Lancaster University is home to one of the UK’s most robust nuclear centers within a university setting, acknowledged internationally for its capabilities. Presently, a postgraduate researcher, Joshua Findley, is examining thermodynamic measurements of materials designated for next-generation nuclear reactors.

Image Credit: ShutterStock/vlastas

He has inherited a Hitachi STA7200. Obtained by the university in 2015, this instrument has seen limited use since its acquisition. To restore its functionality and utilize it for collecting novel data essential for research publication and his doctoral completion, Joshua reached out to Hitachi’s customer support team for aid.

A Multi-Functional Thermal Analyzer

The STA7200 is a versatile thermal analyzer that combines thermogravimetric analysis (TGA) and differential thermal analysis (DTA) into a single device, enabling simultaneous measurements. Despite being acquired in 2015, Lancaster University’s STA7200 had been used sporadically, primarily for thermogravimetric testing.

Before Joshua’s tenure began in 2021, the DTA capabilities of this instrument had not been explored. Joshua approached his work with confidence, based on the STA7200’s reputation for precision and accuracy, as endorsed by his fellow researchers.

Whilst I didn’t choose the instrument myself, I was told the TG application on the STA7200 is second to none.

Joshua Findley, Postgraduate Researcher, Lancaster University

Developing the Next Generation of Nuclear Power Plants

Joshua’s research focuses on the examination of the fusion behaviors of various molten salts using the STA7200. He aims to understand their melting behaviors, including liquidus, solidus, and solid-solid phase diagrams. The goal is to assess how molten salts can be used as the primary coolants in the next generation of nuclear power plants.

Molten salts offer advantages such as low vapor pressure and a high boiling point, allowing reactors to operate at high temperatures and low pressures, enhancing efficiency and safety. A comprehensive understanding of the melting and cooling behaviors of these salts is vital for gauging their practical effectiveness.

Equipped with the STA7200, Joshua can precisely determine the melting and crystallization temperatures of his molten salts and accurately measure the heat capacity of different molten salt variations.

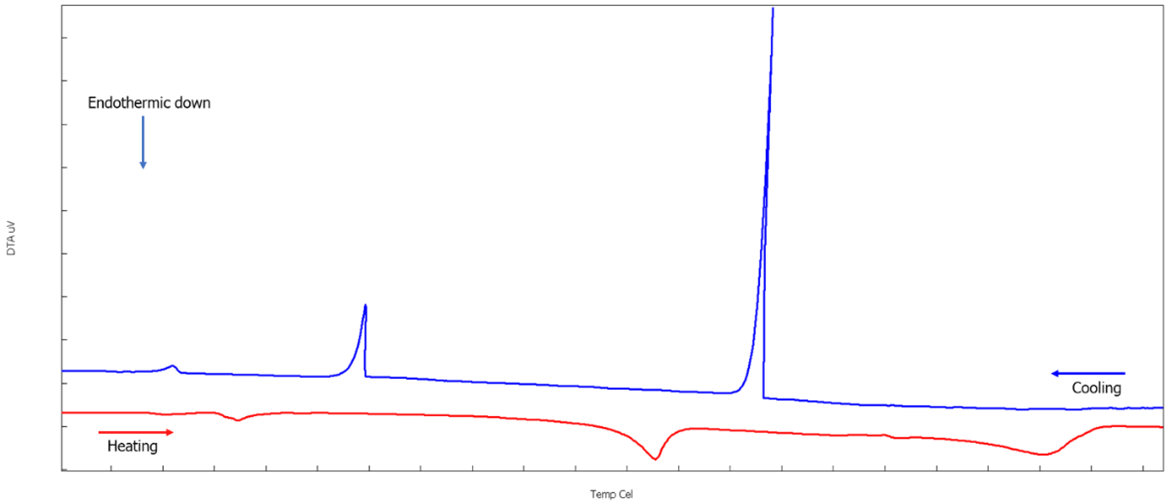

Figure 1 illustrates the DTA results of a molten salt undergoing controlled heating and subsequent cooling. Joshua points out, “The impressive baseline stability of the STA7200 makes my life easier when it comes to data processing.”

Image Credit: Hitachi High-Tech Analytical Science Ltd

Being There When It Matters

When the equipment failed after not being used for many years and needed repair, Hitachi was able to very quickly send out a service engineer who was able to spot the fault within an hour.

The instrument was sent to one of Hitachi’s repair centers to be fixed and was returned to the research lab at Lancaster University within weeks. Hitachi’s service team also made sure that the instrument had the right calibration for Joshua’s work so that it would be able to provide both highly precise and accurate measurements.

When problems arise, which they always do, what impressed me the most was that Hitachi’s team were available and very responsive. This was fantastic as the whole process has completely exceeded our expectations as we thought it would take months. Hitachi also arranged a courier which made everything run much smoother. This was by far the best experience the university has had with an external company with a similar situation.”

Joshua Findley, Postgraduate Researcher, Lancaster University

Hitachi’s service team promptly managed the processing and ordering of any necessary parts or accessories. Joshua was kept well informed through regular updates, including valuable details like lead times and expedient suppliers.

Joshua continued, “Not only has the response time and helpfulness of the Hitachi team impressed me, but Hitachi’s TA experts have also provided insightful advice which have aided the decision choices and steered my project in the right direction. This has saved me both valuable time and money from my total allowable budget. They really didn’t have to do this, to go out of their way to provide me with additional information and tips.”

NEXTA STA Thermal Analyzer – Visibly Better Thermal Analysis

For over fifty years, Hitachi’s range of thermal analyzers has been relied upon for dependable analysis within research and development and quality control settings.

Hitachi’s latest STA analyzers seamlessly integrate DSC, DTA, and TGA technologies. This long-standing, favored choice among research groups and institutions empowers a comprehensive understanding of the materials under study.

The analyzers facilitate heat capacity measurements reaching up to 1500 °C, employing either the conventional three-curve method or modulated DSC.

The newest STA model, the NEXTA STA, builds upon the accomplishments of its predecessors, allowing the detection of even the slightest weight alterations across an expansive temperature spectrum. This capability ensures that the material’s performance and quality adhere to the required standards.

Keeping You Running

Hitachi’s extensive global network of service centers provides a comprehensive spectrum of technical support services, ensuring the uninterrupted operation of its equipment.

From repairs, recertification, and maintenance to comprehensive training aimed at optimizing instrument utilization, Hitachi’s specialized team remains on hand to offer whatever help may be needed. Moreover, Hitachi offers an array of consumables and accessories, assuring that genuine components are employed for the client’s analytical needs.

Supplementary resources, spanning tutorial videos to answers addressing frequently asked questions, are accessible within the service section of Hitachi’s website, enabling clients to develop a profound comprehension of their analyzer.

This information has been sourced, reviewed and adapted from materials provided by Hitachi High-Tech Analytical Science.

For more information on this source, please visit Hitachi High-Tech Analytical Science.