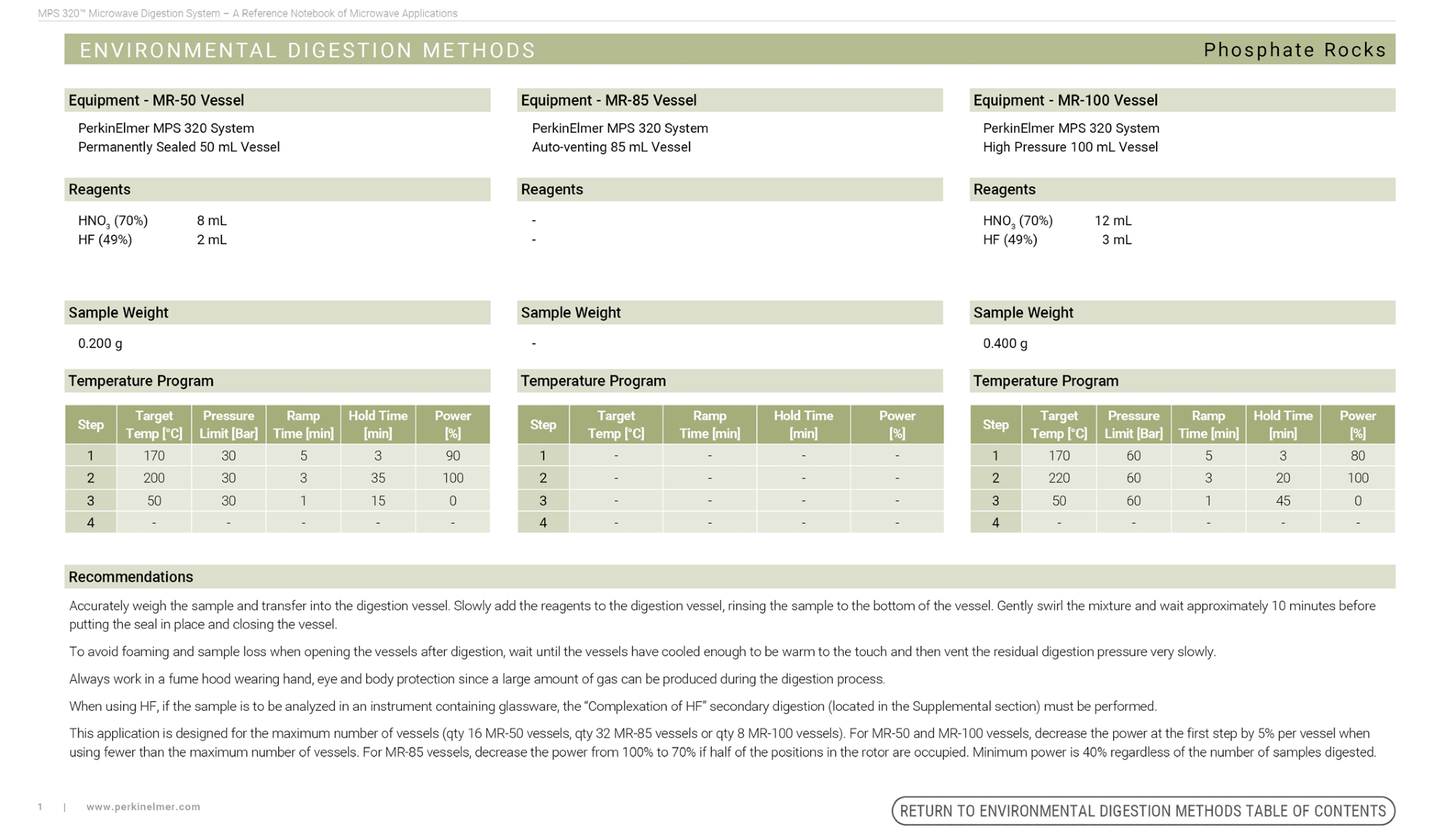

Microwave digestion systems, such as the PerkinElmer MPS 320, are equipped with cookbooks that provide a variety of digestion methods detailing vessel, equipment, sample weights, reagents used, program recommendations (such as target temperature, pressure limit, ramp time, hold time, and power), and more to guarantee successful digestion.1

The digestion cookbook provides methods for the following applications:

- Food and Beverage Digestion Methods

- Industrial Digestion Methods

- Forensic Digestion Methods

- Environmental Digestion Methods

- Pharmaceutical and Nutraceutical Digestion Methods

- Personal Care Product Digestion Methods

Figure 3. shows an example of an environmental digestion method in the MPS 320 Cookbook for phosphate rocks.1 Image Credit: PerkinElmer

Microwave Digestion Recommendations and Guidelines

Since microwave digestion has numerous applications, the considerable variability involved necessitates knowing many guidelines and considerations for the various typical digestion challenges.1

- Check that the digestion mixture sufficiently surrounds the sample.

- A pre-digestion venting step is advised before digestion.

- Decrease the sample weight or temperature of the method if the vessel pressure becomes too high.

- If the vessel temperature increases too rapidly, decrease the sample weight and increase the ramp time of the problematic step.

- If incomplete digestion takes place, consider modifying the ratio of acid to sample, increasing the temperature, or ensuring that adequate time is provided for the reaction to run to completion. Modifications will impact the temperature and pressure in the vessel.

- If sample digestion limits the utilization of HF, silicates and silicon will persist after digestion. Most analytes of interest may be extracted without using HF, and the remaining silica may be separated via centrifugation or filtration.

- When HF can be used, fluoride compounds may remain and appear milky or cloudy white. To integrate these solids back into the solution, a complexation of the HF step is required, along with the addition of bases to neutralize the solution for sample introduction systems comprised of glass.

- For preparations for arsenic (As) analysis by Hydride-ICP-OES or Hydride-AA, nitric acid alone may not place the As in a suitable oxidative state following digestion. If this is the case, use H2O2 to change the oxidative state of As to As V.

- Digestion of multiple platinum-group metals and metal alloys may occur in a solution consisting of three parts HCl and one part HNO3 by volume (often called aqua regia). This will lead to substantial gas formation, and the subsequent pressure considerations should impact the target digestion temperature and the sample amount.

- Hydrogen peroxide may be added to nitric acid digestion to increase oxidative strength. This will cause a rise in digestion pressures and possible rapid exothermic sample reactions.

- The most common digestion reagent is nitric acid since it does not produce interferences or spectral difficulties on most inorganic analytical instruments. It also exhibits robust compatibility in almost all sample introduction systems for inductively coupled plasma optical emission spectroscopy (ICP-OES), atomic absorption (AA), and inductively coupled plasma mass spectrometry (ICP-MS) instruments.

- A powerful alternative to nitric acid is hydrochloric acid. It is often utilized to digest oxides, metal alloys, or ceramic samples that do not respond well to nitric acid. However, hydrochloric acid can produce chloride salts that affect analyte recovery and create an extremely corrosive gas that may potentially damage instruments or cause polyatomic interferences in ICP-MS analysis or spectral interferences on ICP-OES.

- A powerful reagent, sulfuric acid, is occasionally utilized to digest plastic samples and challenge organic samples with multiple or cyclic bonds. Using sulfuric acid leads to multiple analytical challenges that must be overcome. If sulfuric acid is used, matrix matching to the sample is necessary.

- Phosphoric acid may sometimes be used to digest various geological and ore samples. Similarly to sulfuric acid, phosphoric acid has numerous potential interferences and will also impact the viscosity of the final sample solution.

Ensuring Microwave Digestion Efficiency

Microwave digestion is a vital technology for the preparation of samples. It produces reliable and accurate data early in the analytical testing workflow.

The key to optimizing sample preparation efficiency is ensuring that the most advanced and innovative microwave digestion system is employed. Selecting the right technology for a laboratory is crucial, as well as finding manufacturers that offer expert consultation.

Microwave digestion system manufacturers like PerkinElmer provide OneSource Laboratory Services for instrument support, compliance, and education services.

Acknowledgments

Produced from materials originally authored by Aaron Hineman at PerkinElmer.

References

- MPS 320 Microwave Digestion System Application Cookbook. PerkinElmer. https://pki.showpad.com/webapp2/results?query=microwave%20digestion&scope=content.coaching&slug=f9699d0c-15dc-41a6-b071-1abc0a4ab2f5.

- MPS 320 Microwave Digestion System Interactive Brochure. PerkinElmer. https://pki.showpad.com/webapp2/results?query=microwave%20digestion&scope=content.coaching&slug=0b46e973-2035-4727-960a-e473cc6b8501.

This information has been sourced, reviewed and adapted from materials provided by PerkinElmer.

For more information on this source, please visit PerkinElmer.