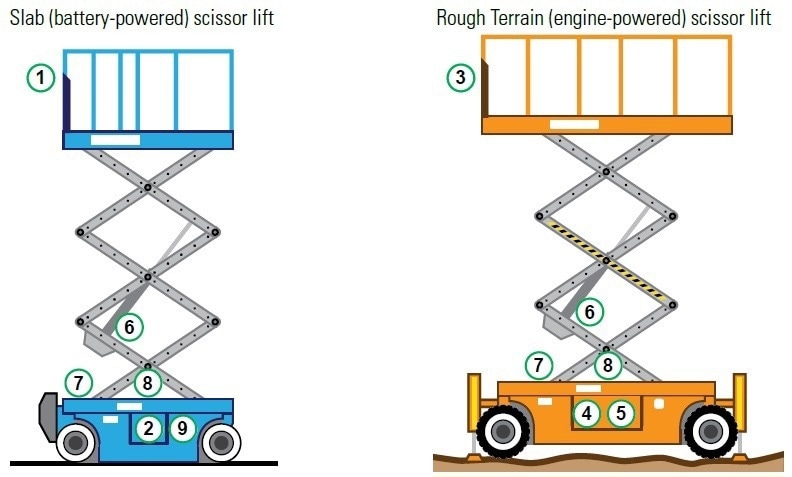

The most prevalent kind of Mobile Elevating Work Platforms (MEWPs) are self-propelled scissor lifts, which employ a scissor mechanism consisting of folding supports that move vertically in an 'X' pattern.

These lifts are divided into two main categories based on their power source and intended usage. Battery-powered (or electric) scissor lifts are commonly used indoors on level surfaces, while engine-powered lifts are typically used outside on uneven terrain (hence their designation as 'rough terrain' lifts).

Regardless of their power source, self-propelled scissor lifts are equipped with numerous sensors and controls to regulate their movements, ensure safety, and, most importantly, maintain stability (as operators on the platform are susceptible to fall hazards, safety is of utmost concern).

Rough Terrain (engine-powered) scissor lift. Image Credit: Sensata Technologies, Inc.

Slab (battery-powered) scissor lift. Image Credit: Sensata Technologies, Inc.

Solution

Operator Controls

Sensata has been a leading supplier of complete platform control systems for scissor lifts powered by either batteries or engines for several decades.

The control systems consist of a platform control unit and an electronic control unit (or a ground control unit for engine-powered lifts) that can connect and manage various digital and analog machine interfaces, such as joysticks, sensors, limit switches, motor controllers, pushbuttons, and alarms, through a dedicated CAN-bus system.

The latest K610 generation of scissor lift controllers features an open-source platform, CoDeSys, that allows manufacturers to create custom functionality for their lifts.

Motor Controls

Sensata's M700 motor controller is a high-power hydraulic pump that provides fully programmable control of DC series wound motors. It employs microprocessor-based logic with programmable parameters, providing maximum flexibility at a minimal cost. Both hardware and software are redundant to ensure reliability.

Sensors

Sensata can also provide a comprehensive range of primary sensors, including the PTE series high-pressure sensor that regulates the hydraulic pressure of the main cylinder, the 9360 series angle sensor used to determine platform height, and the T series inclinometer, or other suitable sensors, used to monitor the chassis inclination for safety purposes.

By combining the pressure and angle sensors, the platform overload condition can also be controlled, which is crucial when it comes to ensuring compliance with the ANSI 92 and EN280 safety standards.

Related Products

Table 1. Source: Sensata Technologies, Inc.

| Reference on Diagram |

Product |

Features |

Function |

| 1 |

|

P610 |

- 3 Analog Inputs integrated

- IP65

- USB

|

Platform Control Unit |

| 2 |

|

E610 |

- 2 CAN, 2 USB

- 40 input/output

- Multi-language,

- Large LCD display

|

Electronic Control Unit |

| 3 |

|

PCU100 |

- Extensive integrated controls

- IP65

|

Platform Control Unit |

| 5 |

|

GCU120 |

|

Ground Control Unit |

| 6 |

|

PTE7100 |

- High pressure

- MSG (Micro Silicon Strain Gauge)

|

Pressure Sensor |

| 7 |

|

9360 Series |

|

Angle Sensor |

| 8 |

|

T Series |

- High resolution 0.01°

- High accuracy 0.1°

|

Inclinometer |

| 9 |

|

M700 |

- Pre-charge control

- Redundant design hardware and software

- Short duration boost capability

- Can communication to ECU

|

DC Motor Controller |

General Diagram

Image Credit: Sensata Technologies, Inc.

This information has been sourced, reviewed and adapted from materials provided by Sensata Technologies, Inc.

For more information on this source, please visit Sensata Technologies, Inc.