Based on the recently published article coauthored by Alan Garza, Sam Miller, and Scott Sutherland, Discussing LNG: Adapting to a more strategic role calls for effective quality analysis, this article will delve into the main points of discussion relating to Hydrocarbon Processing and the use of analyzer technology for LNG transport.

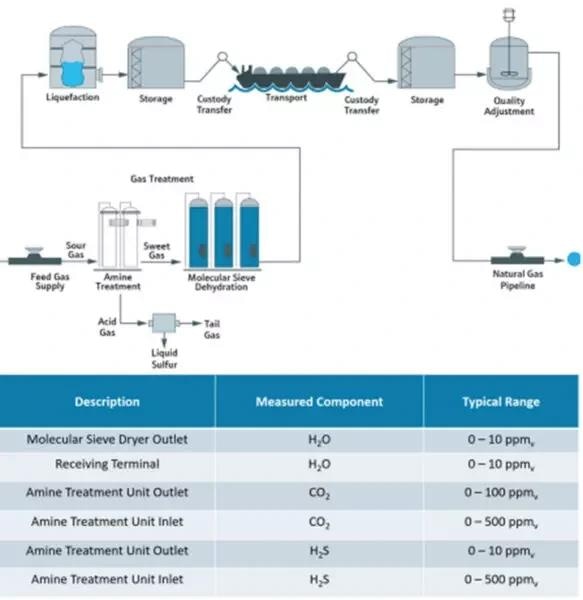

Natural gas must be treated before liquefaction to remove containments that can condense at cryogenic temperatures or damage equipment. Image Credit: Endress+Hauser

As the disruption of the global hydrocarbon supply chain increases, liquefied natural gas (LNG) has become an important topic for buyers and sellers looking to satisfy energy needs.

LNG is transported around the globe an a daily basis, comes from a variety of sources, each with unique characteristics, and is worth billions of dollars.

To ensure the optimal processing of natural gas before liquefaction and to detect any loss in value during prolonged transit periods, the implementation of analyzer technologies is crucial.

New techniques offer enhanced accuracy and reliability in measurements while reducing lifetime costs and maintenance requirements.

This article will compare how traditional Gas Chromatography and Raman Spectroscopy differ when it comes to evaluating LNG through its production chain and verifying its suitability for pipeline use after pretreatment.

Pretreatment and Natural Gas Liquification

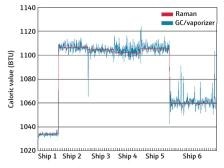

Variability with the sample vaporizer results in erratic BTU readings from the GC. Image Credit: Endress+Hauser

Liquefied Natural Gas (LNG), when compared to locally produced gas, exhibits reduced levels of contaminants as a result of their removal during an extensive pretreatment process.

The pretreatment stage involves the handling of contaminant levels that necessitate the implementation of tunable diode laser absorption spectroscopy (TDLAS) analyzers at transfer points throughout each phase.

These TDLAS analyzers serve to validate the efficacy of the catalyst and the overall pretreatment process by assessing the contamination levels in the gas before proceeding further into the liquefaction process.

Following the completion of pretreatment, the gas progresses to the liquefaction stage and subsequently onto the designated transportation mechanism.

LNG Transport

Afterward, the natural gas undergoes liquefaction and is subsequently loaded onto a vessel. Upon reaching the shore, the liquefied natural gas (LNG) is transferred to a storage tank to undergo regasification before being introduced into the pipelines.

LNG changes while in transport; it boils off its light components, causing them to escape into the tank.

The typical LNG tank load can have a value of up to $50 MM or more; a change of even 1% is worth $500,000. Thus, basic contaminant levels and calorific values must be verified. The challenge at this point in the process is finding an analyzer technology suited to the application.

Traditional Gas Chromatography (GC)

When it comes to the analysis of natural gas after the pretreatment stage, Gas Chromatography (GC) is the conventional method of choice. In this method, a sample of the natural gas is mixed with an inert carrier gas and passed through a packed column enclosed in an oven.

Gas Chromatography can be quite complex. Typically, the analyzer is placed near the source because it depends on a sampling system to deliver gas to the analyzer. Due to the need for an ongoing supply of carrier and test gases for calibration, this can also become costly.

To perform GC analysis, an LNG sample needs to undergo vaporization to convert it into a gaseous form suitable for analysis.

The vaporizer stage is usually more problematic than the analyzer itself, so it is vital to monitor this stage to ensure that it does not lose the lighter fractions or stop the process while some of the heavier fractions remain partially liquefied.

The basic challenges while using GC analyzers are:

- Requires daily calibration performed by feeding a premeasured test gas into the analyzer.

- Requires consumables and taking analyzer offline.

- It can be operationally complex.

- It can maintain measurement accuracy, but it does not solve the larger issue at hand.

- It can provide highly precise analysis, but if a sample is not representative of the LNG composition, then the underlying problem remains unresolved.

- Requires the LNG to be converted into gas for analysis.

- The analyzer must be near the source due to the tubing and valving at a limited distance.

Raman Spectroscopy

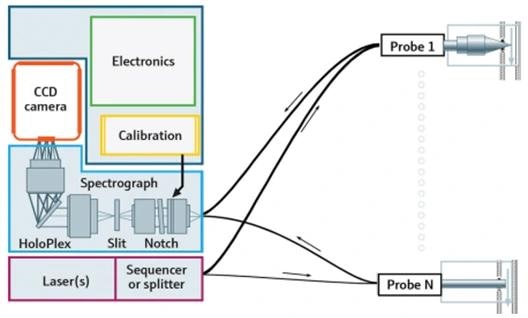

Several gas and liquid analysis technologies have been developed based on the laser's capability to generate highly precise wavelengths of light. Raman Spectroscopy, for instance, employs a laser to generate light within the visible or near-infrared spectrum.

As molecules interact with this light, their molecular bond vibrations become excited, leading to a scattering effect that causes the laser light to scatter into different wavelengths.

The ability to insert a probe directly into the LNG stream eliminates the need for a traditional handling system. Image Credit: Endress+Hauser

A Raman analyzer is designed to detect and measure these specific wavelengths and their intensities, enabling the creation of a chemical profile for the sample. In the case of LNG analysis, a probe is inserted into the pipeline to analyze the flowing gas or liquid.

The probe emits laser light into the LNG sample, and the resulting Raman light is collected through the same probe tip.

Subsequently, the collected Raman light travels through a second fiber-optic cable and enters a detector within the analyzer. In the detector, the individual wavelengths are identified and quantified to provide valuable analytical information.

Using this approach results in several critical advantages when compared to GC analysis, including:

- The probe inserts directly into the LNG stream, taking the reading in-situ, with the moving liquid constantly refreshing the sample.

- Measuring LNG in-situ means that there is no vaporizer and no need for sample transport lines, valves, heaters, or regulators.

- A single analyzer can be connected with up to four probes so that readings can be taken at multiple locations in the process stream.

- Output from the probe changes in real-time, and the analyzer can take a snapshot of the composition in less than 10 seconds with no delay between readings.

- Measures stream up to 500 meters from the analyzer, with no lag time, using cryogenic Raman optical immersion probes and industrial fiber optic cables.

- Operates virtually maintenance-free, ensuring that the analyzer is ready any time measurements are needed.

- It can operate for up to 2 years without needing to be calibrated.

This information has been sourced, reviewed and adapted from materials provided by Endress+Hauser Ltd.

For more information on this source, please visit Endress+Hauser Ltd.