The exceptional attributes of technical ceramics, such as excellent material hardness, resilience towards high temperatures, superior tensile attributes, and low toxicity, have made them a popular choice for industrial utilization. In this article, we shall dive into the latest developments in the field of technical ceramics with a focus on the current global market and the future perspective.

A Brief Overview of Technical Ceramics

Technical ceramics, often called advanced or engineered ceramics, consist of inorganic materials that are manufactured from synthetic raw ingredients through a precise manufacturing process to achieve homogeneity and enhance their physicochemical attributes.

Advanced technical ceramics possess unique qualities that guarantee exceptional performance, proving them to be economically viable substitutes for traditional materials such as glass, plastics, metals, and others. The utilization of advanced ceramics is geared towards optimizing efficiency while simultaneously reducing costs, catering precisely to the specific requirements of distinct applications.

Applications of Technical Ceramics

Technical ceramics are utilized in various industries, including aerospace, biomedical, manufacturing, energy storage, etc.

An article published in the Journal of Advanced Ceramics refers to various industrial applications of Silicon-based polymer-derived ceramics, particularly in the energy conversion domain.

The article focuses on the applications of advanced technical polymer-derived ceramics (PDCs). These advanced ceramics are being utilized in the manufacturing of thermal barrier coatings (TBCs). Compared with traditional methods such as the thermal spraying method, the usage of the PDC route leads to distinct advantages such as lower processing temperatures, reduced cost, and higher efficiencies.

A PDC-based dense environmental barrier coating system based on SiNO has recently been developed. Even after being subjected to cyclic oxidation testing at a high temperature of 700℃, the PDC coating was crack-free.

Piezo-resistivity, which is the change in electrical resistivity under stress, presents a fascinating functional application of advanced ceramics. Recent research has revealed that amorphous monolithic structures made from technical ceramics exhibit remarkably high piezo-resistive coefficients, ranging from 1000 to 4000, in both longitudinal and transverse directions. These values substantially exceed the piezo-resistive properties observed in any existing ceramic materials currently available. This makes them an ideal choice for pressure sensors to be utilized in aerospace, automotive, and chemical industrial plants.

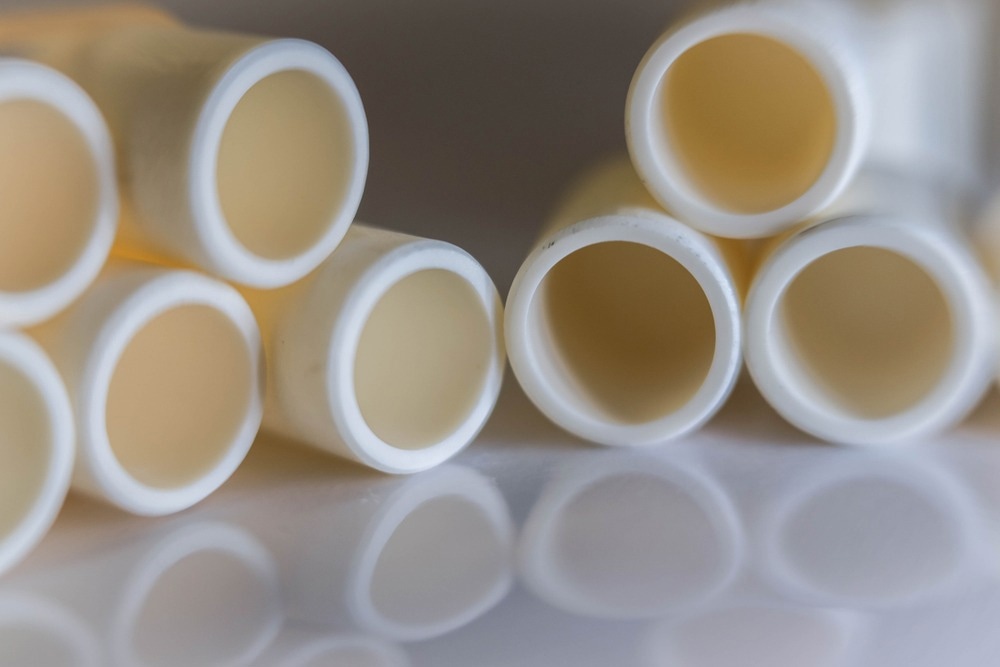

Image Credit: WildSnap/Shutterstock.com

Besides functioning as pressure sensors utilizing piezo-resistivity, PDCs can serve as heat flux sensors, temperature sensors, and hot-wire anemometers.

Technical ceramics are also used in cutting blades and sharpeners as they offer numerous crucial advantages. These include an extended lifespan of potentially up to 100 times that of traditional steel counterparts. The field of technical ceramic engineering and production tools delivers unparalleled durability and precision for a wide range of cutting and sharpening applications. These applications encompass healthcare industry blades, pharmaceutical capsule cutting tools, and large ceramic trimming blades.

Latest Trends and Hot Topics

Advanced thermal ceramics are being researched all over the world extensively. A hot topic of research is understanding the ins and outs of the degradation of thermal barrier coatings. The latest article published in Archives of Computational Methods in Engineering has discussed this matter thoroughly.

Research studies have been dedicated to exploring the resilience of thermal barrier coatings (TBCs), which are liable to oxidation, corrosion, and deterioration caused by sulfates and foreign object damage. The formidable challenge of combating hot rust degradation is particularly relevant when dealing with advanced ceramic materials exposed to elevated temperatures. Researchers are performing experimental studies to understand the mechanics of causes and progression of damage and to find optimal solutions.

Implementation of Finite Element methods in conjunction with a Machine learning-based approach to study the effects of high-velocity impact is another hot topic in the modern technical ceramics domain. This has been discussed in detail in the latest issue of Ceramics International. This confirms that, like all other industries, the modern ceramics industry has also resorted to the implementation of Artificial Intelligence for improvements.

The development of next-generation efficient ceramic 3D printers is another interesting sub-domain of the field. Ceramic on-demand extrusion (CODE) is a slurry-based 3D printing method that is being studied for the fabrication of technical ceramics. As per a recent article in Future Publishing, the procedure involves the formation of a green body through layer-by-layer printing. After the completion of each layer's printing, a heat lamp is utilized to partially and evenly dry the printed layer. Then, the layers below the topmost layer are immersed in an oil bath to prevent moisture evaporation from the sides of the component, effectively preserving its moisture content.

Market Analysis

Following research findings, the high-growth ceramics market is forecasted to reach a market size of approximately $169.3 billion by the year 2030. This was published by Markets and Markets. The growing demand within the construction, healthcare, and transportation sectors drives this growth. It is worth noting that regional markets, specifically Asia Pacific, North America, and Europe, are anticipated to witness significant expansion in this regard.

Morgan Advanced Materials, a Germany-based company named Ceram Tec-Etec GmbH, Coorstek, Inc., and KYOCERA corporation are among the major revenue generators. Coorstek, Inc.

The company provides a range of products, including transparent ceramics, technical ceramics, electronics ceramics, electrical ceramics, ceramic matrix composites, ceramic textiles, bio-ceramics, and piezo-ceramics. Additionally, the company has expanded its geographical footprint and market presence by acquiring various companies, including Covalent Materials Corporation and ANCeram GmbH, allowing it to diversify into different markets.

Future Perspective

For progress in the field of advanced technical ceramics, upcoming research studies should place a strong emphasis on two key areas. Firstly, there's a need for the fabrication of innovative materials that exhibit intensified resistance to high-temperature corrosion.

Simultaneously, efforts should be dedicated to refining the processes involved in manufacturing thermal coatings. Additionally, there's a critical requirement for innovation in techniques used to accurately and efficiently evaluate the durability and performance of advanced ceramics.

Lastly, research initiatives should be channeled towards the design and production of high-performance ceramic components essential for various system applications, thereby ensuring both reliability and efficiency.

The Current State of the Global Semiconductor Market

References and Further Reading

Awadaate, P., 2023. 10 High Growth Opportunities in the Global Technical Ceramics Market Trends & Forecast. [Online]

Available at: https://www.linkedin.com/pulse/10-high-growth-opportunities-global-ceramics-market-trends-awadaate/

Ross, L. K., 2023. Advanced Ceramics: Background, Types, and Applications. [Online]

Available at: https://www.preciseceramic.com/blog/advanced-ceramics-background-types-and-applications.html

Iqbal, A., & Moskal, G. (2023). Recent Development in Advance Ceramic Materials and Understanding the Mechanisms of Thermal Barrier Coatings Degradation. Archives of Computational Methods in Engineering, 1-42. Available at: https://doi.org/10.1007/s11831-023-09960-7

Choppala, S. et. al. (2023). Next generation of advanced ceramic 3D printers. Future Technology, 2(2), 36-42. Available at: https://doi.org/10.55670/fpll.futech.2.2.5

Wen, Q. et. al. (2022). Si-based polymer-derived ceramics for energy conversion and storage. Journal of Advanced Ceramics. 11. 197-246. Available at: https://doi.org/10.1007/s40145-021-0562-

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.