3D printing, also known as additive manufacturing (AM,) has evolved in leaps and bounds in recent decades to become an exciting emerging manufacturing technology in multiple industries. This article will explore metal printing, which is revolutionizing the landscape of additive manufacturing.

Image Credit: asharkyu/Shutterstock.com

3D printing is a relatively recent technology that is changing the face of manufacturing. Using 3D printing processes, designers are able to create parts from different materials such as polymers, ceramics, and metals.

Aside from this multimaterial printing capacity, 3D printing has significant benefits for companies and hobbyists, including freeform design capabilities and a distinct lack of wasted materials compared to traditional subtractive manufacturing processes. Aerospace, the automotive sector, and clinical science are some of the areas which utilize this technology.

There are many different types of 3D printing technology available to the industry, including inkjet printing, fused deposition modeling, stereolithography, digital light processing, electron beam melting, multi-jet fusion, and selective laser sintering.

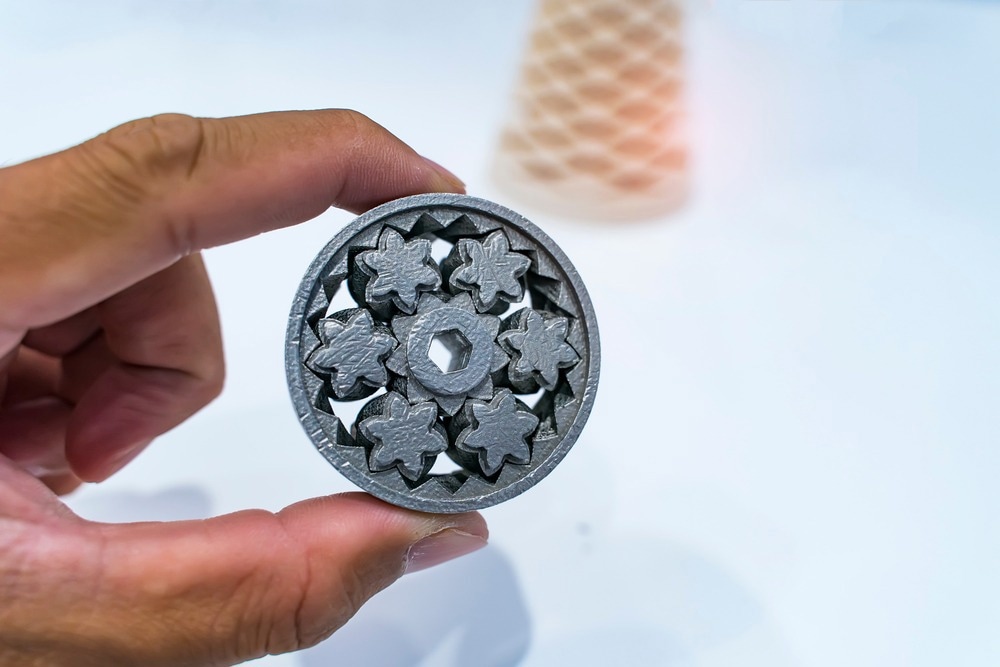

The technology is nearly synonymous with rapid prototyping and is able to fabricate parts with complex, replicable internal geometries. Each method has its own advantages, which make it suitable for different materials and industries.

What is Metal 3D Printing?

3D printing metal parts has emerged as a viable undertaking in manufacturing due to recent advances in a number of related additive manufacturing technologies. The ability to rapidly prototype and replicate complex metal parts with minimum waste provides significant opportunities for sectors such as the automotive industry.

Metals are typically prepared as powders before they are used to produce printed parts. Some methods extrude heated metal rods according to a pre-programmed geometry to build a part one layer at a time.

3D Metal Printing Technologies

3D metal printing has evolved in leaps and bounds in recent years, opening up many opportunities for producing parts from multiple kinds of metallic materials. Some of the common 3D metal printing methods are listed below.

Direct Metal Laser Sintering (DMLS)

DMLS is one of the most commonly utilized additive manufacturing processes for producing metal parts. Powdered metal beds are subjected to powerful CO2 lasers which trace the geometry of the final part. This technology can be used for multiple materials and was one of the earliest 3D methods developed.

Parts are printed layer by layer, with the powder bed moving down as each layer is produced. These layers are bonded together in the process, and printing continues until the complete part is produced.

Selective Laser Melting (SLM)

Also similar to DMLS, in SLM the powder bed particles are melted rather than sintered. Due to the high heat required, SLM is an extremely energy-intensive process and can cause internal stresses in the final product. However, SLM produces stronger and denser parts than DMLS.

SLM can be used to print parts from materials such as cobalt chrome, nickel alloys, tool steel, stainless steel, and titanium.

Electron Beam Melting (EBM)

Similar to SLM, EBM uses a different heat source. As the name suggests, this process utilizes an electron beam rather than a laser. However, EBM can only be used for a limited range of materials.

Directed Energy Deposition (DED)

DEPD uses powdered metal or wires as a feedstock material to produce parts. Different types of beams are used to melt the material under an inert atmosphere.

Multiple variants of DED exist, including Laser Engineered Net Shaping, Rapid Plasma Deposition, and Wire Arc Additive Manufacturing. These, respectively, use lasers, plasma arcs, and electric arcs.

Ultrasonic Additive Manufacturing (UAM)

UAM is a novel and innovative 3D metal printing method that uses ultrasonic energy to produce parts. Using this process, products retain both density and strength as no melting is involved, and UAM can be used on feedstock materials such as stainless steel, copper, titanium, and aluminum.

MELD

MELD is an innovative additive manufacturing process that involves no melting or sintering, making it a highly versatile method for 3D metal printing. Aside from parts manufacturing, MELD can be used for post-fabrication applications, repairs, and joining.

The crucial difference between MELD and other metal additive manufacturing methods lies in how it forms parts. High force and friction are used to melt the feedstock until it flows freely, behaving like a viscous liquid. However, it is a highly plasticized solid material.

MELD is a one-step solid-state manufacturing process that can produce parts with superior performance characteristics similar to, or even better than, parts produced using conventional subtractive methods such as machining.

Cold Spray Additive Manufacturing

Another unique 3D metal AM method, cold spray additive manufacturing, uses no heat, sintering, or melting to produce printed products. Instead, metal powder is fired at a substrate layer by a supersonic gas jet. The high velocity causes layers and material to fuse together, plasticizing on impact.

A robot is used to precisely control the material jet and build complex parts. One of the main advantages of cold spray additive manufacturing is its speed, which outperforms more conventional 3D printing processes.

In Summary

3D metal printing is an emerging field of additive manufacturing that is highly useful for a number of industries, including the automotive, aerospace, and biomedical sectors. Several processes have been developed in recent decades which allow the construction of high-performance parts with complex architectures.

As more companies leverage the environmental and financial benefits of 3D metal printing methods, these technologies will doubtlessly continue to grow in popularity, creating new parts with the minimum of waste and energy consumption.

The Global 3D Printing Market - Growth, Trends, and Applications

References and Further Reading

Manufacur3d (2021) A Comprehensive List of Metal 3D Printing Technologies (2023) [online] manufactur3dmag.com. Available at:

https://manufactur3dmag.com/a-comprehensive-list-of-metal-3d-printing-technologies

Ahart, M (2019) Type of 3D Printing Technology [online] protolabs.com. Available at:

https://www.protolabs.com/resources/blog/types-of-3d-printing/

Cherdo, L (2022) Metal 3D printers in 2023: a comprehensive guide [online] aniwaa.com. Available at:

https://www.aniwaa.com/buyers-guide/3d-printers/best-metal-3d-printer/

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.