A lubricant's composition involves a carefully balanced blend of various elements, including base oils and additives, which collectively influence its performance and longevity during operation.

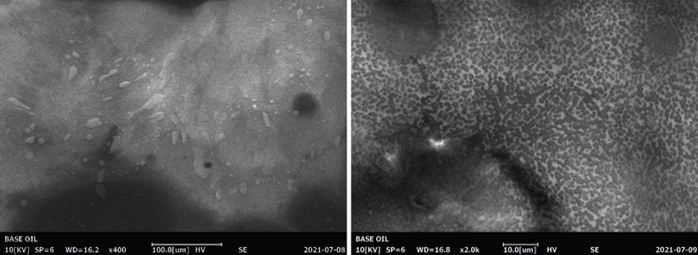

Figures 1-2. Crystallization of paraffins inside a lubricating oil with Pour Point -12 °C. SEM observation of the sample at 400x and 2000x magnification, at a temperature of -20 °C. Image Credit: COXEM Co. Ltd

Key requirements for lubricants used in motor vehicles or industrial machinery include minimizing friction and wear in mechanical couplings, dissipating heat generated by friction, and maintaining sufficient stability under all load and temperature conditions.

Viscosity is one of the key properties of lubricating oils. It characterizes the resistance that the fluid opposes to the mutual sliding of its particles and directly impacts the thickness of the oil film between the reciprocally moving metal surfaces.

Viscosity also reacts to temperature changes, generally increasing as temperatures drop. Excessive viscosity can lead to stiffening, which can have catastrophic effects on the machinery. This phenomenon occurs as lubricating oils solidify due to the crystallization of their paraffin wax components. The extent of viscosity change relative to temperature, i.e., the viscosity index, depends on the base oil type and the presence or absence of specific additives.

The pour point represents the lowest temperature at which lubricating oil retains its fluidity when cooled. It refers to the temperature 3 °C above at which the oil fails to flow inside a tilted container, which is then kept horizontal for five seconds, as outlined in ISO 3016, ASTM D97, and ASTM D6892-03 standards. This parameter is a qualitative index for the oil's minimum usable temperature. Below the pour point, the oil transitions from a liquid to a semi-solid state as the suspended wax crystals coalesce, impairing flowability characteristics.

Experimental Conditions for Observation with the Electron Microscope

Examining a lubricating oil that has been cooled to its pour point using an SEM electron microscope offers significant utility in studying and optimizing the oil and assessing its performance in low-temperature scenarios.

Using the Coxem Cool Stage accessory, a small droplet of oil is deposited into a specialized holder linked to a cooling system capable of reducing the sample’s temperature to -30 °C. This setup facilitates real-time observation of the sample under the SEM, allowing for analyzing its behavior over time or as the temperature decreases. Initially, the sample is cooled to -5 °C in ambient air, after which the chamber is sealed and brought to a vacuum state. Subsequently, the holder is cooled to the desired temperature, enabling observation of the sample while maintaining a low acceleration voltage (10–15 kV) to prevent the electron beam's alteration of the oil’s structure.

Figures 3-4. Cool stage accessory for Tabletop SEM. Image Credit: COXEM Co. Ltd

Time Lapse SEM Image Acquisition

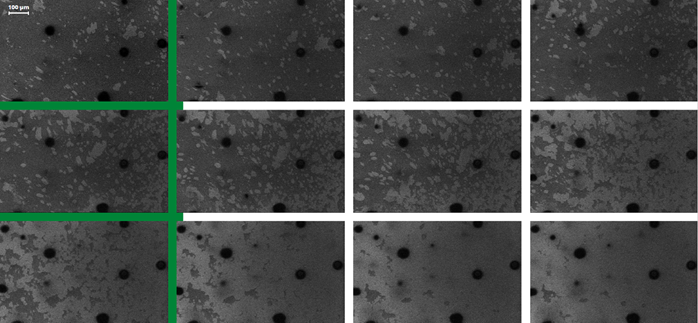

By employing a rapid scanning rate, it is possible to capture multiple consecutive images to reconstruct the behavior of the base oil sample over time at a constant temperature. Alternatively, as demonstrated in the provided example, the temperature can be gradually lowered at 0.2°C per second to observe the sample's response.

Figure 5. SE images were acquired at 2.5-second intervals on the base oil sample (having Pour Point = -12 °C), taking the sample from -10 °C to -15 °C (15 kV, 200x magnification). The growth and subsequent aggregation of paraffin crystals are observed, visible in light grey. Image Credit: COXEM Co. Ltd

The base oil sample under examination exhibits a pour point of -12 °C. By cooling the sample from -10 °C to -15 °C, it is possible to observe, using the SEM, the formation of small wax crystals suspended within the oil.

These crystals gradually enlarge and coalesce, forming a network that hinders oil flow. Further observation at higher magnifications (2000x) and a temperature of -20 °C reveals the paraffin crystals' distinct "leopard patch" structure.

Figure 6. SE image acquired on the base oil at a temperature of -20 °C (10 kV, 2000x magnification). We observe the network formed by the paraffin crystals that have aggregated into a rigid structure that limits the free flow of the oil. Image Credit: COXEM Co. Ltd

Evaluation of the Effectiveness of PPD Additives

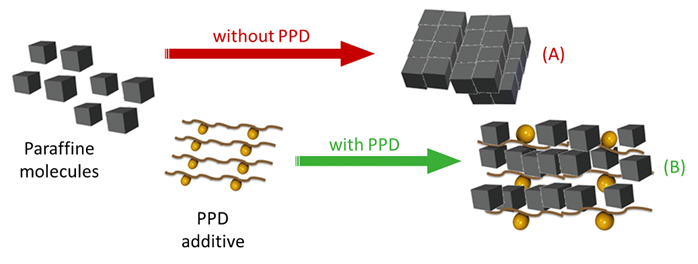

Pour point depressants (PPDs) are additives incorporated into lubricating oil formulations to decrease their pour point, enabling their application in extremely low temperatures. PPDs do not affect the temperature at which wax crystals begin to form, i.e., the cloud point or the quantity of wax that crystallizes. Instead, they modify the crystals' morphology and size, impeding their lateral expansion.

Figure 7. Operating mechanism of PPD additives. (A) Paraffin crystallization and formation of rigid networks: the oil can no longer flow. (B) Aggregation of paraffin crystals is prevented, leading to a random structure: the oil continues to flow. Image Credit: COXEM Co. Ltd

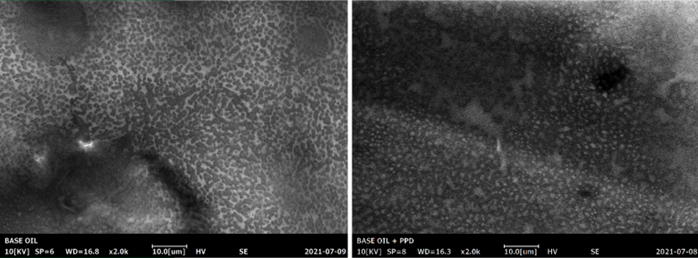

The research aims to assess the changes in the behavior of the lubricating oil under investigation following the incorporation of a PPD additive, which reduces its pour point from -12 °C to -30 °C. The SEM images presented in Figures 8–9 (10 kV, 2000x magnification) illustrate how, at the same temperature as the untreated oil (-20 °C), the presence of the PPD additive prevents the wax crystals from coalescing into a rigid network, enabling the oil to maintain its flowability.

Figures 8-9. SE images were acquired on the base oil as is (Pour Point -12 °C), on the left, and on the oil with PPD (Pour point -30 °C), on the right (10 kV, 2000x, -20 °C). Image Credit: COXEM Co. Ltd

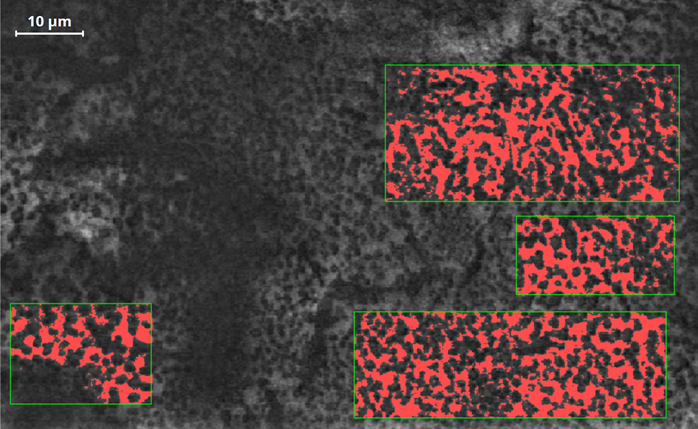

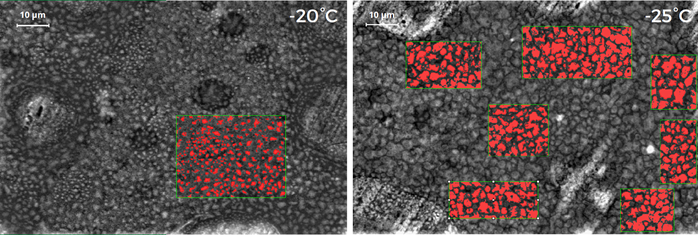

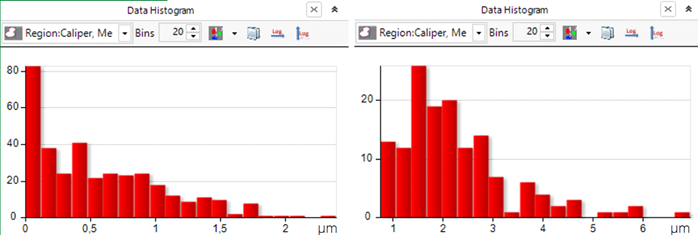

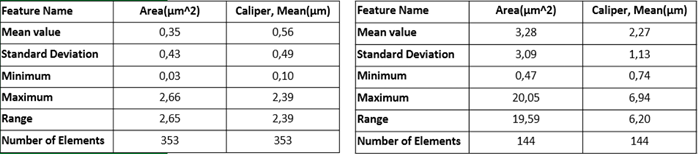

Following this, the lubricating oil treated with PPD was cooled to -25 °C, revealing continued growth of the wax crystals, albeit in an isolated and detached manner. This observation reaffirmed the effectiveness of the additive in reducing the oil’s pour point. Utilizing machine learning software, the SEM images were processed to measure the dimensions of the crystals at temperatures of -20 °C and -25 °C.

Figures 10-13. Automatic identification and measurement of the area and diameter of the wax crystals suspended in the oil with PPD additive, respectively at -20 °C (left) and -25 °C (right). Image Credit: COXEM Co. Ltd

Conclusions

The Coxem Cool Stage accessory enables the cooling of samples to -25 °C. With appropriate sample preparation and precise parameter selection for SEM analysis, diverse materials in both liquid and semi-solid states can be observed in real time, facilitating the examination of their behavior amid temperature fluctuations.

This information has been sourced, reviewed and adapted from materials provided by COXEM Co. Ltd.

For more information on this source, please visit COXEM Co. Ltd.