The compact natural gas contaminants analyzer, ABB’s Sensi+™, utilizes a unique tunable diode laser (TDL) technology named Off-Axis Integrated Cavity Output Spectroscopy (OA-ICOS).

Image Credit: ABB Measurement & Analytics - Analytical Measurement Products

This technology reliably, precisely, and simultaneously measures corrosive substances, including carbon dioxide, hydrogen sulfide, and water, instantaneously within intricate and time-varying natural gas streams.

A rapid response time is fundamental to enabling pipeline operations to take fast actions to process upsets.

Gas quality measurements are performed upstream from custody transfer connections. If an upset is detected, the gas must be rerouted before transfer.

A quicker response in the measure of contaminants allows a faster flow rate in the pipeline. This minimizes product waste, maximizes gas network uptime, and ensures productivity and safety.

With long cycle times, numerous conventional analyzers cannot update measurements promptly enough to detect rapid changes in contaminant gases.

TDLs can be quickly scanned to deliver measurement updates within seconds. However, despite all TDL-based analyzers claiming to have rapid measurement update times, they do not all offer a rapid response.

The measurement update time concerns how frequently the analyzer reports a new value based on the average number of cycles and the laser scan rate. However, the response time also concerns the time taken for the gas to flow through the analyzer and for a change to be registered to allow the end user to take action.

A method that is frequently used to attain faster response times is the utilization of high sample flow rates, but unfortunately, these high emission rates cause harm to the environment.

OA-ICOS is a cavity-enhanced method that involves laser light being bounced back and forth between highly reflective mirrors. Here, it is absorbed by contaminant gases over kilometers of effective path length in a physically compact gas cell at vacuum pressure.

This method enables extremely sensitive measurements to be made with a low-volume sample cell. This low volume allows low sample flow rates to still be utilized while reaching fast response times.

Sensi+ also measures various contaminants, which eliminates the waste of redundant emissions from each gas analyzer.

Commercial-grade plumbing components have “crevices” where trace amounts of some gases, such as H2S and H2O, can become trapped. As the temperature, pressure, or gas composition changes, gases are adsorbed or desorbed at differing rates, resulting in inconsistent measurements and a slow response to changes.

Sensi+ reduces this memory effect through custom-designed, machined, and treated components in the wetted path.

With a sample flow rate of less than 0.4 SLPM (0.014 SCFM), Sensi+ can measure H2S, H2O and CO2 simultaneously in real-time with rise (fall) times, as defined by IEC 61207, less than 10 seconds for H2S and CO2 and less than 35 seconds for H2O.

The measurement update time is less than two seconds, providing adequate time resolution during transitions.

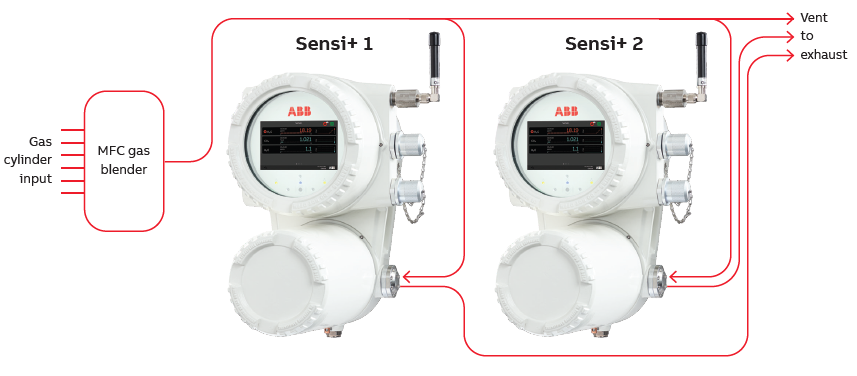

Figure 1. Experimental test setup using an MFC-based gas blender to make natural gas mixtures with high and low amounts of contaminants while two Sensi+ analyzers measured the resulting gas blend in parallel. Image Credit: ABB Measurement & Analytics - Analytical Measurement Products

Two Sensi+ analyzers were configured to measure the three gas contaminants to show the response time. These were installed in parallel to measure a natural gas stream while the contaminant gases were swapped between low and high values.

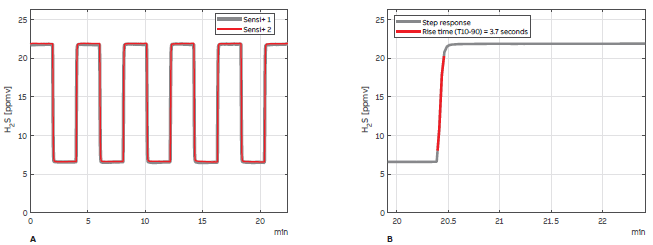

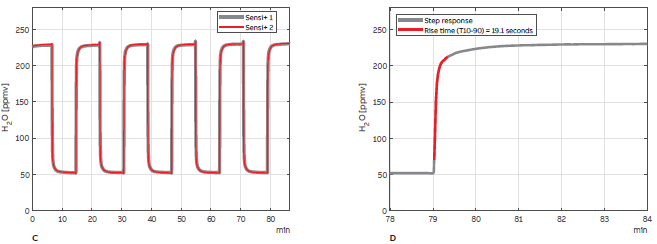

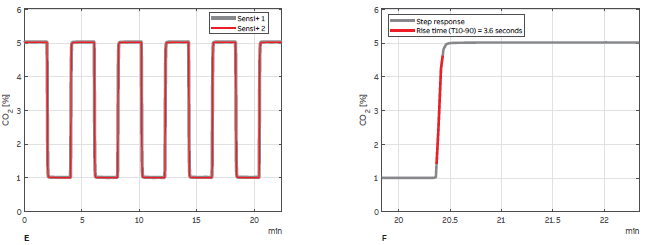

A custom, multiple gas blender based on mass flow controllers (MFCs) was employed to produce the natural gas mixture and change the volume of contaminant gas. Figure 2 displays the rise and fall of the measurement as the steps were repeated five times.

Figure 2. A, C and E show the instrument response from two Sensi+ analyzers while the gas mixture was repeatably switched between high and low amounts of H2S, H2O, and CO2. B, D and F show a closer view of the last response highlighting the portion of the response between 10% and 90% of the step change defining the rise time. Image Credit: ABB Measurement & Analytics - Analytical Measurement Products

Table 1 displays a summary of the recorded rise and fall times. Both analyzers responded consistently, rapidly, and repeatably, demonstrating that Sensi+ can maximize productivity and enable the user to take immediate action if required due to the rapid instrument response.

Table 1. Summary of the rise and fall times recorded for each instrument and each contaminant gas. Source: ABB Measurement & Analytics - Analytical Measurement Products

| Gas |

Fall/Rise |

Instrument |

Response 1 |

Response 2 |

Response 3 |

Response 4 |

Response 5 |

| H₂S (3.63 s avg.) |

Fall Time (3.65 s avg.) |

Sensi+ 1 |

3.6 s |

3.5 s |

3.5 s |

3.5 s |

3.7 s |

| Sensi+ 2 |

3.7 s |

3.6 s |

3.8 s |

3.8 s |

3.8 s |

| Rise Time (3.61 s avg.) |

Sensi+ 1 |

3.6 s |

3.2 s |

3.8 s |

3.8 s |

3.7 s |

| Sensi+ 2 |

3.6 s |

3.8 s |

3.8 s |

3.7 s |

3.8 s |

| H₂O (17.05 s avg.) |

Fall Time (16.17 s avg.) |

Sensi+ 1 |

14.7 s |

13.9 s |

14.4 s |

13.7 s |

14.3 s |

| Sensi+ 2 |

18.7 s |

18.5 s |

17.8 s |

18.1 s |

17.6 s |

| Rise Time (17.92 s avg.) |

Sensi+ 1 |

18.7 s |

18.8 s |

18.2 s |

18.1 s |

19.1 s |

| Sensi+ 2 |

18.2 s |

17.6 s |

17.1 s |

16.9 s |

17.2 s |

| CO2 (3.56 s avg.) |

Fall Time (3.53 s avg.) |

Sensi+ 1 |

3.5 s |

3.5 s |

3.4 s |

3.5 s |

3.3 s |

| Sensi+ 2 |

3.6 s |

3.7 s |

3.6 s |

3.7 s |

3.4 s |

| Rise Time (3.60 s avg.) |

Sensi+ 1 |

3.6 s |

3.5 s |

3.6 s |

3.2 s |

3.6 s |

| Sensi+ 2 |

3.7 s |

3.7 s |

3.8 s |

3.6 s |

3.7 s |

This information has been sourced, reviewed and adapted from materials provided by ABB Measurement & Analytics - Analytical Measurement Products.

For more information on this source, please visit ABB Measurement & Analytics - Analytical Measurement Products.