Understanding and maintaining the precise composition of gases is vital for ensuring the efficiency and longevity of hydrogen fuel cells. This article delves into the significance of gas analysis in hydrogen fuel cells and its impact on the performance of this cutting-edge technology.

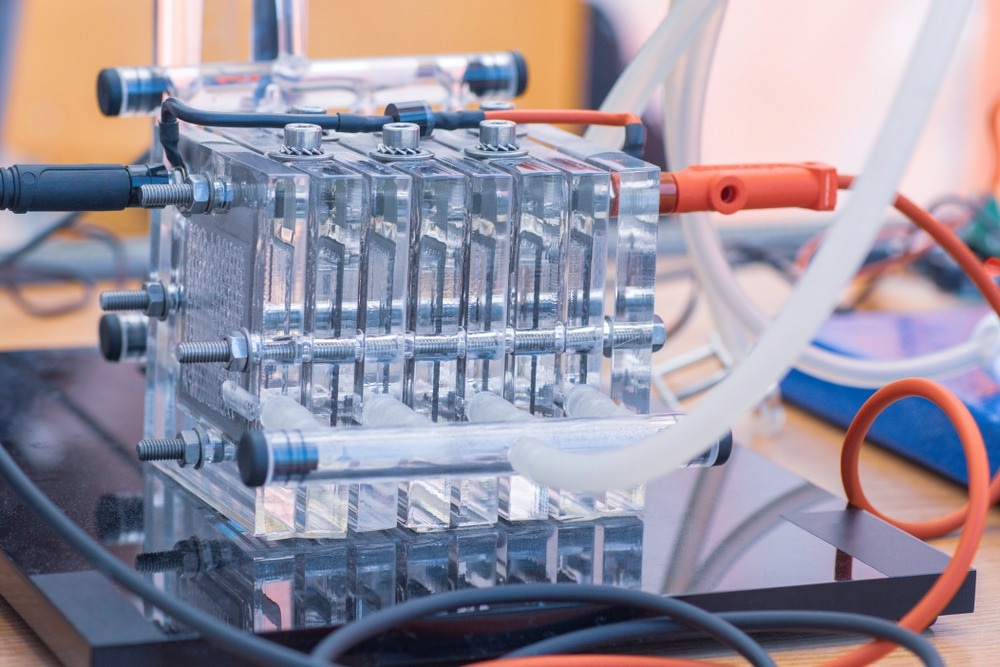

Image Credit: Kaca Skokanova/Shutterstock.com

Working and Efficiency of Hydrogen Fuel Cells

The key components of a fuel cell include an anode, a cathode, and an electrolyte. At the anode, hydrogen molecules are split into protons and electrons that pass through the electrolyte and external circuits, respectively, generating current and producing water as a byproduct.

The efficiency of hydrogen fuel cells is highly dependent on the purity and composition of the gases involved since any impurities, either moisture, carbon monoxide, trace amounts of other gases in the hydrogen feedstock, or any other contaminants can significantly hinder performance. These impurities can poison catalysts, degrade electrolyte materials, and ultimately reduce the overall efficiency of the fuel cell.

Gas Analysis in Hydrogen Production

Gas analysis plays a crucial role in the entire lifecycle of hydrogen fuel cells, starting from hydrogen production. Hydrogen production methods, such as steam methane reforming (SMR), electrolysis, and biomass gasification, must be monitored to ensure the purity of the generated hydrogen. Trace impurities, even in small concentrations, can have a detrimental impact on the performance of fuel cells over time.

For instance, in steam methane reforming, monitoring the gas composition helps identify and mitigate the presence of carbon monoxide that can poison the catalysts in fuel cells, leading to a decline in efficiency and increased degradation of cell components. Real-time gas analysis allows for adjustments in the production process to maintain the desired purity levels.

Gas Analysis During Hydrogen Storage and Transportation

Gas analysis is crucial during hydrogen storage and transportation stages to prevent contamination and ensure the integrity of the stored hydrogen. Different storage methods, such as compressed hydrogen gas, liquid hydrogen, and metal hydrides, each have unique challenges.

Compressed hydrogen, for instance, must be free from impurities that could corrode storage containers or affect the fuel cell performance upon usage. Gas analysis techniques, such as mass spectrometry and gas chromatography, are employed to detect and quantify impurities in stored hydrogen, enabling proactive measures to maintain purity.

In the case of hydrogen transportation, pipelines, and tanks must be periodically monitored for leaks or contaminants. Regular gas analysis helps identify deviations from the desired composition and ensures the safe and efficient transport of hydrogen to its destination.

Gas Analysis in Fuel Cell Operation

During the operation of hydrogen fuel cells, continuous gas analysis is essential to monitor the composition of gases within the cell. Various factors can influence gas composition within fuel cells, including operating conditions, temperature, and the quality of the hydrogen feedstock; hence, this real-time feedback allows for adjustments to optimize performance and prevent long-term damage.

Gas analysis systems integrated into fuel cell setups can detect and quantify the presence of carbon monoxide and other impurities, triggering automatic adjustments or shutdown procedures to prevent damage. For instance, in addition to impurity monitoring, gas analysis is crucial for assessing the water content within fuel cells since excessive moisture can lead to fuel cell flooding, disrupting the electrochemical reactions and reducing power output. Advanced gas analysis techniques, such as infrared spectroscopy, are employed to measure moisture levels accurately and maintain the optimal operating conditions for fuel cells.

Recent Development

In a 2018 study focusing on hydrogen fuel cell (HFC) technology in Korea, researchers conducted a comprehensive well-to-wheel (WTW) greenhouse gas analysis of various hydrogen production pathways for fuel-cell electric vehicles (FCEVs). The study covered naphtha cracking, steam methane reforming, electrolysis, and coke oven gas purification. The results, comparing different hydrogen production methods, revealed WTW emissions ranging from 32,571 to 249,332 g-CO2 eq./GJ or 50.7 to 388.0 g-CO2 eq./km. Notably, the landfill gas pathway exhibited the lowest emissions, emphasizing the importance of diverse hydrogen production considerations in enhancing environmental sustainability for FCEVs.

Commercial Example of Hydrogen Fuel Cell Analyzer

Hiden Analytical is one of the leading gas analysis solutions providers and offers cutting-edge hydrogen fuel cell analysis technology. Their CATLAB-PCS system integrates a microreactor and mass spectrometer, providing a platform for in-depth catalysis analysis with fast response times and integrated air-cooling for accurate characterization. Hiden Analytical's QGA compact bench-top system is designed for high-purity gas analysis in hydrogen fuel cells, ensuring compliance with strict standards to prevent electrode poisoning and maintain fuel cell integrity.

Future Prospects

The future of gas analysis in hydrogen fuel cells holds promising advancements. As technology continues to evolve, the integration of sophisticated gas analysis systems, exemplified by innovations from Hiden Analytical, will play a pivotal role in ensuring the efficiency and reliability of hydrogen fuel cells. Ongoing research, as demonstrated in the 2018 Korean study, highlights the commitment to exploring diverse hydrogen production pathways for fuel-cell electric vehicles. The focus on minimizing greenhouse gas emissions underscores a growing awareness of environmental sustainability. As the field progresses, ongoing developments in gas analysis techniques will contribute to further enhancing the performance and environmental credentials of hydrogen fuel cell technology.

Membrane Inlet Mass Spectrometry for Gas Analysis

References and Further Reading

Consonni, S., Mastropasqua, L., Spinelli, M., Barckholtz, T. A., & Campanari, S. (2021). Low-carbon hydrogen via integration of steam methane reforming with molten carbonate fuel cells at low fuel utilization. Advances in Applied Energy. https://doi.org/10.1016/j.adapen.2021.100010

Garzon, F., Uribe, F. A., Rockward, T., Urdampilleta, I. G., & Brosha, E. L. (2006). The impact of hydrogen fuel contaminates on long-term PMFC performance. ECS Transactions. https://doi.org/10.1149/1.2356190

Hiden Analytical. (2021, December 17). Applications of Gas Analyzers in the Automotive Industry. AZoM. Retrieved on November 18, 2023 from https://www.azom.com/article.aspx?ArticleID=15885

Murugan, A., & Brown, A. S. (2015). Review of purity analysis methods for performing quality assurance of fuel cell hydrogen. International Journal of Hydrogen Energy. https://doi.org/10.1016/j.ijhydene.2015.01.041

Yoo, E., Kim, M., & Song, H. H. (2018). Well-to-wheel analysis of hydrogen fuel-cell electric vehicle in Korea. International Journal of Hydrogen Energy. https://doi.org/10.1016/j.ijhydene.2018.08.088

Zygo Corporation. (2023, June 14). Characterizing Fuel Cell Surfaces. AZoM. Retrieved on November 18, 2023 from https://www.azom.com/article.aspx?ArticleID=22754

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.