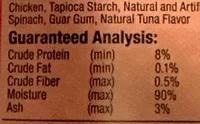

In contrast to the comprehensive nutritional requirements specified for human food, pet food labeling in North America must only report four key values in their Guaranteed Analysis: protein, fat, fiber, and moisture.

Image Credit: LECO Corporation

Additional nutrients are required if specifically mentioned on the label, but manufacturers also have the option to voluntarily include more nutrients to offer consumers additional information or highlight the nutritional value of their products. Interestingly, one such voluntary "nutrient" commonly found on labels is "ash."

The inclusion of ash in the Guaranteed Analysis does not signify the presence of actual ash in the food. Instead, it explains the method used to determine the mineral content in the pet food.

Image Credit: LECO Corporation

The mineral content in pet food, such as calcium, iron, zinc, phosphorus, and others, does not undergo combustion, unlike other components like fat, protein, and fiber. A fast method to test for general mineral content involves taking a food sample, weighing it, burning it until no further mass loss occurs, and then re-weighing it.

The residue, known as ash, represents the mineral content and can be reported to regulators or included on the label.

As Michael Jakob highlights in a recent Feed & Additive article, mass loss on ignition/combustion conducted with an air oven or a muffle furnace is one of the most common approaches to determining ash content.

Comparable methods, at lower temperatures, can be applied to determine moisture in food samples. This is another value of significance for labels and regulations. This form of thermogravimetric analysis is widely accepted for food and feed analysis in laboratories worldwide.

This process is typically lengthy and labor-intensive. Samples need to be measured and documented at various intervals, with care taken not to introduce atmospheric contamination during the entire process.

Given that the analysis concludes when the weight stabilizes, it often requires multiple hours to guarantee that the sample is adequately prepared, resulting in a significant waste of time and energy.

Many automated thermogravimetric analyzers are relatively small and capable of managing only one or two samples simultaneously. This limitation can create a seemingly endless cycle of repetitive testing.

Image Credit: LECO Corporation

LECO's TGA801 breaks the cycle of repetitive tasks with its macro thermogravimetric analysis, strategically designed to optimize efficiency, analysis time, and sample batch throughput.

Its automated carousel can handle 19 samples concurrently, each with macro sample weights of up to 5 grams. The operator simply needs to choose the method and log in the initial sample weights, leaving the TGA801 to take care of the rest.

Throughout the analysis sequence, the sample carousel systematically moves each crucible onto the integrated balance pedestal, consistently monitoring the weight and documenting all measurements. Once moisture weight constancy is achieved for all samples, the TGA801 automatically raises the temperature for ash determination.

The analysis concludes precisely when weight constancy is reached for the final step, resulting in time and cost savings and eliminating uncertainty.

During this process, the operator can step away from the instrument and attend to other tasks. Cornerstone® Mobile, LECO's mobile software link to its instruments, is capable of providing alerts upon cycle completion or in the event of any issues arising.

This information has been sourced, reviewed and adapted from materials provided by LECO Corporation.

For more information on this source, please visit LECO Corporation.