Boston Micro Fabrication has released a new on-demand whitepaper explaining how some of the key modern additive manufacturing techniques work and the typical achievable manufacturing performances with each method.

Additive manufacturing technologies are revolutionizing the speed at which complex structures can be prototyped.1 However, the wealth of different methods out there can make it hard to select which is the right approach for your manufacturing problem. In this e-book, Boston Micro Fabrication looks at which factors are important for the quality of your final product, such as resolution and precision, for several key manufacturing additive techniques.

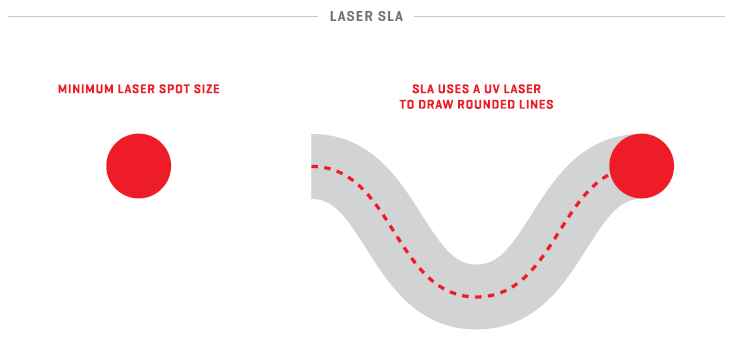

Stereolithography (SLA)

Stereolithography (SLA) makes use of a rounded laser beam to draw a pattern on the target substrate. Current commercially available SLA systems can achieve an XY resolution of 50 µm, a minimum features size of 150 µm and an overall tolerance of +/- 100 µm.

Image Credit: Boston Micro Fabrication (BMF)

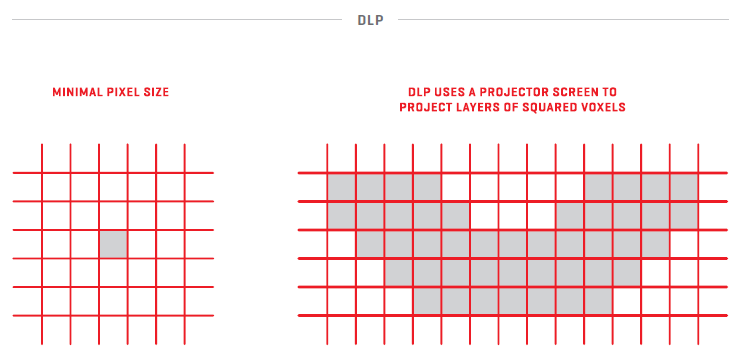

Digital Light Processing (DLP)

Digital Light Processing (DLP) is sometimes known as LCD projection but uses a flash of light from a projector to cure a particular image into a resin. The entire region is cured at once, meaning that, unlike in SLA, the laser does not have to raster over the object. Typically, DLP systems possess only Z-direction movement, altering the curable area at the expense of resolution, without accompanying XY translation.

Image Credit: Boston Micro Fabrication (BMF)

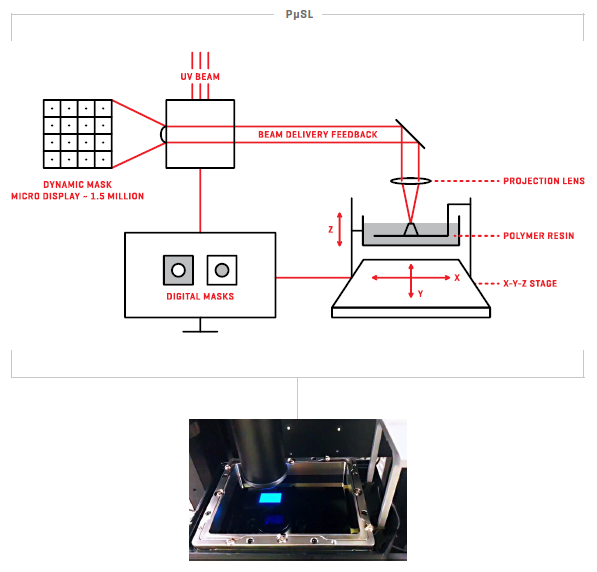

Projection Micro Stereolithography (PµSL)

Projection Micro Stereolithography (PµSL) has many similarities to DLP but was developed as a way of being able to print larger parts or multiple parts with higher tolerances at higher resolution. Achieving this means including XY translation for the beam delivery as well as the inclusion of an extra lens to focus the beam to achieve smaller spot sizes for improved resolution.

Boston Micro Fabrication has a special top-down design for its instrumentation, which simplifies and improves the manufacturing process. As a result, Boston Micro Fabrication’s systems can achieve XY resolution down to 2 µm, a minimum feature size of 10 µm, and a high dimension tolerance of up to +/- 10 µm.

Image Credit: Boston Micro Fabrication (BMF)

Download the White Paper to Learn More

References and Further Reading

- Singh, J., Singh, R. P., & Pandey, P. M. (2023). Additive Manufacturing Techniques: Fundamentals, Technological Developments, and Practical Applications. In Handbook of Post-Processing in Additive Manufacturing (pp. 1-34). CRC Press.

This information has been sourced, reviewed and adapted from materials provided by Boston Micro Fabrication.

For more information on this source, please visit Boston Micro Fabrication.