Taking steps to automate a lab can deliver more repeatable test results and higher throughput.

Plastics laboratories often face the task of examining a substantial number of comparable samples while striving to maintain consistent and dependable outcomes.

While some may manage this challenge through predominantly manual, human-operated procedures, most companies stand to gain significant advantages by introducing automation to at least some of their testing equipment.

The integration of automation into existing testing procedures can offer several benefits to plastics manufacturers, including:

- More repeatable results

- Higher throughput

- Better (and safer) use of labor

- More secure test data

The degree of these advantages may differ among manufacturers, but most laboratories can anticipate experiencing a substantial return on investment (ROI) by taking steps toward automation.

Enhanced Repeatability

Maintaining consistency in results poses a significant and formidable challenge for plastics laboratories handling hundreds of similar samples daily.

Adhering to stringent testing standards like ASTM D638 or ISO 527 necessitates uniform results, which can be elusive when human error is a potential factor.

Many plastics standards are complicated and require "very, very precise" measurements such as modulus, said Instron applications engineer Sammi Sadler.

Variations in technique among different operators or even within the actions of a single operator can lead to less reliable and consistent test data. For instance, a human operator may occasionally struggle to load a sample perfectly vertically, and such discrepancies in alignment can impact the results significantly.

According to Sadler, the primary sources of variation in plastics testing typically arise from alignment, measurement, and grip pressure.

If we're thinking about screw side action grips to test plastics, the amount of pressure that they apply when clamping onto the specimen — that pressure could vary from specimen to specimen, or from user to user.

Sammi Sadler, Applications Engineer, Instron

Instron AT3 Automates Tensile/Flex Testing to ASTM D638, D790 & ISO 527, 178 (+ Video Extensometry)

Video Credit: Instron - USA

An automated setup addresses this challenge by ensuring every sample is uniformly measured, inserted, and aligned. This approach holds substantial potential for saving time and resources, which would otherwise be expended on discarding failed samples.

With access to more consistent data that remains unaffected by human errors or discrepancies, laboratory operators can conduct result analysis with greater ease, as highlighted by Kelvin Fernandez, Instron's upstream marketing manager for robotics systems.

"You can say, 'I know I've cut this variable out, and my results are still bad' — so it's product related, or maybe test setup related or something like that," said Fernandez.

Better Throughput — Without Adding Staff

Given the substantial volume of similar samples encountered in plastics laboratories, introducing automation to specific processes can significantly enhance efficiency and throughput, as stated by Instron automation specialist Richard Spiegel.

Automated testing on an AT3 system. Image Credit: Instron - USA

"It's the same over and over again," he said. "Automation just becomes that much easier, and when it's easier, it becomes that much cheaper."

When a system can autonomously load sufficient samples to run tests overnight without human intervention, the laboratory can augment its throughput without hiring additional staff. The resulting cost savings can help offset the initial investment required for implementing automation.

Optimized Labor

Increased automation levels translate to a human operator's capacity to oversee a wider array of tasks without the need for constant vigilance over the testing apparatus.

As the automated sequence progresses, individuals can analyze data or prepare subsequent sets of samples. In cases where specific test types still necessitate manual intervention, these tests can be executed using a separate system.

Some companies look to embrace automation primarily due to a scarcity of qualified candidates available to fill vacant positions within their laboratory, as noted by Spiegel.

"They don't have someone there to load the test frame anymore," he said. "They're trying to fill a position like that and they're struggling, so they really need to make much better use of the labor that they do have."

Sadler agreed that turnover among testing laboratory personnel contributes to the inclination toward automation.

"It's really frustrating to bring people up to speed on how to test to meet these standards," she said, "so being able to not worry about turnover also adds to the benefit of automation."

Health and Safety

For those human operators engaged in plastic laboratory operations, an automated testing system such as the AT3 or AT6 offers respite from the repetitive tasks of loading and unloading specimens, averting the risk of finger injuries or physical strain stemming from awkward test frame positions.

Rather than performing numerous repetitive motions throughout the day, as Spiegel points out, operators can achieve similar testing volumes with significantly reduced physical exertion. Automated processes handle specimen alignment, measurement, and disposal seamlessly.

"They're now loading a rack into an automation system and hitting Start once," he said. "And it's doing that same amount."

Locked-Down Data

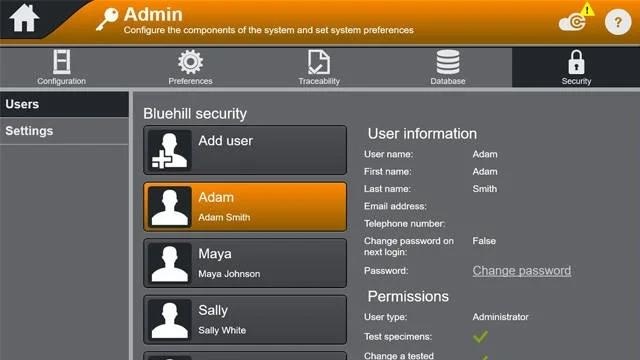

Protecting the testing data is as imperative as the testing procedure itself. Bluehill Universal's test outcomes are automatically transferred to the organization's production system.

By enabling the appropriate security features within the software, individuals lacking the requisite training and experience can be assigned lower-level permissions. This precautionary measure helps avert unintentional alterations or deletions of valuable data, ensuring repeatability, a significant challenge in plastics testing.

Bluehill Security helps lab managers set specific permissions for different users, depending on each operator's level of experience. Image Credit: Instron - USA

Bluehill's Traceability Module offers a comprehensive revision history, recording each addition, deletion, or modification, complete with timestamps and the user's name responsible for the changes. Authorized personnel can readily discern what was altered when it occurred, and the person behind the alteration.

You have a very auditable trail of any changes that have been made.

Richard Spiegel, Automation Specialist, Instron

Bluehill provides preconfigured test methods tailored to common plastics testing standards, including ASTM D638, ASTM D790, ISO 527, and ISO 178. This prebuilt functionality considerably streamlines laboratory procedures, reducing the need for manual intervention.

"So they just don't have to think about it," said Sadler. "That's something that also brings comfort to the customer."

Steps Toward Greater Efficiency

Pneumatic grips. Image Credit: Instron - USA

Not every manufacturer in the plastics industry is prepared to embrace a fully automated testing setup. However, even incremental steps can yield significant efficiency improvements.

For instance, upgrading to an automatic extensometer or replacing outdated manual grips can result in more consistent tests for organizations that wish to maintain a human-centric environment.

Going from advanced screw side action grips to pneumatic grips is a huge step toward more repeatable results. And then adding more and more automated solutions is the most ideal.

Sammi Sadler, Applications Engineer, Instron

Depending on the level of automation embraced, a laboratory can witness a profound transformation in its operations. This transformation can lead to increased throughput without the need for additional shifts, allowing human operators to make more productive use of their time.

"Just imagine yourself for eight hours a day, sitting in front of a frame and loading, waiting for it to be done, and then removing the pieces and then reloading again," said Fernandez. "That's the main problem or the main pain point for the customer, really, is that waiting."

This information has been sourced, reviewed and adapted from materials provided by Instron - USA.

For more information on this source, please visit Instron - USA.