In the fields of metallurgy and materials science, experts are always aiming towards better products with enhanced physical and chemical properties. This is usually done by performing specialized processes under specified conditions. Cold-working and hot-working different types of steel products are useful in augmenting their properties.

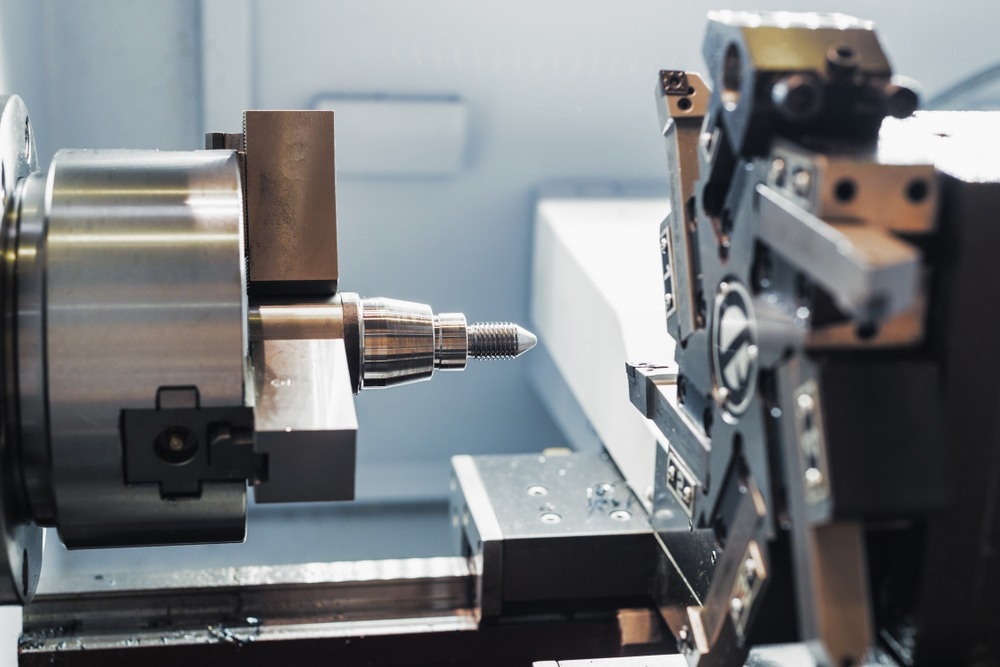

Image Credit: Nordroden/Shutterstock.com

An Overview of Cold Working of Steel

The process of cold working involves the strengthening of steel material by physically manipulating the material below the recrystallization temperature. The recrystallization temperature is defined as the temperature at which new defect-free crystalline grains replace the original ones present in the material.

The cold working process does not involve significant recovery. Instead, it results in the accumulation of internal and residual stresses within the metal. Additionally, there is a potential for cracks or pores in the metal to propagate, and new cracks may form during this cold working process. Notably, the strengthening in this process occurs without the utilization of heat.

What are the Different Processes for Cold Working?

There are four common and famous types of cold working processes, including squeezing, bending, shearing, and drawing. Squeezing includes several methods, such as rolling, extrusion, and cold forging.

Cold-rolled steel is put under severe stress. Strain hardening occurs during this process, which can increase the hardness by about 20 percent compared to its original state. Another common process is cold forging, which involves placing the steel or targeted metal between two dies, followed by pounding the dies. This leads to the targeted metal acquiring the shape of the die.

Bending methods are preferred for the shaping of steel alloys. Shearing involves splitting the steel sheets into different strips.

Steel slitting is a procedure designed to cut a broad master coil into narrower strands with consistent measurements. Manufacturers feed the large stainless steel through a machine known as a slitter, and then the resulting strands are recoiled into a finished coil. It's worth noting that the machine's knives can leave a burr on the slit edge.

Benefits and Applications

Cold-worked steel components are frequently employed in industries such as aerospace and automobile industry. Several essential processes and equipment for medical applications incorporate cold-worked steel, such as pacemaker stamping and hypodermic needles. Cold-work steel is used to manufacture rivets, gaskets, and shielding.

In addition to increasing the strength of metal, cold rolling also contributes to smoother surfaces. Cold-rolled steel can be as high as ten times smoother than hot-rolled steel in terms of roughness height, which measures surface irregularities. This attribute positions cold working as a preferred method for producing the smooth metal surfaces commonly found in consumer goods.

Cold working is economically efficient as it does not generate scrap metal, which is often a byproduct of other processes. Unlike hot working, cold working does not require soaking pits and furnaces, further contributing to its cost-effectiveness.

A Peek into Hot Working

Hot working involves processes in which metals are plastically deformed at temperatures above their recrystallization temperature. Operating above the recrystallization temperature enables the material to undergo recrystallization during deformation. This is crucial as recrystallization prevents strain hardening, thereby maintaining low yield strength and hardness while preserving high ductility.

Steel is commonly hot worked at temperatures around 1300°F (700°C), involving the shaping of metal close to its molten state. In any hot working process, the critical factor is the temperature control of the workpiece, as approximately 90% of the energy applied to the workpiece transforms into heat.

Methods and Advantages of Hot Working

Hot rolling is a conventional working process utilized for various purposes. In this process, steel undergoes passage through a pair of rollers moving in opposite directions but with the same speed. This action flattens, lengthens, and reduces the cross-sectional area of the steel, resulting in uniform thickness.

Hot forging holds significant commercial importance, finding widespread use in various industries for the production of diverse products. It entails shaping metal through localized compressive forces, involving heating, deforming, and shaping the metal piece. These forces are applied through a manual hammer or hammer machine and die. Hot forging is particularly valuable in the manufacturing of industrial components such as crane hooks, cranks, crankshafts, and wrenches.

Hot working is well-suited for bulk production tasks. The material's elevated temperature provides increased ductility, allowing for unrestricted hot-working of the metal. The higher temperature reduces shear stress, requiring significantly less force for the necessary deformation. Moreover, hot working effectively eliminates various imperfections caused by gas pores and composition differences in the material.

Comparison of Mechanical Properties of Hot and Cold Worked Steel at Elevated Temperatures

The structural integrity and redundancy in the design of steel buildings may prevent their collapse in the event of a fire hazard. Consequently, the residual mechanical properties of steel materials become crucial indicators for assessing the post-fire performance of the overall structure and the potential reuse of steel members.

In an article published in Construction and Building Materials, researchers compared the residual mechanical properties of hot and cold worked steel at high temperatures such as fire conditions.

In both hot-rolled and cold-formed steels, the elastic modulus remains largely unchanged following exposure to fire. When air-cooled, hot-rolled steels exhibit reductions in yield strength and ultimate strength after heating beyond 600°C. Conversely, cold-formed steels show early strength reduction, commencing from heating to 300°C.

Hot-rolled steels demonstrate improved ductility under air cooling conditions, while ductility reduction is observed when water-cooled from elevated temperatures. In contrast, the post-fire ductility values of cold-formed steels consistently exhibit improvements.

Both hot-working and cold-working for steel have their distinct advantages. These methods are employed for various industrial processes. However, the choice of any particular process depends on the intended application and the desired properties.

Glass-Ceramic Materials for Dental and Orthopedic Implants

References and Further Reading

American Galvanizers Association, (2023). Cold Worked Steels. [Online]

Available at: https://galvanizeit.org/design-and-fabrication/design-considerations/cold-worked-steels

Garcia, A., (2023). Hot Working and Cold Working; Its Advantages, Disadvantages. [Online]

Available at: https://mechathon.com/hot-working-and-cold-working/

Kumar, A., (2021). Hot Working: Definition, Methods, Working Process, Advantages, Disadvantages, Application. [Online]

Available at: https://themechanicalengineering.com/hot-working/

Madhu, (2019). Difference Between Hot Working and Cold Working. [Online]

Available at: https://www.differencebetween.com/difference-between-hot-working-and-vs-cold-working/

Metallurgy For Dummies, (2023). Metal Hot Working Process. [Online]

Available at: https://www.metallurgyfordummies.com/metal-hot-working-process.html#:~:text=Steel%20is%20typically%20hot%20worked,workpiece%20is%20converted%20into%20heat.

Yu et. al. (2019). Mechanical properties of hot-rolled and cold-formed steels after exposure to elevated temperature: A review. Construction and Building Materials. 213. 360-376. Available at: https://doi.org/10.1016/j.conbuildmat.2019.04.062

PMPA, (2023). 5 Benefits of Cold Work in Steels. [Online]

Available at: https://www.pmpa.org/5-benefits-of-cold-work-in-steels/

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.