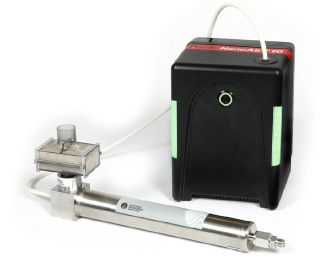

The NanoAir® 10 Condensation Particle Counter (CPC) is a groundbreaking new product developed by Particle Measuring Systems (PMS). It offers the sensitivity of a CPC with the simplicity and functionality of a conventional cleanroom particle counter.

It is engineered to monitor ultra-clean environments and provides 10 nm detection sensitivity at a sample flow rate of 2.8 L/min (0.1 CFM).

The ParticleSeeker® Smart Manifold is a 10-port manifold that offers key benefits to applications that require multiple sample locations. The manifold can be used to monitor both sequential and programmed sequences.

Image Credit: Particle Measuring Systems

This introduction Video provides an overview of the NanoAir 10 Condensation Particle Counter and ParticleSeeker® Manifold.

NanoAir™ 10 Aerosol Particle Counter

Video Credit: Particle Measuring Systems

This article addresses frequently asked questions alongside questions submitted during and after the webinar on the NanoAir® and ParticleSeeker® instruments. Product experts have answered the questions.

What is a Condensation Particle Counter (CPC) and How Does it Work?

A condensation particle counter (CPC) can measure the concentration of ultra-small particles that a traditional optical particle counter (OPC) cannot detect. The CPC instrument operates based on condensational growth. In this process, particles are enlarged by saturating them with a working fluid, making them large enough to be detected and counted by an OPC. The basics of a CPC, which are also explained in this video and this blog, are shown below:

- The CPC brings a sample stream at a known flow rate.

- The sample stream enters the saturator region where vaporization of the working fluid occurs The sample stream combines with the vaporized working fluid becoming fully saturated.

- The sample stream passes into the condenser region, cooling rapidly. The vaporized working fluid in the sample stream subsequently enters a state of supersaturation, where it condenses onto the particles, causing an increase in size.

- The sample stream enters an OPC where the cultivated particles scatter light and are counted.

Where Would I Use a Point-of-Use (POU) Particle Counter (like NanoAir 10) versus a ParticleSeeker Manifold System Connected to a Sensor?

The ParticleSeeker manifold is an excellent choice for reducing the cost per sample point when overall trend monitoring is enough. The ParticleSeeker manifold is ideal for monitoring multiple sample locations in applications requiring sequential or programmed sequence. This manifold is unique insofar as it makes it possible to monitor process tool equipment Front End Module (EFEM) mini environments from the inside. Together, the ParticleSeeker and NanoAir instruments make it possible to monitor up to 120m2 of fab/process space when using all 10 manifold ports.

If a location is considered critical, a point-of-use particle counter should be used. When sampling through a manifold, particle losses will be less visible in certain locations due to particle transport and non-continuous sampling, potentially leading to an increased probability of missing an event. Therefore, this is not recommended for critical locations.

What Sampling Considerations Need to be Thought About When Looking at Particle Losses Because of Transport

There will always be particle losses wherever sampling tubing is used. While the ideal solution would be to not use any tubing and have the particle counter sampling directly from the area of interest, this is not always possible due to factors such as ease of access or space available.

Therefore, the aim should be to minimize tubing as much as possible. When looking at larger particles, particle losses are driven by momentum. If possible, the aim should be to minimize the number of bends and corners and run the tubing vertically. For particles in the nano-size range, particle losses are influenced by diffusion rather than momentum, so they will be impacted much less by tubing bends than larger particles.

How do Nano-Sized Particles Behave Differently from Larger Particles?

Particles in the nano size range are influenced by diffusion/Brownian motion, as the smallest nanoparticles are closer to the size of air molecules. Therefore, they occupy space between air molecules more easily. They can move or diffuse readily between the air molecules rather than being transported with the airflow, like with larger particles. Therefore, they can diffuse out of the flow and sometimes travel upstream and against bulk airflow for instance, which is something larger particles do not do.

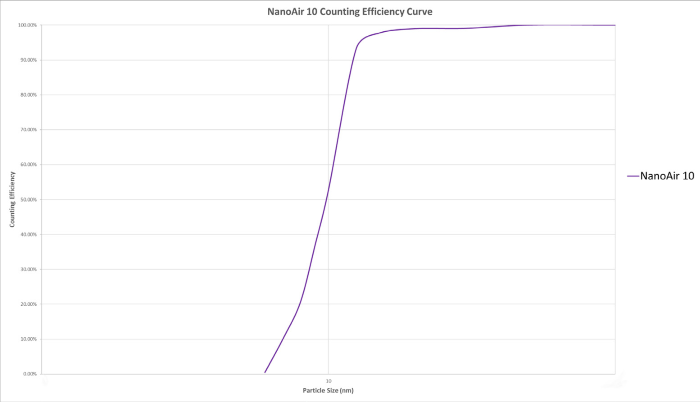

What is the Counting Efficiency of the NanoAir 10 at 10 nm?

The counting efficiency is around 50% at 10 nm. The NanoAir 10 instrument can achieve ~90% counting efficiency at 11 nm, then ~97.5% at 12 nm, and 100% counting efficiency at 15 nm and larger.

Figure 1. NanoAir 10 CPC Counting Efficiency Curve. Image Credit: Particle Measuring Systems

What Considerations Should be Made When Examining the Working Fluid of the NanoAir 10 Unit, Especially for In-Tool Monitoring?

No special considerations are necessary. NanoAir's working fluid is an amalgamation mix that is non-AMC and VOC-generating. It is also non-toxic and not hazardous. An SDS is available upon request.

Do Filters Handle Nano-Sized Particles?

Filters are very effective and efficient at removing nanoparticles. Because nanoparticles demonstrate high levels of motion due to diffusion, they are likely to be removed from the flow when they run into the filter media. Therefore, there is a high probability that nanoparticles are being generated inside the tool or cleanroom rather than being able to pass through a filter completely.

Where do Nanoparticles Come From, Whether in a Cleanroom Environment or Inside a Tool?

First, a significant source of particles in clean rooms comes from human activity; walking, talking, and even breathing can produce many particles, including nano-sized particles. Furthermore, particles can come from skin flakes, hair, clothing fibers, and other personal belongings.

Secondly, nanoparticles can be produced by any process that has moving parts. Certain manufacturing processes, like cutting, grinding, or abrading materials, can produce nanoparticle byproducts. The friction between the moving parts will generate some particles; this may be through mechanical wear and friction (such as from moving parts or surfaces rubbing against each other).

Construction materials inside the tool or cleanroom can also be a significant source of particle generation. This includes things like ceilings, floors, walls, filters, and other fixtures. Degradation of such materials, filter efficiency, and/or improper maintenance can cause a particle release within the cleanroom environment.

Moreover, airborne molecular contamination (AMCs) can be an attributable source of nanoparticles. Chemicals used and/or present in the cleanroom interact with each other and/or change states, causing spontaneous nanoparticle formation.

Reactions between different gas phases, such as acids and bases, can cause reaction products to form a physical precipitant that can aggregate to form nanoparticles. The presence of other devices, such as ionizers, can also cause reactions in the cleanroom and thus could be a source of nanoparticle formation.

Is Particle Detection in a Vacuum Possible With PMS Products? What About at High Heat or in Plasma Applications?

The NanoAir particle counter and Airnet particle counter cannot sample particles from a vacuum because no method exists to transport the particles into the particle counter (the flow into the particle counter would display as zero). The sample pressure should be as close to ambient pressure as possible to ensure the sample flow rate is accurate.

The NanoAir particle counter sample air temperature should be between 10 and 32 °C, so high-heat applications are not possible.

Would the Aerosol Monitoring be Particle-Size Exclusive?

The NanoAir particle counter can count all particles larger than 10 nm but does not differentiate between particle size (one size channel). The AirNet II 201 particle counter counts all particles larger than 200 nm and has four size channels (200 nm, 300 nm, 500 nm, and 1 micron).

Can the Particle Counter Measure at Pressurized Chamber?

Yes, but the HPD-III (High-Pressure Diffuser) accessory must be installed to vent excess pressure. Importantly, the gas must be inert, non-toxic, and non-flammable (CDA, Nitrogen, Argon) as it will be vented into the surrounding environment.

Image Credit: Particle Measuring Systems

You State the Particleseeker Manifold Can Be Quasi-Simultaneous in Ensemble Mode and Can Use Up to 6 M of Tubing. In This Configuration, Is the Total Flow Rate Still 0.1 Cfm? Does It Get Split Between the 10 Points?

The NanoAir particle counter’s sampled flow rate is 0.1 CFM, but it pulls an additional 2 CFM to function as a cooling flow, so the total flow rate for the NanoAir sensor alone will be 2.1 CFM.

When combined with the ParticleSeeker manifold, an additional “sheath” flow is divided between all the sample tubes that are not being sampled. This produces a total flow rate of around 4.1 CFM for the NanoAir and ParticleSeeker instruments.

Can the Particle Counter Replace PWP (Particle-per-Wafer-per-Pass) for Particle-On-Wafer Monitoring?

The NanoAir 10 particle counter detects airborne particles that could be deposited onto the wafer but does not count particles already present on the surface.

This information has been sourced, reviewed and adapted from materials provided by Particle Measuring Systems.

For more information on this source, please visit Particle Measuring Systems.