Cleanroom Requirements Overview

Modern manufacturing techniques frequently require clean environments designed, constructed, and maintained to facilitate the highest production yields possible while also meeting predictable throughput targets. This typically involves achieving a specified cleanroom classification to determine the level of cleanroom performance and subsequent maintenance efforts that are efficient and practical. Good, reliable particle detection equipment for this application is central to accomplishing these tasks.

Cleanroom certification necessitates the use of highly sensitive particle counters during the initial certification phases. Later, these same particle counters will be called upon at specific recertification time intervals. Certification data acquisition requires data from prescribed area locations, as detailed in the relevant certification standards.

Maintenance and troubleshooting efforts usually require a customized approach that does not need to comply with the prescription of any particular standard but instead depends on the experience of the cleanroom owners to mark the areas of interest and determine the optimal data collection frequency.

Image Credit: Particle Measuring Systems

Tailoring Solutions for an Evolving Industry

Cleanroom owners are responsible for choosing the appropriate collection schemes that make the most sense to facilitate factory yield optimization without impacting the factory's normal operations.

Collection generally includes continuous real-time methods that can acquire data from sensors in static locations throughout the factory 24/7. This offers reliable snapshots of cleanroom performance and insightful trends at those locations over time. However, maintaining and troubleshooting efforts also demand more than simply using mobile “counter-on-a-cart” configurations and the data static sensor locations can supply.

The HandiLaz® Mini II handheld particle counter is a powerful and agile solution for the following scenarios:

- Pre-certification to determine a baseline of an area’s particle counts and gain quick insights into the preliminary data that supports the timing of an actual certification effort.

- Determining where potential hotspots may occur, i.e., where high particle counts may present challenges that should be addressed before taking any more costly certification efforts.

- Troubleshooting in high particle density areas to support certification and maintenance by supplying high spatial-resolution data to locate particle sources accurately.

- Sufficient data collection capabilities during the ongoing area mapping at planned sustainment intervals.

- Verify that laminar airflow schemes are effectively capturing and eliminating particle counts from propagating to cleaner areas.

This article outlines a few of the many applications across various industrial sectors and applications, including Automotive and Aerospace, clean manufacturing (> ISO 5), Semiconductor Fab (ISO 1 through ISO 5), Process Tool OEM, LED/ LCD, Materials, Medical, and Pharmaceutical Manufacturing.

The HandiLaz Mini II’s features equip cleanroom control personnel with improved detection capabilities at all stages of cleanroom control, including certification and maintenance, excursion response with pinpoint accuracy, filter and parts testing, and general manufacturing preparedness.

The high sensitivity and versatile nature of the easy-to-deploy HandiLaz Mini II makes it versatile enough to use in scenarios that require increased efficiencies and yields, which translate directly to bottom-line results and personnel empowerment.

Image Credit: Particle Measuring Systems

Key Features and Performance Specifications

Sensitivity, Size Range, Repeatability

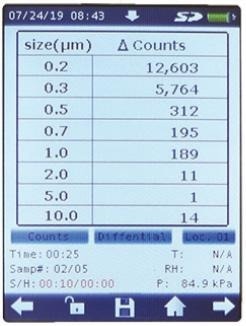

The performance specifications of the HandiLaz Mini II’s make it a best-in-class optical particle counter (OPC). It has precision with channel size resolution as low as 10 nm, applicable across size ranges from 200 nm up to 10 μm.

The internal Pulse Height Analyzer allows the user to configure each channel threshold manually, allowing the display of selectable channels. The instrument’s factory settings are calibrated with size thresholds of 0.2, 0.3, 0.5, 0.7, 1.0, 2.0, 5.0, 10 (μm).

Image Credit: Particle Measuring Systems

Reliable and repeatable, the particle counter's powerful internal circuitry design uses cutting-edge analog and digital signal processing, allowing for a flat response curve concerning room temperature and flow rate fluctuations. These compensations in the device’s circuity mean variability is less than 5% between particle count samples and a maximum concentration of 9,999,999 counts per cubic foot. Additional specifications are listed below.

Source: Particle Measuring Systems

| . |

. |

| Number of Channels |

8 standard, operator-adjustable. Data saved for 60 channels. |

| Size Range |

0.2 to 10 μm |

| Channel Thresholds |

0.2, 0.3, 0.5, 0.7, 1.0, 2.0, 5.0, 10.0 (10 nm resolution) |

| Light Source |

Laser diode (>10,000 hr) |

| Battery |

User-replaceable Li-Ion, 5 hour continuous counting, 10 hour intermittent counting |

| Data Storage |

1,000,000 samples |

| Operating RH |

5 - 95%, non-condensing |

| Error Messages (real-time) |

Count, Concentration, Low Battery, Coincidence Loss |

| Languages |

English |

| Warranty |

1 year |

| ISO 21501-4 |

Yes |

Portability and Ease of use

The HandiLaz Mini II is a portable, handheld OPC that weighs just 1.8 lb (0.83 kg) with compact dimensions of 3.2 x 5.4 x 1.7 in (8.2 x 13.7 x 4.2 cm). Moreover, the 3.5-inch Color LCD touchscreen interface is easy to use with its intuitive single-button start/stop functionality. Its Li-ion battery is rechargeable and can run continuously

for five or ten hours of periodic sampling use, and the laser diode for over 10,000 hours. Operating environments can have anywhere within 5% to 95% non-condensing relative humidity.

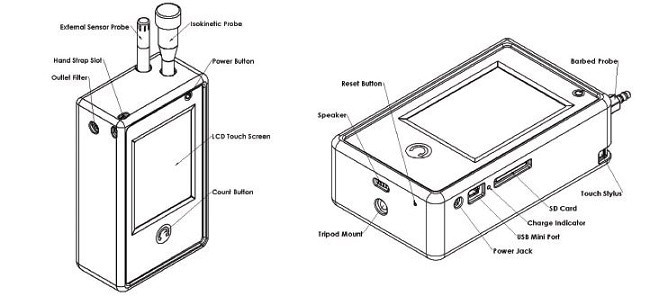

As a bonus, the integrated speaker can send sound message notifications for errors, count, concentration, low battery, and coincidence loss. The user can export all their monitoring data to a text file via external SD card and USB storage features, which come as standard in the HandiLaz Mini II.

External Sensors

The HandiLaz Mini II has an integrated temperature and a pressure sensor for flow rate compensation with a measurement range of 0 - 50 °C ± 0.1 °C. The counter can also accommodate the included external sensor probe that can be inserted into the headphone-style jack to facilitate 0-50 °C ambient temperature and 5-95% ambient relative humidity measurements.

Figure 1. Design Schematics. Image Credit: Particle Measuring Systems

Compact All-Contained Carry Case

Packaged in an ergonomically designed carrying case as standard, the HandiLaz Mini II includes the following accessories as standard: Barbed Probe; Isokinetic Probe; Inlet (zero-count) Filter; Power Supply; SD Memory Card (2 GB); Installed Temperature and Relative Humidity (TRH) Probe; USB Cable; USB Flash Drive (Documentation, Operations Manual); Inlet Caps (x2); Case Protector; Carrying Case; Inlet O-ring Seal Replacements (x4); and Calibration Certificate and Quick Guide.

Figure 2. Carrying Case Contents. Image Credit: Particle Measuring Systems

Applications Overview

Cleanroom Certification Preparation and Readiness

Cleanroom certification is perhaps the most time-intensive, laborious, yet vital activity for cleanroom control personnel. It often demands the expensive procurement of third-party suppliers to collect and report data.

Localized particle sources in particular locations routinely require remedy identification before the larger defined area can be properly certified. The compact and accurate HandiLaz Mini II allows engineers and technicians to perform a pre-certification gross particle check of almost any area to identify localized particle sources.

The particle source can then be isolated and either encapsulated or eliminated before conducting the official certification data collection, limiting the reiterative and costly “test-evaluate-modify-retest” cycles that a certification team may have previously employed to ensure a space is within particle limit specifications.

The HandiLaz Mini II can effectively collect a statistically relevant sample from a certification point location when approaching the official certification data collection phase. The results can support the user in determining whether an area will pass compliance during official ISO 14644 certification efforts when in a normal operating (manufacturing) state.

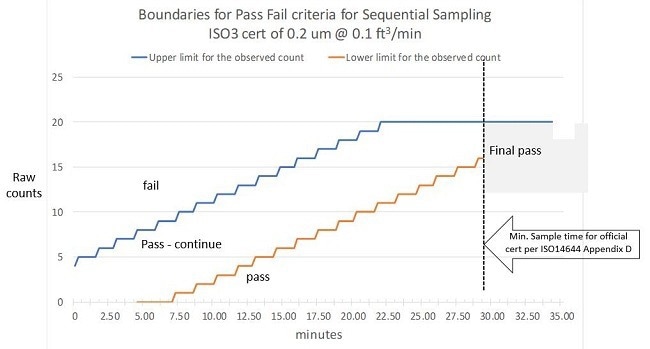

Appendix D of ISO 14644-1, “Sequential Sampling,” details a pass/fail criterion that allows the HandiLaz user to establish if an area will pass in a fraction of the time it would usually take to gather a full cubic meter of the cleanroom air sample.

The "Sequential Sampling” method significantly reduces the volume needed to certify an area. It determines a minimum required sample volume, which is predicated on the volume required to collect 20 particles at the certification particle size, based on the count thresholds seen in the ISO standard, as shown in Table 1.

Table 1. Certification particle size thresholds per ISO 14644-1. Source: Particle Measuring Systems

| |

0.1 µm |

0.2 µm |

0.3 µm |

0.5 µm |

1.0 µm |

5.0 µm |

| ISO 1 |

10 |

2 |

|

|

|

|

| ISO 2 |

100 |

24 |

10 |

4 |

|

|

| ISO 3 |

1,000 |

237 |

102 |

35 |

8 |

|

| ISO 4 |

10,000 |

2,370 |

1,020 |

352 |

83 |

|

| ISO 5 |

100,000 |

23,700 |

10,200 |

3,520 |

832 |

29 |

| ISO 6 |

1,000,000 |

237,000 |

102,000 |

35,200 |

8,320 |

293 |

| ISO 7 |

|

|

|

352,000 |

83,200 |

2,930 |

| ISO 8 |

|

|

|

3,520,000 |

832,000 |

29,300 |

| ISO 9 |

|

|

|

35,200,000 |

8,320,000 |

293,000 |

Larger certification particle sizes will need a considerably greater sample volume, thus longer sample times to ensure the necessary twenty particles are acquired for statistical significance; similarly, cleaner ISO certification levels also require larger sample volumes.

Table 2 summarizes the sample volumes required for ISO 3 and ISO 5 at various certification particle sizes. The HandiLaz Mini II can sample the 0.2 μm particle size, which brings in considerable time savings over a particle counter with a more limited range.

Table 2. Required sample volume for certification by ISO and certified particle size. Source: Particle Measuring Systems

| |

Certification Particle Size [µm] |

Required Sample Volume [ft3] |

Required Sample Time @ 0.1 CFM [min] |

| ISO 3 |

0.2 |

2.98 |

30 |

| 0.3 |

6.92 |

69 |

| 0.5 |

20.18 |

202 |

| ISO 5 |

0.2 |

0.03 |

0.3 |

| 0.5 |

0.20 |

2.0 |

| 1.0 |

0.85 |

8.5 |

ISO 14644 Appendix D describes the criteria for both upper and lower bounds for raw counts in line with sample time so that pass/fail predictions are reliable and can be made in real time. The predictions can be made before collecting the minimum sample volume at each sample point, which is necessary for certification or recertification for sustainment and maintenance.

Figure 3 illustrates the actual time-dependent pass/fail criteria for an ISO 3 area being assessed at the 0.2 μm particle size. A complete ISO certification determination is possible in less than 30 minutes (or 0.3 ft3 with the HandiLaz flow rate of @ 0.1 CFM). However, the upper bound on the raw particle counts may signify a pass/fail result well before collecting the minimum sample volume.

Figure 3. Pass/Fail Boundaries For ISO 3 CERT OF 0.2 μM @ 0.1 CFM. Image Credit: Particle Measuring Systems

Sequential Sampling Made Easy: “Standard Comparison Display”

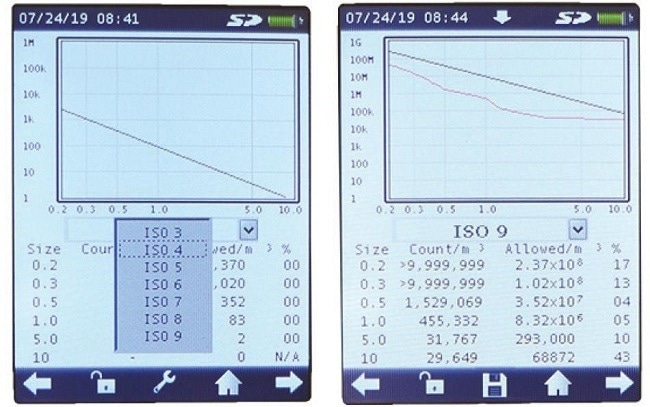

With the integrated Standard Comparison Display feature, the HandiLaz Mini II can assess certification readiness much more intuitively when using the sequential sampling scheme detailed in ISO 14644-1.

The Standard Comparison Display (Figure 4) makes the workflow easier and, as a real-time tool, shows how the particle data counts (normalized counts per cubic meter on the y-axis), which have been collected on a continuous basis, compared to the ISO 14644-1 counts threshold across the particle size channels (x-axis).

The size threshold shows the particle size channels as a black line, and the real-time normalized particle data during continuous sampling is displayed as a red line. Using this feature, the user can instantaneously determine which ISO level (and its FED 209E standard equivalent) can be accomplished at each sample point, and, if desired, until the minimum sample volume is acquired.

Figure 4. HandiLaz Mini II Standard Comparison Display. Image Credit: Particle Measuring Systems

Ad-Hoc Sustaining Point-of-Use Measurements

The most value-adding stage of cleanroom management begins once ISO certification efforts have been completed. During this “sustaining” or maintenance phase, manufacturing yields, and throughput can be optimized further.

Sample locations and frequencies should be selected to represent the efforts that are considered to be more value-added. Usually, sustaining data collection involves routine, periodic sampling in pre-established locations deemed as either key for product yield or in areas identified as vulnerable to particle excursion.

This regular interval sampling may be conducted for areas in 3D space that are not easily accessed by conventional particle counters but are ideal for the lightweight and portable HandiLaz Mini II.

Sustainment, or maintenance, often necessitates ad-hoc troubleshooting in areas flagged by yield indicators where a particle excursion may be ongoing. During these response troubleshooting exercises, it is worthwhile ensuring an agile monitoring solution, such as the HandiLaz Mini II, is on hand to identify local particle emission sources and pinpoint their origin.

Filter Testing and Leak Detection

Due to the different and diverse facility areas, particle counting with conventional particle counters can be challenging due to a sometimes unwieldy combination of size and weight. For the user, there is a significant advantage to be gained from being able to carry a particle counting device in one hand: it is easy to use and can be deployed in a wide variety of areas, including confined spaces, interstitial rooms, under raised-metal floors, chase areas, forced return air chases in sub-fab spaces, equipment rooms, laboratories, and many more.

The filters located in the HandiLaz Mini II's make-up air handlers and other return air filter banks can be tested for leaks, with or without an upstream filter challenge media, to qualify the parts from various manufacturers. After new filter installations, the periodic performance checks, as well as troubleshooting efforts, may show that the filter should be tested.

Mini-Environment / EFEM

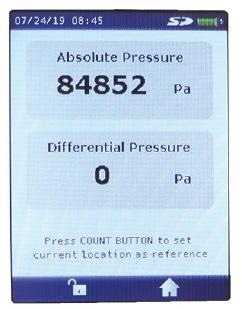

For inside monitoring of process tools, the HandiLaz Mini II can accurately detect particles at the 0.2, 0.3, 0.5, and larger particle size channels and measure the key point of use parameters within the process tool, including differential pressure and temperature.

Monitoring air pressure in various controlled environments can help determine if the airflow direction is acting as intended. After the single button below the main screen is pressed, the device can simply be moved around an area to read a differential pressure relative to the starting location.

Figure 5. Pressure Reading. Image Credit: Particle Measuring Systems

Industrial Application Examples

Due to ease of use, accuracy, precision, and agile deployment capabilities, the HandiLaz Mini II has been used successfully in several value-added applications across different industries and facility locations, including:

Source: Particle Measuring Systems

| Industry |

Facility Location |

| Semiconductor, LCD/LED, Laser Optics, Automotive/ Aerospace, OEM, Filter, Medical Mask |

Cleanroom Bay / Chase, Process Tool / Mini Environment / EFEM, Tool Exhaust, Under RMF, Subfab,Trench / Utility Area, Interstitial, MAH |

Summary

The manufacturing environment must be carefully controlled from a micro-contamination standpoint to optimize equipment performance and process efficiencies.

A key component of this is the capability to introduce a powerful and sustainable contamination control policy that demands active and reliable measurement before and beyond the initial certification of the controlled environment.

The HandiLaz Mini II allows the user to pre-qualify, verify, troubleshoot, and diagnose to expose existing or potential issues quickly so they can be resolved efficiently. This enables high yields and throughput while limiting overall facility downtime.

Cleanroom Verification Tool: Handilaz Mini II

Video Credit: Particle Measuring Systems

This information has been sourced, reviewed and adapted from materials provided by Particle Measuring Systems.

For more information on this source, please visit Particle Measuring Systems.