Depending on the origin of waste material, its composition can vary considerably. As a result, there are various ways to utilize waste, ranging from straightforward landfill disposal to incineration for energy generation or recycling of the materials.

Consequently, a wide array of analytical techniques are employed to assess different parameters of interest, each tailored to the specific usage of the waste.

When depositing domestic or industrial waste, sewage sludge, contaminated excavated soil, road waste (containing bitumen and tar), rubble from building sites, and other materials, the measurement of total organic carbon (TOC) is crucial for waste classification.

For instance, in accordance with the European Landfill Directive, the TOC concentration of waste is a determining factor for its assignment to a landfill class, among other parameters.

At dumping sites, organic waste components are subject to microbial decomposition, which leads, on the one hand, to the formation of landfill gases, causing a smell nuisance and contributing to the greenhouse effect.

On the other hand, decomposition products such as organic acids contribute significantly to the mobilization of heavy metals by complexation reactions. This leads to their transfer into the lower soil layers and serious seeping or groundwater contamination. To prevent this, waste materials with increased TOC content need to be treated differently.

The fundamental procedures for determining the TOC parameter in solids are outlined in DIN EN 15936 (also EN 13137). Various techniques can be utilized, all involving the treatment of the sample with an inorganic, non-oxidizing acid as one step of the complete procedure.

The carbonates in the sample react with the acid to form CO2, which is either quantitatively determined using the indirect method (TOC = TC - TIC) or eliminated from the sample to directly measure the TOC afterward.

Materials and Methods

The determination of total organic carbon (TOC) in all waste samples followed the direct method outlined in EN 15936 or EN 13137. To achieve this, the samples were carefully weighed into ceramic sample boats, with varying sample amounts chosen based on the homogeneity of each particular sample.

Higher sample weights were used for samples with a more heterogeneous appearance. Following the weighing step, an acidification process was carried out to remove carbonates/hydrogen carbonates (TIC), followed by subsequent drying.

The prepared boats were then positioned on the sampler FPG 48 and automatically fed into the furnace of the analyzer. Different method settings, such as temperature, sample introduction speed, and hold positions, were applied depending on the specific waste matrices.

The combustion occurred within a robust and catalyst-free ceramic combustion tube at temperatures equal to or greater than 1,000 °C in a pure oxygen atmosphere. The high combustion temperature and oxygen surplus ensured the quantitative oxidation of all organic compounds post-TIC elimination.

Throughout the combustion process, carbon dioxide was generated and carried by the carrier gas into the Focus Radiation NDIR detector. En route from the furnace to the detection system, the combustion gases underwent purification through multiple stages of particle removal, moisture absorption, and halogen absorption.

Sample Preparation

The different waste samples had already been homogenized (crushed or ground) to achieve a satisfactory particle size ranging from 1 to 3 mm.

In particular, road waste and industrial waste displayed an erratic and non-uniform sample structure characterized by uneven particle sizes and varied coloring. All samples were weighed into ceramic sample boats without further homogenization.

Acidification of the samples was achieved using an acid dispenser, where 500 µL of 10% HCl was added to each. To ensure the complete elimination of Total Inorganic Carbon (TIC), a few drops of 25% HCl were added until no more gas (CO2) production was observed.

Following this, all sample boats were placed on a heating plate set at 40 °C and left to dry overnight for approximately 14 hours.

A set of three boats for each sample, along with an additional certified reference material, was prepared following the described procedure.

Calibration

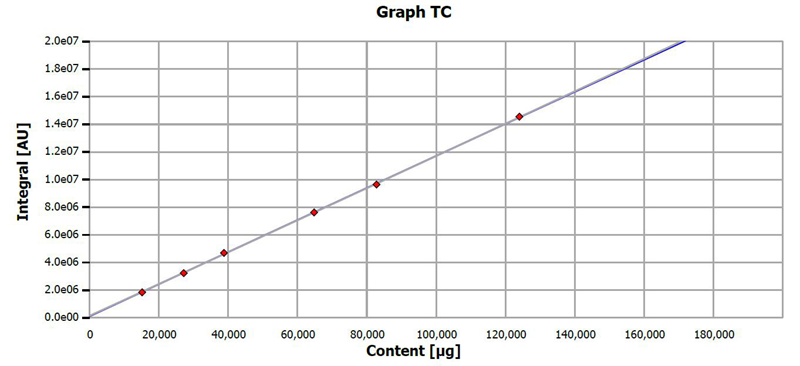

The calibration process for the solid TOC analyzer involved analyzing a single standard substance (Coal CRM) with varying sample weights, resulting in a calibration curve that spans a wide concentration range.

The coal standard (TC = 62.53%) was weighed in different portions, starting with approximately 20 mg directly into ceramic sample boats. These boats were then introduced into the furnace of the solid TOC analyzer using the FPG 48 autosampler and subjected to combustion. The calibration curve is presented in Figure 1.

Table 1. Calibration. Source: Analytik Jena US

| Parameter |

Calibration

Standard |

Carbon

Content [%] |

Weight [%] |

Calibrated Range

[mg Cabsolute] |

| TC |

Coal Standard (CRM) |

62.53 |

24 ‒ 200 |

15 ‒ 125 |

Figure 1. Calibration curve. Image Credit: Analytik Jena US

Instrument Settings

Measurements were performed with a multi N/C 2100S duo consisting of the multi N/C 2100S basic unit equipped with AS 60 and HT 1300 solid furnace combined with the FPG 48 solid sampler.

The following instrument configurations may alternatively be used for the determination of TOC in waste samples of different origins by direct or differential methods.

Table 2. Further Instrument configurations. Source: Analytik Jena US

| Instrument configuration |

Operation

mode |

Additional parameters

/ benefits |

multi N/C 3100 duo

(multi N/C 3100 + AS vario ER

+ HT1300 + FPG 48) |

Automated determination of TOC, direct method |

NPOC/TOC/TIC/TC determination in water samples,

upgradable with TNb option (CLD, ChD) for water samples |

multi N/C 2100S + HT 1300

multi N/C 3100 + HT 1300 |

Manual determination of TOC, direct method |

NPOC/TOC/TIC/TC determination in water samples,

upgradable with TNb option (CLD, ChD) for water samples |

| multi EA 4000 + FPG 48 |

Automated determination of TOC, direct method |

Upgradable for TS (Total Sulfur) and TCl (Total Chlorine)

determination in solid samples |

| multi EA 4000 + FPG 48 + TIC auto |

Automated determination of TOC and/or

TIC, difference or direct method, automatic acidification |

Upgradable for TS (Total Sulfur) and

TCl (Total Chlorine) determination in solid samples |

All the instruments mentioned above feature a robust ceramic combustion tube that is unaffected by high levels of alkali or earth alkali metals or acid vapors.

The combustion temperatures, reaching up to 1,300 °C (multi N/C duo systems) or 1,500 °C (multi EA 4000 configurations), ensure the quantitative digestion of all carbon compounds.

Method Parameters

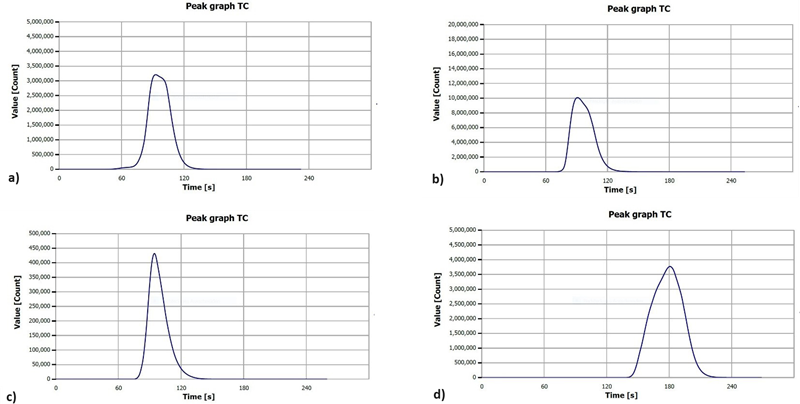

Waste samples from diverse origins can exhibit significant variations in composition, leading to distinct combustion behaviors. In cases where samples have a substantial organic matter content, such as biowaste, it is crucial to regulate the anticipated intense combustion process to prevent misleading results.

This control is achieved by gradually introducing the sample into the hot furnace and additionally covering it with an inert retarding material, such as annealed quartz sand. The parameter settings for the combustion and sample introduction of various waste samples are outlined in Table 3.

Table 3. Method settings multi N/C 2100S duo. Source: Analytik Jena US

| Matrix |

Parameter |

Combustion temperature [°C] |

Sample introduction speed [mm/min] |

Holding position autosampler [mm] |

Waiting period at holding position [s] |

Additives |

| Biowaste |

TC |

1,000 |

300 |

100 |

60 |

Quartz sand |

| Contaminated soil |

TC |

1,200 |

500 |

- |

0 |

- |

| Road waste |

TC |

1,200 |

100 |

100 |

60 |

Quartz sand |

| Industrial Waste |

TC |

1,200 |

300 |

- |

0 |

- |

Results and Discussion

The analysis results for various waste samples are presented in Table 4, with measurements conducted in triplicates. The achieved standard deviations (SD) fall within the anticipated range for heterogeneous matrices like waste.

The reproducibility can be improved by putting more effort into sample homogenization (e.g., milling with cooled mills for samples like road waste containing tar). Routine laboratories frequently skip labor-intensive homogenization procedures and accept Relative Standard Deviation (RSD) values of up to 5%.

Typical measurement curves are depicted in Figure 2.

Table 4. Results. Source: Analytik Jena US

| Sample ID |

Sample weight [mg] |

TOC Average ± SD [%] |

RSD [%] |

| Biowaste |

approx. 300 |

7.46 ± 0.21 |

2.8 |

| Contaminated Soil |

approx. 500 |

5.23 ± 0.10 |

1.9 |

| Road Waste |

approx. 500 |

27.1 ± 0.81 |

3.0 |

| Industrial Waste |

approx. 500 |

14.4 ± 0.49 |

3.4 |

CRM (coal) 56.23 %

TC NCS FC 28009J |

approx. 50 |

55.9 ± 0.45 |

0.8 |

Figure 2. Typical measurement curves of a) biowaste, b) contaminated soil, c) road waste, d) industrial waste. Image Credit: Analytik Jena US

Summary

The multi-N/C duo systems have proven to be highly suitable for efficiently and reliably analyzing waste samples of diverse origins using the direct method of TOC determination. Sample preparation can be executed directly within the sample boats for a batch of samples, minimizing preparation time and manpower.

The subsequent sample analysis is fully automated, with the FPG 48 sampler capable of running a sequence of up to 48 samples, employing different method settings for various sample matrices.

Straightforward calibration routines and the inclusive wide-range Focus Radiation NDIR detector allow for a broad measuring range of up to 500 mg C absolute for all multi-N/C duo instruments. This eliminates the need for repeated analyses for samples with unexpectedly high concentrations.

The preparation and measuring procedures align fully with EN 15936. Moreover, the multi N/C duo systems are well-suited for the automated analysis of TOC (TIC, TC), NPOC, POC, and TNb in water samples without laborious hardware modifications to the instrument.

Switching the configuration setup in the software and loading the desired method can be effortlessly accomplished with a few clicks of a mouse, transforming the solid TOC analyzer into a fully automated liquid analyzer or vice versa.

Figure 3. multi N/C 2100S duo. Image Credit: Analytik Jena US

References

- EN 13137 Characterization of waste - Determination of total organic carbon (TOC) in waste, sludges and sediments

- EN 15936: Sludge, treated biowaste, soil, and waste - Determination of total organic carbon (TOC) by dry combustion

This information has been sourced, reviewed and adapted from materials provided by Analytik Jena US.

For more information on this source, please visit Analytik Jena US.