Composite materials have revolutionized our industry, bringing outstanding performance to commonly used materials. However, designing these materials for maximum performance is not always intuitive.

Below, we’ve collected some particularly interesting examples of composite materials engineering and how the researchers managed to obtain the insight necessary for successful designs.

Image Credit: vitals/Shutterstock.com & W.Phokin/Shutterstock.com

Detecting fibers in a composite polymer

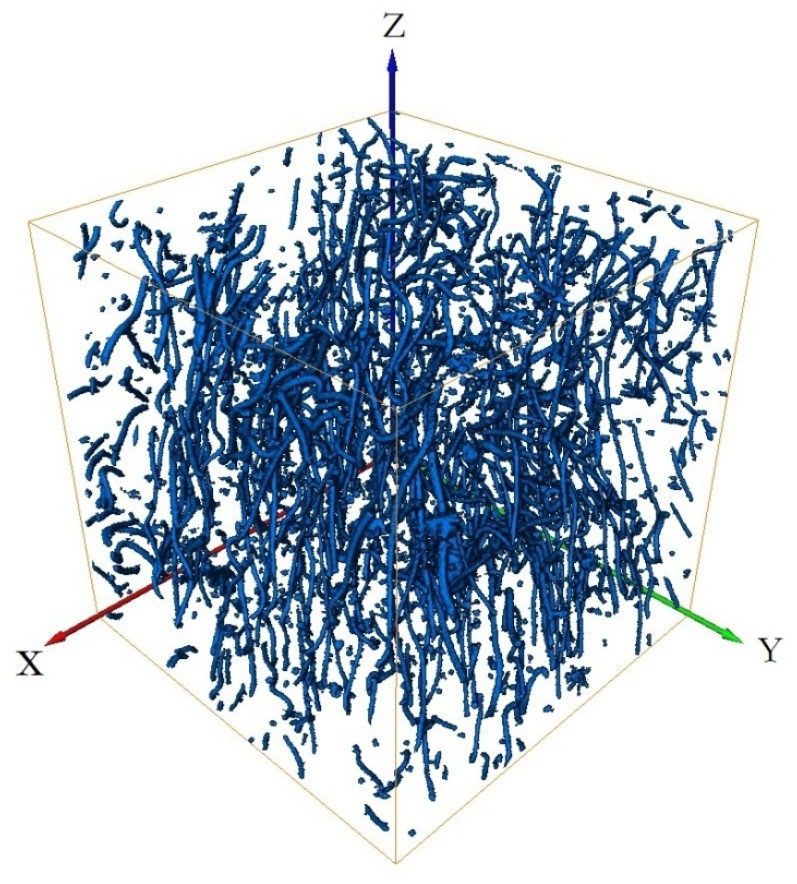

Benhui Yu et al. investigated and outlined an approach to determine and measure the distribution and orientation of fibers in a fiber-reinforced polymer.

First, they mixed polyester fibers into a rubber and black carbon mix. Then they scanned the resulting sample with an X-ray microscope and processed the dataset to detect and measure the contained fibers.

After correctly detecting the fibers with image processing software, they proceeded to quantify the distribution and orientation of the fibers.

Because these parameters are critical when designing materials with higher resistance to traction or compression stress, having a clear and standardized method to perform such measurements is key to optimizing the process of designing new materials.

Images of polyester short fibers reconstructed using Thermo Scientific™ Avizo™ Software. Image Credit: https://doi.org/10.3390/ma15103726

Cleaning our planet with science

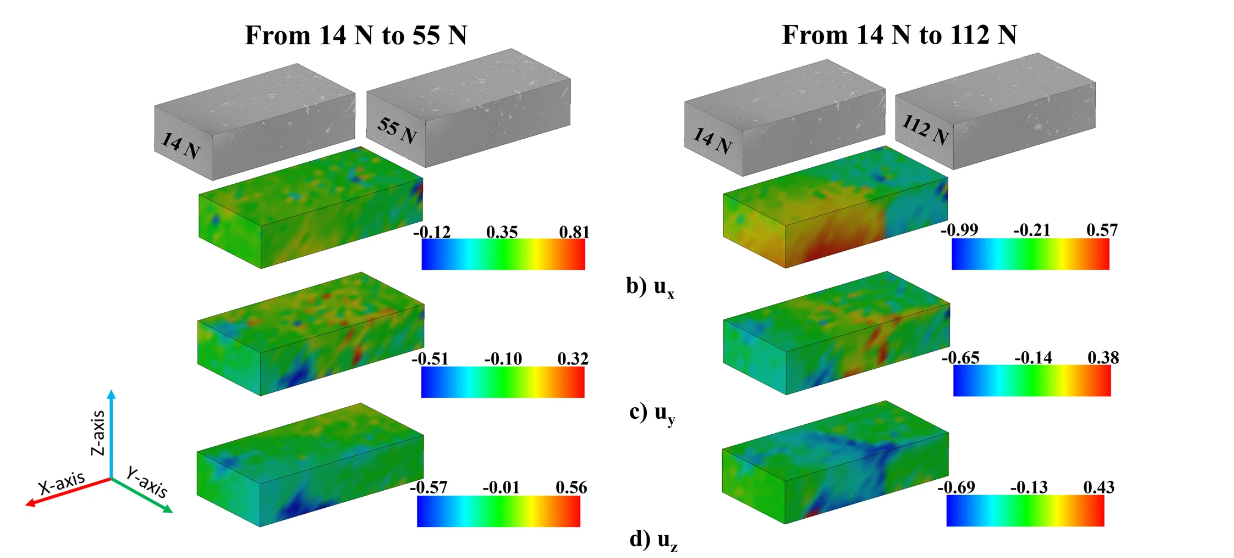

After the nuclear power plant in Fukushima, Japan, was devastated by a tsunami in 2011, the site was so dangerously radioactive that much of the cleanup had to be completed by robots.

To access the radioactive material, the robots first had to break the concrete mix that formed because of the high temperature reached in the core. The mix contained several materials that were used to build the plant and ultimately became a sarcophagus for the radioactive core.

To understand how to properly penetrate this layer, Charilaos Paraskevoulakos et al. investigated how cracks formed in a concrete sample approximating the material they expected to find on site. Using digital volume correlation analysis, they identified the amount of stress that needed to be applied to crack the materials and observed how the cracking pattern varied based on the force applied.

Axial displacements in the simulated material measured by DVC as weight was added during the stress test. DVC analysis was conducted using Thermo Scientific™ Avizo™ Software. Image Credit: https://doi.org/10.1038/s41529-022-00264-y

Bio-inspired material design

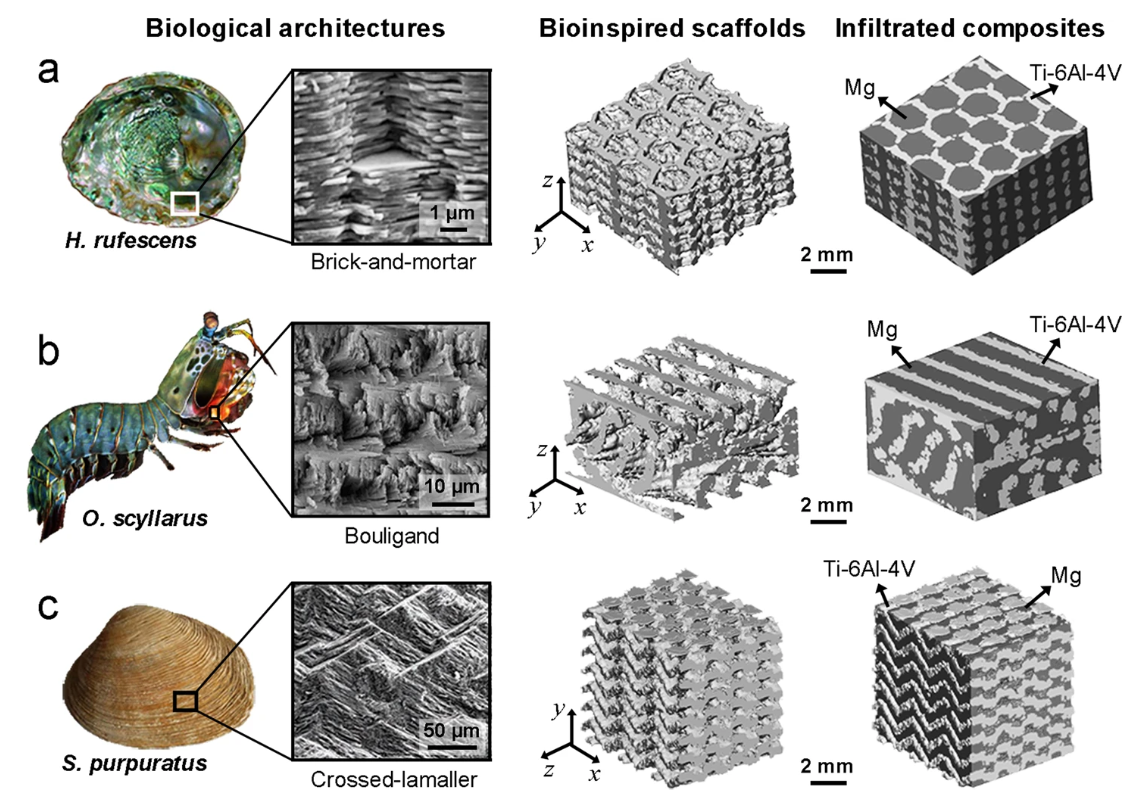

Mingyang Zhang et al.’s investigation of composite materials inspired them to look to the animal world, particularly how the microstructure of some animal shells provides a robust defense against predators.

The team replicated the shell structure found in some sea animals, replacing the original constituents with metallic alloys to obtain materials with incredible stress-resistance. After 3D printing a titanium alloy scaffold that they infiltrated with magnesium, they measured how the materials responded to stress and formed cracks.

The investigations on these bio-inspired materials reported a substantial improvement in the material response as well as a decrease in ductility.

The structures of the representative biological prototypes (sea snail, mantis shrimp, and clam) are displayed together with the brick-and-mortar, Bouligand, and crossed-lamellar architectures. Additionally, the bioinspired scaffolds and the infiltrated composites are shown. Image Credit: https://doi.org/10.1038/s41467-022-30873-9

Image processing: Unlocking the secrets of materials

All the research above was based on imaging and interpretation of representative samples. This work can easily become challenging when hundreds of fibers, particles, or cracks must be identified and monitored.

Image processing software like Thermo Scientific™ Avizo™ Software helps researchers make sense of their imaging datasets, simplifying the process and both extracting actionable information and generating reports from imaging data.

Learn more: Introduction to Avizo Software for composite materials characterization webinar

References and Further Reading

- Yu, B.; Ren, J.; Wang, K.; Wang, C.; Bian, H. Experimental Study on the Characterization of Orientation of Polyester Short Fibers in Rubber Composites by an X-ray Three-Dimensional Microscope. Materials 2022, 15, 3726. https://doi.org/10.3390/ma15103726

- Paraskevoulakos, C., Forna-Kreutzer, J.P., Hallam, K.R. et al. Investigating the mechanical behaviour of Fukushima MCCI using synchrotron Xray tomography and digital volume correlation. npj Mater Degrad 6, 55 (2022). https://doi.org/10.1038/s41529-022-00264-y

- Zhang, M., Zhao, N., Yu, Q. et al. On the damage tolerance of 3-D printed Mg-Ti interpenetrating-phase composites with bioinspired architectures. Nat Commun 13, 3247 (2022). https://doi.org/10.1038/s41467-022-30873-9

This information has been sourced, reviewed and adapted from materials provided by Thermo Fisher Scientific - Software.

For more information on this source, please visit Thermo Fisher Scientific - Software.