Sponsored by PerkinElmerReviewed by Olivia FrostSep 12 2023

As the global population continues to increase, the corresponding rise in food production will profoundly impact the food industry.

Image Credit: Nanderdewijk/Shutterstock.com

Under the current model, which heavily depends on industrial farming, meeting the growing demand for food will necessitate increased output from industrial farming. This will further contribute to the environmental footprint by generating more greenhouse gases.

There is an urgent need to adopt new strategies to fulfill the rising demand for food production while concurrently mitigating its environmental consequences. Sustainable food sources are undeniably crucial in addressing this global food production crisis.

The primary considerations when choosing new food sources include superior flavor profiles, widespread availability, sustainable procurement, affordability, and optimal nutritional content.

This article will delve into sustainable food sources that align with these criteria and the key analytical innovations required to introduce them to the market.

The Global Food Production Crisis is a matter of great concern. According to the United Nations, the world's population is estimated to reach 9.8 billion by 2050 and 11.2 billion by 2100.1

To feed this anticipated population growth, governments worldwide must proactively increase their food resources to meet the surging demand.

A significant challenge arises when examining the existing food production paradigm. It becomes evident that agriculture, particularly industrial farming, contributes substantially to one of the largest environmental burdens, primarily through the emission of greenhouse gases, notably methane.

Agricultural commodities used for livestock feed demand substantial water resources. As water becomes scarcer in some areas of the world, these feed commodities, if not already, will impose significant environmental strain.

This reliance on livestock as a primary food source drives the expansion of feed commodities, leading to the depletion of large tracts of rainforests and other ecosystems that act as carbon sinks, exacerbating global warming.

Addressing the global food production crisis necessitates an alternative approach distinct from the current food production paradigm.1

The Sustainable Food Solutions

As industrial livestock operations demonstrate negative environmental impacts, the need for establishing sustainable food sources to meet growing food demands becomes increasingly evident. To address this challenge, food manufacturers worldwide are exploring various protein sources that meet the following criteria:

- Environmentally sustainable

- Have optimal nutrient composition

- Cultivated in a socially responsible way

Several promising sustainable food sources have emerged, including insects, cultured meat, fungi, algae, and plants.

Insect Protein Sources

Insect protein sources offer significant protein-to-mass ratios, rendering them ideal choices for alternative protein development. Beyond direct consumption, insects are also considered a source of animal feed.

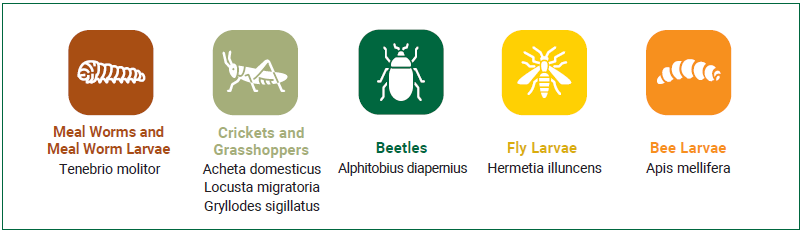

Five of the various insects currently being evaluated for mass protein production stand out as top options.2 Figure 1 illustrates some of these key insect sources.

Insect Processing, Formulation, and Analytical Considerations

To prepare insects for mass distribution, manufacturers must undertake several processing and formulation steps to achieve the desired end product.

The production process involves identifying the key insect species and their relevant developmental stages, analyzing endogenously produced compounds that may raise concerns, and assessing any physical or ecological risks associated with each species' mass production and harvesting.3

After the selected species are determined, insect varieties are farmed following the determination of rearing conditions and feeding optimizations for maximum yields.

Subsequently, insects are separated from frass and decaying animals, harvested, and then euthanized. Processing becomes possible, allowing manufacturers to conduct microbiological assessments, evaluate process contaminants, and determine the stability of end products.3

Figure 1. Top inspect protein sources. Image Credit: PerkinElmer

Insect Safety Considerations

Preparing insect food products requires a detailed qualitative and quantitative characterization of the main components within the insect tissue matrix. Rigorous safety assessments must be applied throughout the entire processing lifecycle to ensure the removal of allergens and unwanted materials, such as chitin, from the final product.4

Nutritional information must also be characterized and quantified, including protein quantification, protein quality, starch analysis, lipid analysis, fiber analysis, macronutrient analysis, and anti-nutritional factors.

Additional considerations involve vitamins, minerals, the impact of feed on bioaccumulation and cross-contamination, stability, and processing contaminants.4

Cultured Meat

Food products derived from cultured cells provide a sustainable food source in their development while offering nutritional profiles, textures, and tastes similar to traditional animal-derived food products.

Cultured meat is produced by isolating stem cells from livestock animals and placing them in a growth medium. This results in the formation of myotubules, ultimately forming muscle tissue, enabling developers to recreate the tastes and textures of traditional meat products.5

Key elements of characterization that must be considered with cultured meat products include:

- Identification of impurities, by-products, and antimicrobial/ mycotoxin residues

- Nutritional profiles

- Safety profiling of various biohazards, including viruses, contaminants, and BSE/TSE

- Comprehensive analysis targeting analytes, which will vary based on stem cell source and production process

Cultured Meat Processing, Formulation, and Analytical Considerations

The cultured meat production process involves cell treatment, modification, and immortalizing of stem cells. Therefore, added consideration must be given to the raw materials and starting substances used in production.

Key considerations include the growth medium, substrate, growth factors and hormones, antimicrobials, culturing parameters, and analytical equipment employed.5

Cultured Meat Safety Considerations

Comprehensive safety testing using analytical instrumentation is essential to determine impurities, microbiological toxins, and allergens.

In addition to compositional data obtained from analytical testing, bioinformatic data analysis is valuable for examining genetic and proteomic aspects in greater detail. Key 'omics' of interest in cultured meat safety and production include genomics, proteomics, metabolomics, and transcriptomics.5

Plant-Based Foods

Plant-based foods are widely recognized as a leading sustainable food source worldwide due to their well-established global manufacturing infrastructure and sustainable production potential.6

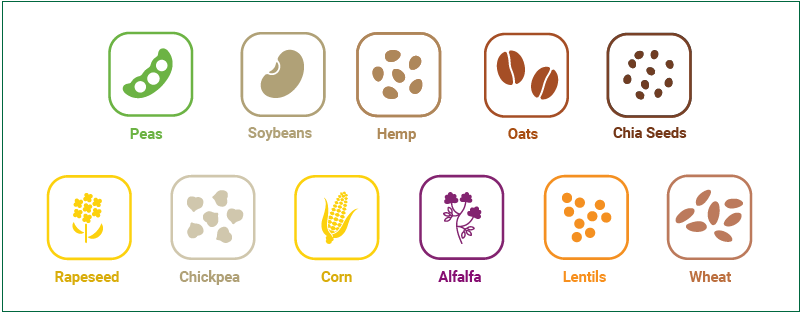

Figure 2 illustrates some of the key plant sources utilized for mass production. Each plant source differs significantly in protein, carbohydrate, starch, nutrient, and anti-nutrient profiles. Therefore, comprehensive analyses are required to determine the compositional profiles of various plant varieties.

Further analysis is necessary to assess protein digestibility and nutrient bioavailability.6

Figure 2. Key plant sources. Image Credit: PerkinElmer

Plant Processing, Formulation, and Analytical Considerations

Plant food sources require processing in various forms, such as whole plants, grains, seeds, leaves, and roots. Processing yields protein-based powders, protein isolates/concentrations, and other products, including fermented protein mixtures.

Achieving textures, tastes, and scents matching traditional meat sources is critical for adopting plant-based foods.

Some plant proteins have stronger flavors than others, complicating the formulation requirements needed to bring competitive products to market. Therefore, comprehensive formulation analysis is necessary to develop market-ready products.6

Plant-Based Food Safety Considerations

Plant-based foods contain various microbial, chemical, and antinutritional compounds that require assessment before market release.7

Key safety analyses include:

- Contaminant testing (includes analysis of primary and secondary metabolites, process enzymes, heavy metals, and residues of cultivation conditions)

- Microbiological testing (includes analysis of microbial counts and relevant toxins)

- Process contaminants (includes thermal processing, maillard reaction products, and acrylamide)

- Macro and micronutrients

- Antinutritional factors

- Allergens

Algae

It is estimated that single cells, like algae, could potentially satisfy up to 20% of the demand for conventional crop-based animal feed protein by 2050. Some species of algae, such as spirulina, contain nearly 70% protein, making them an efficient starting point for the development of alternative protein sources.

Algae exhibit rapid growth and do not rely on land use, rendering them an ideal environmentally-friendly food source. There are more than 300,000 known algae species, with several currently under consideration for food development, including:

- Arthrospira platensis

- Fusiformis

- Maxima

- Laminaria digitata

- Galdieria sulphuraria

- Schizochytrium sp.

- Phaeodactylum tricornutum

- Tetrraselmis chuii

Algae Processing, Formulation, and Analytical Considerations

Once a species is selected, the production process begins by developing fermentation and cultivation conditions, such as temperature, time, pH, light quantities, and open or closed systems. Concentration parameters must be assessed, along with procedures for detecting cell viability.8,9

Algae Safety Considerations

Before proceeding with development and formulation steps, the following safety considerations must be examined:9

- Nutritional composition

- Algae toxins and heavy metal analysis

- Particle size distributions

- Stability testing

- Allergen testing

Fungi

Fungi have served as food sources since 16,700 BC, with the earliest evidence of human consumption found in Boletales Mushrooms. The versatility, diversity, nutritional profiles, texture, flavor potential, and environmental sustainability of fungi make them ideal candidates for sustainable food development.

As nature's decomposers, fungi are considered excellent options for circular and precision manufacturing applications, opening up many new opportunities for fungal biomass production.10

Fungal Processing, Formulation, and Analytical Considerations

To optimize fungal manufacturing and facilitate future development, it is essential to determine the ideal growth conditions for various agricultural and food products, including almond hulls.

This process involves analyzing key parameters such as sugar consumption, macronutrient, and micronutrient profiles. Formulating fungal products into commercially distributed end products will require further analytical support.10

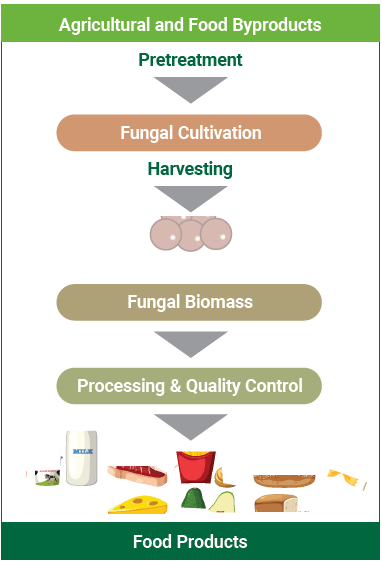

Figure 3 illustrates the basic processing workflow of fungal cultivation to the end-product formulation.

Fungal Safety Considerations

Before advancing with development and formulation steps, it is imperative to analyze the following safety parameters:10

- Nutritional composition

- Mycotoxins and heavy metals

- Pesticides

- Stability

- Allergens

Figure 3. Basic processing workflow of fungal cultivation to end-product formulation. Image Credit: PerkinElmer

Key Analytical Technologies for Sustainable Food Analysis

Employing the appropriate analytical technology can provide valuable insights into various critical developmental parameters. Analytical analysis establishes operational limits and essential production process parameters, ensuring quality.

Companies that harness emerging innovations in analytical technology are poised to secure a position in this evolving food landscape. Table 1 provides an overview of analytical technologies for key food testing instrumentation.11

Key Analytical Technologies

NIR (Near Infrared) Analyzers

PerkinElmer's NIR at-line or in-process analyzers offer by-product analysis and ensure consistency throughout the production process. They verify ingredients and finished product quality while enabling real-time monitoring of key nutritional parameters like fat, moisture, protein, collagen, and salt.

The utilization of NIR instrumentation obtains results within seconds, significantly enhancing production monitoring and optimization.12

Processes and at-line NIR analyzers, such as the DA 7350™, DA 7440™, and DA 7250™, demonstrate their worth in optimizing alternative protein processing. They maximize profitability through increased yield, reduced waste, and improved raw material usage.

Typically, in-line and on-line NIR instruments manage processes such as drying, stream blending, ingredient additions, fraction segregation, and product quality monitoring.

Table 1. Analytical technology overview of key food testing instrumentation11. Source: PerkinElmer

| What to test? |

How to test? |

| Quality Standards |

Chemical analysis, gravimetric, titrimetric, chromatography |

| Metal Contaminants |

Chemical, AA, ICP-OES, ICP-MS |

| Pesticides |

GC, GC/MS, LC/MS/MS, HPLC |

| Veterinary Drugs |

HPLC, LC/MS/MS |

| Additives |

Chemical, HPLC, GC, GC/MS, LC/MS/MS |

| Nutritional Parameters |

Chemical, HPLC, GC, ELISA, LC/MS/MS, AA, ICP-MS |

| Microbiology |

Conventional, ELISA, PCR |

| Adulterants |

Chemical, GC, HPLC, TLC, LC/MS/MS |

| Allergens/Mycotoxins |

ELISA, HPLC, LC/MS |

| Flavors |

GC, GC/MS |

| Food Packaging |

FT-IR, GC/MS, GC-HS |

| Food Labeling |

CHNO, GC, GC/MS, HPLC, LC/MS, AA, ICP-OES |

| Quality Analysis |

NIR, FT-NIR |

| Out of Lab Solution |

Portable GC/MS, FT-NIR |

Key Distinguishing Factors Between PerkinElmer’s Process NIR Analyzers

The DA 7350™ assesses parameters in direct contact with the product and is specifically designed for bulk products, pastes, and slurries within a processing line. The DA 7350™ incorporates a built-in camera for flow visualization and color measurements, particularly beneficial in grain, flour, and feed processing.

Applications for the DA 7350™ include optimizing protein content in wheat stream blending before milling, ash content in flour production, and grain yield optimization by controlling gluten and starch separation during milling.

The DA 7440™ is an on-line NIR instrument measuring products on a conveyor belt or similar transportation system, offering real-time measurement for automatic or manual process control.

Examples of DA 7440™ applications encompass controlling flavoring-salt addition to plant-based foods to reduce ingredient costs, optimizing milling settings to increase yield, and scanning plant-based products to monitor moisture, protein, and fat content.

NIR instrumentation has demonstrated its efficacy in meat analysis, making it suitable for both cultured and traditional animal meat applications.

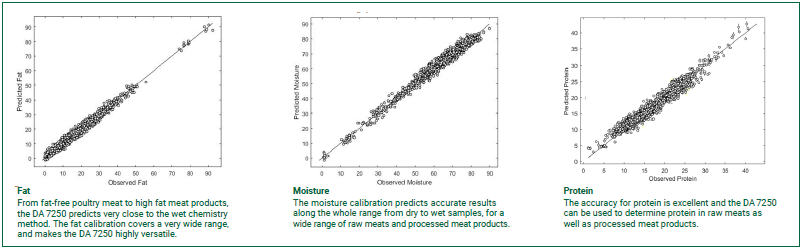

As showcased in this article, 5,000 meat samples comprising raw and processed beef, poultry, and pork products were successfully analyzed. These samples were homogenized and analyzed on multiple DA 7250™ instruments employing open-faced dishes.

Various regression techniques were evaluated for calibration development, including ANN and PerkinElmer's proprietary Honig's Regression™, designed for handling extensive datasets with diverse product variability.12

It was concluded that Honig's Regression delivered the best performance, allowing the amalgamation of various sample types into a unified global calibration without compromising performance.

The DA 7250™ achieved reproducibility results akin to the respective reference method, delivering accurate analysis of multiple parameters within seconds using a single calibration for all sample types. Refer to Figure 4 for a depiction of the reproducibility and accuracy achieved by the DA 7250™ employing Honig's Regression.12

FTIR Spectroscopy

Alternative protein formulation solutions will undoubtedly rely on utilizing FTIR spectroscopy, such as PerkinElmer's FT 9700™ FT-NIR analyzer to rapidly determine amino acids.

Another crucial application of FTIR will involve quantifying and ensuring removing unwanted and challenging-to-digest proteinaceous material, such as insect chitin, from the end product material.

Figure 4. The DA 7250 NIR Analyzer results, using the Honig’s Regression, from over 5,000 meat samples taken from a variety of beef, pork and poultry products.12 Image Credit: PerkinElmer

Performance Analyzers

Performance analyzers are vital for ingredient analysis. Instruments like PerkinElmer's Rapid Visco™ Analyser (RVA) are ideal for evaluating textural changes, ensuring efficient product development, process control, and quality assurance.

Sustainable food product developers and manufacturers target specific performance characteristics, which can pose challenges. Sustainable food ingredients' performance is affected by their extraction and processing conditions, such as shear, pH, filtration technique, and extraction reagents.

PerkinElmer's RVA finds widespread use in the food industry. It describes ingredient performance and quantifies processing effects, measuring hydration, shear thinning, cooking, and gelling performance.

This simplifies and expedites the reformulation process in the alternative proteins industry, establishing quality control parameters for incoming ingredients and evaluating new ingredient performance. Measuring ingredient performance enhances product quality and consistency while reducing time-to-market for new products.

UHPLC/MS/MS and LC/MS/MS

Chromatography systems coupled to tandem MS/MS configurations provide ultra-sensitive detection capabilities ideally suited for mycotoxin, pesticide, and other contaminating compounds.

These systems will significantly benefit all five alternative protein sources, as impurity analysis will be crucial for commercial development.13

The advantages of multiclass-multianalyte method development for mycotoxins in foods are demonstrated in the article "Mycotoxins in Food" by IAC.

Using PerkinElmer's QSight® LC/MS/MS systems, researchers have developed and validated a robust method for the reliable confirmation and quantification of twelve mycotoxins in various food matrices.

All the analyzed mycotoxins, with diverse physicochemical properties, can be determined simultaneously in a single chromatographic run within 11 minutes.

Tables 2 and 3 present the results of the validated method in eight different food matrices (maize, wheat, soybean, oat cereal, almond, peanut butter, red chili, and black pepper) with good sensitivity, selectivity, accuracy, and precision for all the analyte/matrix combinations.13

GC and GC/MS

Gas Chromatography (GC) proves highly valuable as an analytical tool for identifying pesticides, additives, nutritional content, adulterants, food labeling, packaging, and flavor analysis.

The GC 2400™ System, discussed in this article, is an excellent analytical instrument for assessing the fatty acids isolated from edible oils in food products. This assessment aids in determining both the quality of sustainable food products and the detection of potential adulterations.14

ICP-MS and ICP-OES

Inductively coupled plasma mass spectrometry (ICP-MS) and inductively coupled plasma optical emission spectroscopy (CP-OES) play a pivotal role in alternative protein development, primarily in determining elemental and mineral compositions, crucial for nutritional and toxic element profiling.

Hence, it is of utmost importance that the instrumentation possesses ultra-trace detection capabilities to identify trace contaminants and nutritional elements.

PerkinElmer’s NexION® ICP-MS series has consistently provided accurate and validated data, as demonstrated in several articles. These applications have successfully addressed conventional challenges in elemental analysis, including complex sample matrices, high levels of dissolved solids, and interferences in protein samples.15

In a specific article focused on analyzing major and trace elements in plant-based foods, researchers showcased the ability of PerkinElmer’s NexION® 2000 ICP-MS to effectively measure both major and trace elements in a single analytical run.15

Atomic Absorption (AA)

Atomic Absorption (AA) through flame atomic absorption instrumentation offers an alternative approach for analyzing micronutrients and minerals.

While ICP-OES typically enjoys preference in a multi-element analytical context, the cost-efficiency, simplicity, and speed of operation of a flame atomic absorption (AA) system make it a favorable alternative solution, depending on the laboratory's requirements.

Analyzing multiple elements via flame AA entails individual sample analysis for each element, extending the analysis time for flame AA applications. To address this, a high-throughput sample automation system can be employed to ensure robust analysis of sustainable food ingredients.16

Table 2. Mycotoxin recovery from food samples at spiking level one. Source: PerkinElmer

| Analyte |

Spiked |

Method Accuracy or Analyte Recovery from Sample Matrix (%) |

| |

(μg/kg) |

Corn |

Wheat |

Soybean |

Oat Cereal |

Almond |

Peanut Butter |

Black Pepper |

Chili Powder |

| Aflatoxin B1 |

1 |

94,5 |

112 |

91,1 |

102 |

101 |

91 |

120 |

102 |

| Aflatoxin B2 |

1 |

85,5 |

105 |

86,9 |

86,8 |

89,1 |

89,6 |

102 |

107 |

| Aflatoxin G1 |

1 |

96,2 |

103 |

90,4 |

97,9 |

101 |

104 |

101 |

99,3 |

| Aflatoxin G2 |

1 |

89,9 |

105 |

88,5 |

86 |

88,5 |

96,7 |

95,6 |

98,2 |

| Ochratoxin A |

2 |

95 |

95,4 |

91,4 |

88,9 |

100 |

105 |

97,5 |

96,1 |

| Fumonisin B1 |

100 |

103 |

95,5 |

109 |

95,2 |

95,2 |

98,6 |

101 |

104 |

| Fumonisin B2 |

100 |

104 |

112 |

103 |

100 |

96,5 |

96,8 |

94,2 |

105 |

| Fumonisin B3 |

100 |

101 |

114 |

110 |

95 |

95,1 |

104 |

97,9 |

105 |

| Deoxynivalenol |

100 |

101 |

76,6 |

103 |

94 |

115 |

97,7 |

97,4 |

95,8 |

| Zearalenone |

30 |

110 |

92,2 |

94 |

102 |

112 |

105 |

85,1 |

105 |

| HT-2 Toxin |

100 |

86,9 |

86,1 |

82,7 |

103 |

92,4 |

104 |

99,9 |

102 |

| T-2 Toxin |

10 |

92,3 |

100 |

99,9 |

94,1 |

105 |

103 |

104 |

111 |

Table 3. Mycotoxin recovery from food samples at spinking level two. Source: PerkinElmer

| Analyte |

Spiked |

Method Accuracy or Analyte Recovery from Sample Matrix (%) |

| |

(μg/kg) |

Corn |

Wheat |

Soybean |

Oat Cereal |

Almond |

Peanut Butter |

Black Pepper |

Chili Powder |

| Aflatoxin B1 |

5 |

98 |

88,2 |

97,3 |

97,7 |

114 |

93 |

103 |

103 |

| Aflatoxin B2 |

5 |

93,3 |

86,8 |

95,6 |

87,3 |

112 |

105 |

107 |

103 |

| Aflatoxin G1 |

5 |

104 |

88,3 |

104 |

98,3 |

117 |

103 |

98,7 |

102 |

| Aflatoxin G2 |

5 |

91,2 |

87,7 |

97,2 |

93,4 |

110 |

109 |

103 |

105 |

| Ochratoxin A |

10 |

97,6 |

90,9 |

95,2 |

90,4 |

116 |

101 |

83,2 |

96,3 |

| Fumonisin B1 |

250 |

90,6 |

108 |

109 |

95 |

129 |

97,6 |

97,4 |

94,7 |

| Fumonisin B2 |

250 |

107 |

115 |

113 |

100 |

123 |

104 |

104 |

106 |

| Fumonisin B3 |

250 |

98 |

115 |

118 |

99,6 |

126 |

102 |

103 |

100 |

| Deoxynivalenol |

250 |

98,5 |

95,9 |

101 |

95,7 |

113 |

97,7 |

99,9 |

96 |

| Zearalenone |

75 |

101 |

99 |

99,8 |

112 |

117 |

108 |

95,2 |

111 |

| HT-2 Toxin |

250 |

85,4 |

92,3 |

91,5 |

96,7 |

102 |

102 |

101 |

99,1 |

| T-2 Toxin |

25 |

90,4 |

110 |

107 |

104 |

115 |

105 |

104 |

106 |

The Future of Alternative Proteins

The future of sustainable foods necessitates improvements in yield and post-optimization production in both R&D and analytical research. A recent R&D breakthrough illustrates this by merging fungal species development with microalgae cultivation.

Researchers have devised an optimized approach that employs fungal mycelium as a living scaffold for attaching and proliferating microalgae cells. This co-culturing method has the potential to significantly enhance the production of both fungal and algae biomass, surpassing what would be achievable if conducted independently.

Analytical technology continually evolves, driving product development and production optimization enhancements by utilizing increasingly versatile, rapid, and sensitive equipment.

While the global food crisis presents challenges for the future, it also creates substantial opportunities within the food industry. Companies that capitalize on emerging innovations in analytical technology are poised to secure a prominent position in this evolving landscape of alternative food production.

References and Further Reading

- Nations, United. “World Population Projected to Reach 9.8 Billion in 2050, and 11.2 Billion in 2100.” United Nations, 2017, https://www.un.org/en/desa/world-population-projected-reach-98-billion-2050-and-112-billion-2100

- Tyler A Churchward-Venne, Philippe J M Pinckaers, Joop J A van Loon, Luc J C van Loon, Consideration of insects as a source of dietary protein for human consumption, Nutrition Reviews, Volume 75, Issue 12, December 2017, Pages 1035– 1045, https://bygora.com/2021/04/insect-protein-production/

- “Insect Protein Production | Bygora.com.” Bygora.com, 20 Apr. 2021, https://bygora.com/

- Hadi J, Brightwell G. Safety of Alternative Proteins: Technological, Environmental and Regulatory Aspects of Cultured Meat, Plant-Based Meat, Insect Protein and SingleCell Protein. Foods. 2021 May 28;10(6):1226. doi: 10.3390/ foods10061226. PMID: 34071292; PMCID: PMC8230205.

- Hong TK, Shin DM, Choi J, Do JT, Han SG. Current Issues and Technical Advances in Cultured Meat Production: A Review. Food Sci Anim Resour. 2021 May;41(3):355-372. doi: 10.5851/ kosfa.2021.e14. Epub 2021 May 1. PMID: 34017947; PMCID: PMC8112310.

- Fischer R, Schillberg S, Buyel JF, Twyman RM. Commercial aspects of pharmaceutical protein production in plants. Curr Pharm Des. 2013;19(31):5471-7. doi: 10.2174/1381612811319310002. PMID: 23394566.

- Krajcovicova-Kudlackova M, Babinska K, Valachovicova M. Health benefits and risks of plant proteins. Bratisl Lek Listy. 2005;106(6-7):231-4. PMID: 16201743.

- Algae as an Alternative Protein | Nutrition | Bühler Group. https://www.buhlergroup.com/global/fr/key-topics/Nutrition/Algae.html

- Bleakley S, Hayes M. Algal Proteins: Extraction, Application, and Challenges Concerning Production. Foods. 2017 Apr 26;6(5):33. doi: 10.3390/foods6050033. PMID: 28445408; MCID: PMC5447909.

- Tyler J. Barzee, Lin Cao, Zhongli Pan, Ruihong Zhang, Fungi for future foods, Journal of Future Foods, Volume 1, Issue 1, 2021, Pages 25-37, ISSN 2772-5669, https://www.sciencedirect.com/journal/journal-of-future-foods/vol/1/issue/1

- Food Testing Solutions Overview Guide SOLUTIONS for FOOD SAFETY. PerkinElmer. https://resources.perkinelmer.com/lab-solutions/resources/docs/BRO_014099_01_GDE_Food_FINAL.pdf?_ga=2.234583065.649947376.1675279276-959910894.1636649348

- Analysis of Meat and Meat Products using the DA 7250 NIR Analyzer. Application Note. PerkinElmer. https://www.perkinelmer.com/libraries/APP_DA-7250_Meat-meatproducts

- Multiclass-Multianalyte Method for Mycotoxin Testing in Foods Using Immunoaffinity Column Sample Clean-up with QSight LC/MS/MS. Application Note. PerkinElmer. https:// www.perkinelmer.com/libraries/APP-145410-Mycotoxins-inFood-by-IAC-LCMSMS

- GC-FID Fast and Accurate Analysis of Fatty Acid Methyl Esters (FAMEs) In Edible Oils and Food Products for the Determination of Product Quality and Authenticity. Application Note. PerkinElmer. 2023. https://www.perkinelmer.com.cn/libraries/app-FAME-GC-FID-gc-2400-platform

- Analysis of Major and Trace Elements in Plant-Based Foods Using the NexION ICP-MS. PerkinElmer, 2023 https://www.perkinelmer.com.br/libraries/app-nexion-2000-icp-ms-major-trace-elements-in-plant-based-foods

- Micronutrients in Fortified Breakfast Cereal by Flame AA Using Microwave Digestion and FAST Flame Automation| PerkinElmer, 2023. https://www.perkinelmer.com/uk/libraries/app_fast-flame-pinaacle-900-cereal-micronutrients-012240_01

This information has been sourced, reviewed and adapted from materials provided by PerkinElmer.

For more information on this source, please visit PerkinElmer.