Homogenization is crucial in soy milk manufacturing, improving its taste and stability. This process involves exposing the liquid to intense shearing and breaking down large fat globules and protein clusters.

Bettersize provides soy milk particle analysis using two instruments: Bettersizer S3 Plus and BeVision S1. This ensures the overall quality of the soy milk product and creates a homogeneous liquid that effectively prevents fat floating and protein settling.

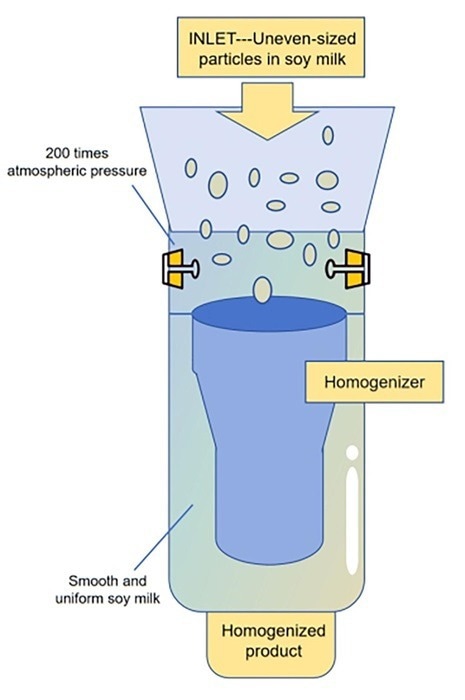

To achieve a smoother texture and enhance the bioavailability of soy milk, the manufacturing process utilizes high-pressure homogenization. This vital step involves subjecting soy milk to up to 200 times atmospheric pressure, forcing it through the narrow aperture of the homogenization valve.

Combined, the forces of shear and impact can break down large fat globules, phospholipid, and protein agglomeration, yielding smaller and uniformly dispersed particles in the soy milk. The particle size of these components is the property in soy milk utilized to monitor changes occurring during homogenization.

Figure 1. The simulated operation of a high-pressure homogenizer. Image Credit: Bettersize Instruments Ltd.

Materials and Methods

This study aims to evaluate the effect of the homogenization process on the particle size of soy milk components. The materials utilized include homogenized soy milk (referred to as sample 1) and unhomogenized soy milk (referred to as sample 2).

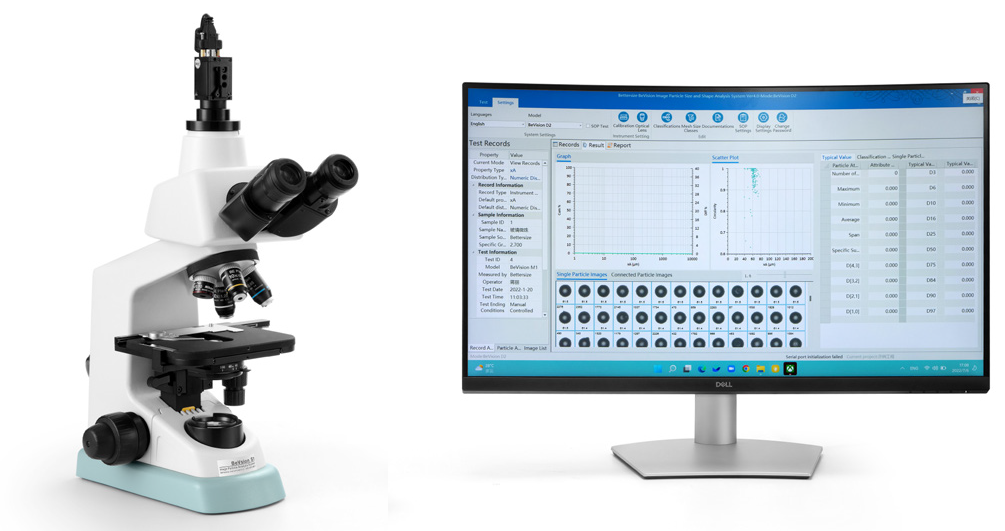

This article highlights Bettersizer S3 PLUS and BeVision S1 for particle size distribution and shape analysis.

Bettersizer S3 Plus. Image Credit: Bettersize Instruments Ltd.

The Bettersizer S3 Plus combines laser diffraction and dynamic image analysis in a single instrument, enabling the simultaneous characterization of particle size, particle shape, and size distribution over a wide dynamic range.

The BeVision S1 combines light microscopy and image analysis to deliver intuitive and accurate size and shape distributions of both powder and suspensions.

Bevision S1. Image Credit: Bettersize Instruments Ltd.

Result and Discussion

Bettersizer S3 Plus Result

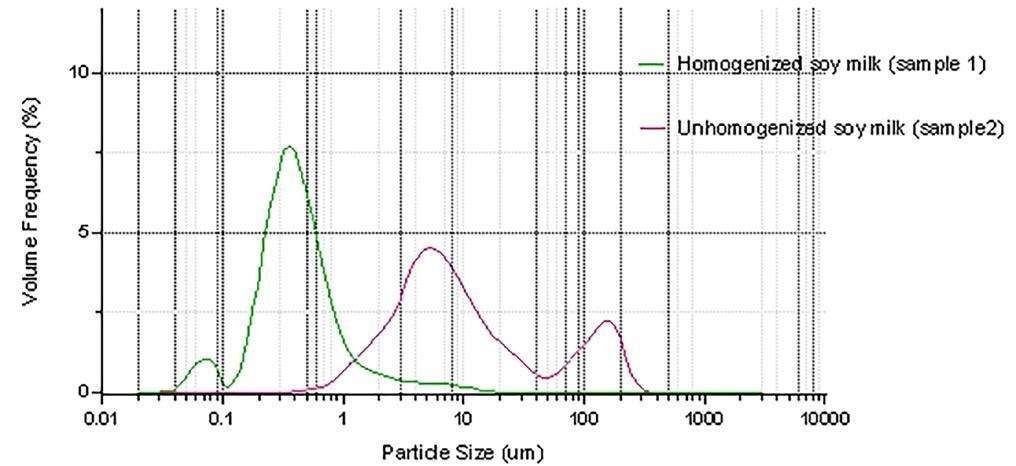

Figure 2 shows the results of these two samples. For homogenized soy milk, the median particle size is 0.355 microns, and the span of its particle size distribution is 2.833. This suggests a uniform and finely dispersed mixture.

Figure 2. Particle size distribution of homogenized and unhomogenized soy milk. Image Credit: Bettersize Instruments Ltd.

Unhomogenized soy milk has a significantly higher median particle size of 8.861 microns, with a wider span of 17.63, suggesting a more variable and less consistent distribution.

The homogenized soy milk decreased the average particle size of fat globules and protein, with a narrower size distribution. This supports the theory that homogenization can achieve a finer and more uniform liquid.

Table 1. Typical particle size values of soy milk samples. Source: Bettersize Instruments Ltd.

| Samples |

Homogenized soy milk (sample 1) |

Unhomogenized soy milk (sample 2) |

| Dv10(μm) |

0.152 |

2.763 |

| Dv50(μm) |

0.362 |

8.861 |

| Dv90(μm) |

1.161 |

159.0 |

| Span |

2.782 |

17.63 |

| D[4,3](μm) |

0.928 |

45.10 |

Within the 1 to 11 microns range, which signifies the dominant particle size range of sample 2, sample 1 displays tailing phenomena, suggesting the presence of incompletely homogenized particles. These findings indicate that additional homogenization would result in smoother soy milk with a more refined consistency.

The particle size distribution of sample 2 exhibits two significant peaks. The primary peak is at 5.07 microns, indicating a prevalent particle size in that range. A secondary peak at 154 microns indicates the presence of larger particles within the mixture.

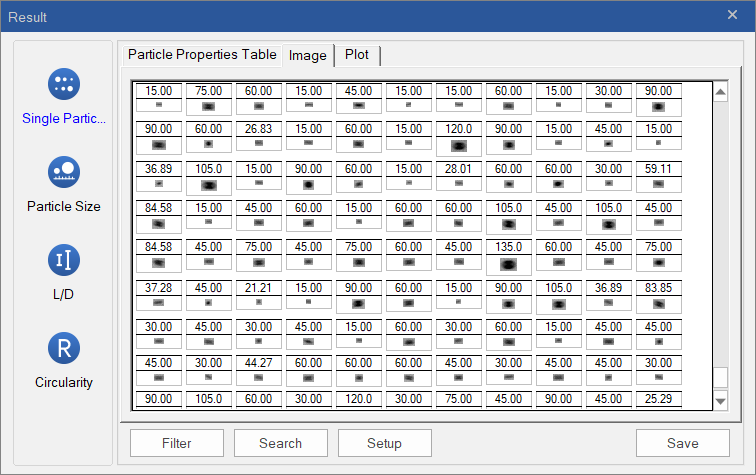

Utilizing a dynamic image analysis technique based on counting, the Bettersizer S3 Plus identifies these oversized globules and protein particles. This is achieved by examining each particle individually or by analyzing the shape and size data parameters of all particles collectively. This results in generating a number-based distribution and numerous other essential parameters, as illustrated in Figure 3.

Figure 3. The result from the dynamic image analysis of Bettersizer S3 Plus. Image Credit: Bettersize Instruments Ltd.

BeVision S1 Results

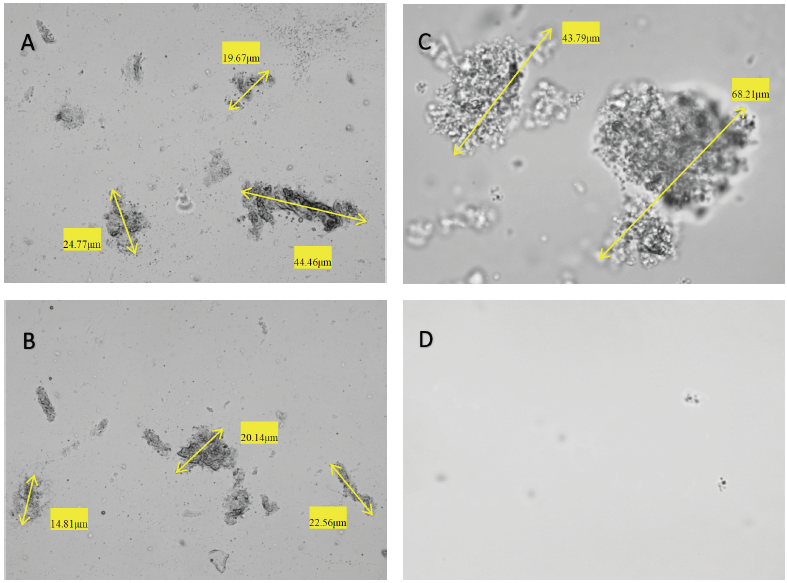

To cross-verify the components of particles identified in the dynamic image analysis, BeVision S1 offers more accurate and detailed magnified images, highlighted in Figure 4.

Under the BeVision S1, the large particles, approximately 30 microns, showcase a diverse array of interesting structures and shapes, as depicted in Figure 4 A/B/C. These bodies, organized spatially within the cellular matrix, can be defined as the aggregation of soybean protein particles.

The globular protein aggregation bodies, primarily comprising glycinin and β-conglycinin, resemble spherical entities with small internal pores or channels. These structures form network-like structures that demonstrate regular and organized patterns.

However, Figure 4D presents a relatively blank microcosm of homogenized soy milk with minimal small particles. This substantiates the tailing phenomenon in the 1 to 10-micron range, as illustrated in Figure 2. These findings highlight that BeVision S1 can provide insight into the dynamic and complex nature of soybean protein aggregation at the microscopic level.

Figure 4. Examples of the microscopic results from BeVision S1. A&B: Results of unhomogenized soy milk under 10x objective. C: Zoom-in results with oversized particles of unhomogenized soy milk under 40x objective. D: Results of homogenized soy milk under 40x objective. Image Credit: Bettersize Instruments Ltd.

The undissolved soybean protein monomer particle size is typically 40 nm to 2 microns. As indicated in Figure 2, the particle size of sample 1 predominantly falls below 2 microns, whereas sample 2’s particles are significantly above 2 microns. The image analysis from BeVision S1 further confirms that these overly large particles in sample 2 are protein agglomeration.

These results reaffirm that unhomogenized soy milk is more susceptible to protein aggregation. In contrast, the homogenization process effectively decreases the overall particle size of components and disrupts large aggregates of soy proteins, enhancing the bioavailability of soy milk in the human body.

Conclusions

Homogenization is crucial in breaking down large fat globules and protein aggregates, yielding smaller and more uniformly dispersed particles within soy milk. This process significantly enhances the product's texture, stability, and overall quality.

By understanding the particle size distribution, manufacturers can monitor the homogenization process to attain desired sensory attributes, like mouthfeel and creaminess, and consistency in the final product.

Particle Detective: Hunting for Clues in Soy Milk

Video Credit: Bettersize Instruments Ltd.

This information has been sourced, reviewed and adapted from materials provided by Bettersize Instruments Ltd.

For more information on this source, please visit Bettersize Instruments Ltd.