ATEX (French: “ATmosphère EX- plosible”) represents a European directive governing devices and protective systems employed in potentially explosive environments. Since April 18, 2014, the ATEX product directive RL 2014/34/EU has been in effect.

It is a legal safeguard for individuals laboring in hazardous surroundings or those susceptible to explosive incidents.

The ATEX directive 1999/92/EG outlines the requirement for plant operators to create an explosion protection document within a risk assessment, designating areas with explosive atmospheres into zones.

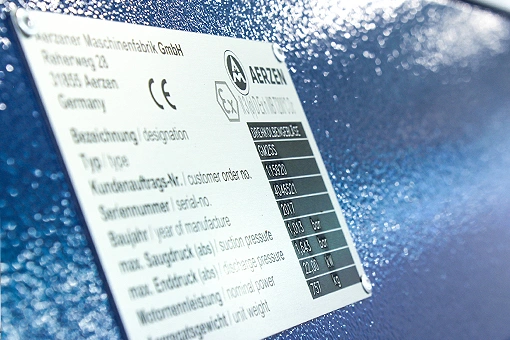

Solutions according to ATEX Directives Explosion protection badge on a Delta Blower GM3S. Image Credit: Aerzener Maschinenfabrik GmbH

The EU directives for explosion protection play an important role, among others, in the chemical industry. AERZEN always offers suitable solutions with its products. Image Credit: Aerzener Maschinenfabrik GmbH

The EU directives for explosion protection play an important role, among others, in the chemical industry. AERZEN always offers suitable solutions with its products. Image Credit: Aerzener Maschinenfabrik GmbH

Products for Nearly All ATEX Zones

AERZEN provides a comprehensive product range tailored for almost all ATEX zones. This assortment is rooted in decades of practical know-how, as AERZEN's compressor and blower packaged units have been long-standing fixtures in extremely challenging workplace environments.

As the cornerstone of ATEX-compliant plant design lies in sound counsel, AERZEN's engineers engage in in-depth discussions with customers regarding project specifics before taking any actions.

They gather pertinent ATEX-related information, including the gas and dust type, operational conditions, explosion group, temperature class (for gases), ignition temperature (for dust), ambient temperature, and frequency converter operation.

Once this information is gathered and assessed, the plant can be classified into one of three categories, following the ATEX product directive RL 2014/34/EU, distinguishing between normal, high, and very high safety requirements.

Image Credit: Aerzener Maschinenfabrik GmbH

As far as ATEX is concerned, no risks should be taken. Our customers can rely on the know-how that AERZEN has acquired over the decades. Analysis of the situation, comprehensive advice, and perfect translation into action are our strengths.

Horst-Ulrik Schwarz, Product Manager for Single-Stage Compressors, AERZEN

Solutions from One Source

To supply customers with precisely the product they need, AERZEN's ATEX specialists develop customized unit concepts, along with all necessary documentation and related accessories, following the ATEX product directive RL 2014/34/EU.

Before implementing specific customer requests, AERZEN engineers review them to ensure they align with the ATEX directive.

As a result, customers receive an ATEX-compliant and TÜV-approved all-inclusive solution from one source, regardless of whether the packaged unit is used in overpressure or negative pressure applications. AERZEN adapts technologies differently based on product groups and zone types, including:

- Zone separation filter

- Special documentation

- Use of special materials for medium-contacting parts

- Ex-instrumentation

- Vibration monitoring

- Spark arrester

- Special motors according to the corresponding zone

Various Possible Applications

AERZEN products find utility in various sectors. They are used, for instance, in environmental engineering for compressing biogas and natural gas, as well as for gas feed-in. In the chemical and pharmaceutical industry, they serve to convey gas and handle degassing.

AERZEN also caters to refineries and power plant technology. The application extends to the food and plastics industries, where these products are employed for loading and unloading silos and pneumatic conveyance.

During the pneumatic conveyance of combustible or explosive bulk materials, there is a possibility of ignitable mixtures forming within the plant. Consequently, the components must be classified for different zones to implement the necessary protective measures. AERZEN provides all unit components in a suitable ATEX design.

With the TÜV-approved zone separation filter and integrated spark arrester, cost-effective alternatives to traditional protective components are at hand. In terms of legal explosion protection, AERZEN's customers can always be assured of their safety.

This information has been sourced, reviewed and adapted from materials provided by Aerzener Maschinenfabrik GmbH.

For more information on this source, please visit Aerzener Maschinenfabrik GmbH.