Voice coil actuators (VCAs) are becoming increasingly useful for precise motion applications as the demand for smaller and more accurate linear motion control components grows.

These actuators are being used in an increasing variety of mission-critical equipment, from ventilators that help patients breathe to guiding the arms of asteroid-collecting spacecraft.

Initially developed for audio speakers, voice coil actuation technology is now utilized in a broad range of medical, industrial, and space applications to provide dependable and accurate motion control.

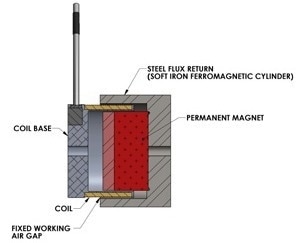

Despite being in existence for many years, VCA technology, illustrated in Figure 1, remains a mystery to numerous design engineers. This is because, until recently, the range of application areas in which it was a cost-effective solution was somewhat limited.

In the past, solenoid-based devices were a more common choice for designers, despite their limitations in flexibility. However, with the availability of powerful MCUs and efficient drivers, advanced linear motion designs using VCAs have become easier and more affordable to implement.

When developing a product that requires dependable, repeatable, and controllable motions, engineers should consider using VCA technology.

Voice coil actuators provide numerous benefits to the engineer. VCAs are simple and highly robust while also offering exact precision based on their input. VCAs accelerate smoothly and quickly to any position within their stroke with nearly zero hysteresis and are only limited by the system’s position-sensing precision and driver capability.

Due to their high accuracy, these devices are particularly well-suited for applications such as medical devices, robotics, and industrial process equipment..

Figure 1. Linear Voice Coil Actuator. Used in a wide range of medical and industrial applications, an axial voice coil actuator is composed of a permanent magnet situated within a moving tubular coil of wire, all inside of a ferromagnetic cylinder. When current runs through the coil, it becomes magnetized and repels against the magnets, producing an in and out, back-and-forth motion. Image Credit: Sensata Technologies, Inc.

Staying Alive - Precision Control in Medical Devices

The medical industry is one field that requires critical precision, particularly in devices such as drug-dispensing pumps and ventilators. These devices cannot rely on approximations, as every microliter of liquid or air must be precisely measured and managed.

A VCA-based solution provides accurate motion control in a medical flow-management system without added complexity or bulk.

Designing medical devices presents challenges that go beyond meeting performance and regulatory standards. This demand for performance in a constrained space lends well to a VCA solution.

The demand for high performance in a limited space makes VCA technology an ideal solution. Specifically, linear voice coil actuators can be designed to meet the precise motion control requirements and ultra-small size needed in the medical industry.

These miniature VCAs are commonly utilized to regulate inhalation and exhalation valves on ventilators, ensuring the precise amount of air specified and the necessary reliability for critical life-saving applications (Figure 2).

Figure 2. VCAs such as Sensata’s LAH08-15-000A are often used to control inhalation and exhalation valves on ventilators as their precision, reliability, and small size meet the demands for life-critical applications in the medical industry. Image Credit: Sensata Technologies, Inc.

Another advantage of these types of VCA motors is their bi-directional capabilities, permanent magnets, and magnetic latches. These features enable the VCA to remain in position at one end or the other of a stroke during a power failure, ensuring that valves stay open or closed in the case of a power outage.

These compact VCAs have a diameter of just 0.75” and weigh 2.3 ounces. Yet, they can provide a peak force of nearly two pounds in an operating stroke of ±2 mm with low hysteresis, zero cogging, high acceleration, and a long-life cycle.

The precise linear motion control provided by VCAs can also be used in other precision medical systems, such as anesthesia machines, ultrasound probes, blood analyzers, and laboratory equipment.

Out of this World - Fail-Safe Operation on Spacecraft

Equipment utilized in military and aerospace sectors must maintain a high level of precision regardless of the environmental conditions. Therefore, the equipment must be both durable and precise, akin to the medical industry.

In such scenarios, customized solutions can aid in ensuring that all specifications necessary to achieve the desired performance are accounted for during the initial equipment design phase.

To address the unique requirements for a space-based application, Sensata engineers designed a moving magnet VCA that was able to withstand the harsh requirements for a spectrometer moving mirror on the Origins-Spectral Interpretation Resource Identification Security Regolith Explorer (OSIRIS-Rex) spacecraft.

The OSIRIS-Rex was launched in September 2016 to work alongside the Asteroid Bennu in 2018 and bring samples back to Earth in 2023.

The custom-made moving magnet VCA was affixed to the moving-mirror assembly of the OSIRIS-Rex Thermal Emission Spectrometer (OTES) to accurately position it for surface scanning as the spacecraft approached the asteroid. The customized VCA was manufactured to ensure dependable and fail-safe operation, with an emphasis on reliability.

The actuator design necessitated redundancy technology, low-outgassing, and precise motion control positioning for optimal performance.

Staying within a specific size, weight, and power limit was crucial for the spacecraft due to the limited space available. These limits were met by designing a compact housing that measures around 2” in diameter and 3” in length.

To meet the need for near-zero emissions, Sensata developed the actuator using mechanical assembly methods and spaceflight-approved materials while minimizing the use of adhesives and inks. This approach ensures a clean manufacturing process that eliminates substances that could cause outgassing.

Moreover, the actuator was equipped with high-energy Neodymium Iron Boron magnets to enhance its operating efficiencies.

The custom magnet solution and clean assembly methodology were applied to a range of actuators with different sizes, resulting in the production of high-performance VCAs measuring 12‒65 mm in diameter and 12‒75 mm in length (at mid-stroke) and are suitable for various applications, such as semiconductor, military, space, and test and measurement. (Figure 3)

Figure 3. High-precision voice coil actuators like Sensata’s model LA05-05 meet the high purity and low outgassing requirements for semiconductor, military, and space applications. Image Credit: Sensata Technologies, Inc.

Smooth Operations - Low Friction in Industrial and Processing Applications

The transportation of items from one location to another is a widely used application, but it is not always as straightforward as connecting a motor to a conveyor belt.

In numerous continuously operating applications, inconsistent motion resulting from excessive friction can lead to profit loss and create defects in work that reduce yields.

For such applications, VCA solutions that demonstrate extremely low hysteresis and friction while offering precise and consistent bi-directional position control, such as the VCA depicted in Figure 4, are optimal.

Key to the VCA’s low-friction design is a symmetrical flex circuit that stops any friction caused by movement coupled with a solid brass ball cage to reduce it further.

This design achieves an operating performance with a hysteresis of only 10 mN compared to similar-style actuators that can deliver up to 50 to 200 mN. Additionally, the VCA offers other performance attributes such as a peak force of 4.7 N, a total stroke of 7.4 mm, and a compact size of just 38 mm in diameter by 48.3 mm in length.

Figure 4. VCAs deliver low hysteresis/low friction for reliable and precise motion control in a compact package. Image Credit: Sensata Technologies, Inc.

Bringing it Together- Tools to Speed Up Development

Design tools that assist engineers in comprehending and implementing a particular technology are crucial for its adoption, and VCAs are no exception.

Self-contained kits, such as Sensata’s Voice Coil Actuator Developer’s Kit (Figure 5), include a VCA with a built-in feedback sensor and a programmable controller with motion control software that is compatible with PCs.

These kits enable users to leverage the benefits of VCAs without the need to specify the electronics required for a complete control system.

This type of tool can help designers quickly develop an actuation system and demonstrate a working design with velocity, position, force, reciprocation, and acceleration control to address nearly any application.

Figure 5. Self-Contained Voice Coil Actuator Developer Kits enable designers to quickly evaluate and implement a VCA-based motion solution. Image Credit: Sensata Technologies, Inc.

Moving Forward with VCA Technology

The capability to incorporate advanced and precise linear motion in any space is now possible, empowering both existing and new applications that were previously not feasible due to cost or complexity constraints.

For example, a VCA built into an electric-vehicle charging system could raise and align the coil from the floor to the one at the bottom of the vehicle for optimum energy transfer or on printer-head positioning in a high-resolution 3D printer.

The applications of VCA technology continue to expand as engineers use it to address complex, delicate, or sensitive motion applications.

The key to success is to identify and create the appropriate solution for the particular application, leveraging the strengths of the technology and the user’s needs.

This information has been sourced, reviewed and adapted from materials provided by Sensata Technologies, Inc.

For more information on this source, please visit Sensata Technologies, Inc.